Beverage box customization and printing options turn ordinary beverage packaging into powerful brand tools. Custom beverage boxes enhance consumer engagement and boost brand recognition. Over 70% of shoppers say beverage packaging influences their purchase decisions, while interactive features like QR codes increase customer loyalty. Brands can choose from various materials, finishes, and printing methods to create unique beverages boxes, including specialized beverage subscription box solutions.

Impact Area | Statistic / Finding |

|---|---|

Sales growth from sustainable/custom packaging | |

Repeat buyers from personalized packaging | 59% |

Engagement via smart packaging | Enhanced loyalty and interaction |

Key Takeaways

Custom beverage boxes boost brand recognition and customer loyalty by combining unique designs, practical features, and sustainable materials.

Choosing the right materials and printing methods, like eco-friendly options and digital printing, helps create attractive, durable, and environmentally responsible packaging.

Adding special finishes and smart design elements enhances product appeal, protects beverages, and creates memorable unboxing experiences that encourage repeat purchases.

Beverage Boxes Overview

What Are Beverage Boxes?

Beverage boxes serve as essential containers for storing, transporting, and displaying drinks. Companies in the beverage industry use a variety of packaging solutions to meet different needs.

Glass containers offer durability and preserve beverage quality. They are highly recyclable and nonporous, making them a classic choice.

Plastic packaging remains popular due to its lightweight and cost-effective nature, although environmental concerns have led to increased scrutiny.

Paperboard boxes provide a sustainable option, mainly used for dairy and juices. These boxes are lightweight but often require special sealants.

Cans made from tin, steel, or aluminum protect beverages by preserving carbonation and freshness. They are also recyclable and widely used for products like sparkling water and wine spritzers.

Other common packaging forms include bottles, jars, pails, buckets, drums, and totes. Each type supports different beverage products, from single servings to bulk storage. Beverage boxes play a vital role in food and beverage packaging by ensuring safety and convenience.

Why Custom Beverage Packaging Matters

Packaging acts as a visual and emotional touchpoint, capturing attention and sharing brand values.

Colors, fonts, and graphics influence perception and create emotional connections with the product.

Iconic designs, such as unique bottle shapes, leave lasting impressions and build loyalty.

Features like resealable closures and ergonomic shapes improve convenience and encourage repeat purchases.

Packaging that matches product functionality, such as hydration trackers on sports bottles, strengthens engagement.

Sustainable packaging appeals to environmentally conscious buyers and supports premium pricing.

Storytelling through packaging deepens the relationship between consumers and brands.

Note: As the demand for sustainable and innovative packaging grows, brands must focus on custom solutions that reflect their identity and values. Beverage boxes with memorable designs and practical features can drive sales and foster long-term loyalty.

Box Types & Materials

Common Beverage Packaging Solutions

Many beverage packaging solutions exist to meet different needs. Companies often use cartons, carriers, sleeves, and luxury boxes for various drinks.

Cartons work well for juices and milk, offering lightweight protection.

Carriers, such as multipack cartons or basket carriers, help transport multiple bottles or cans together.

Sleeves add extra branding and protection for single bottles or cans.

Luxury boxes provide a premium feel for gift sets or specialty beverages.

Other innovative options include plant-based bottles, paper-based cartons, aluminum cans, and flexible drink pouches. These packaging types support both single-serve and bulk beverage packaging solutions.

Packaging Type | Typical Applications / Features |

|---|---|

Heavyweight Folding Cartons | Durable cartons for premium beverage packaging |

Bag-in-Box Packaging | Flexible packaging for bulk liquids, often used for wine or juice |

Litho-Laminated Cartons | High-quality laminated cartons for beverage protection and branding |

Packaging multiple beverage units together (e.g., basket carriers, clip-style multipacks) | |

Foodservice Packaging | Includes cold and hot cups, lids, and to-go food packaging for beverage service environments |

Microwave and Ovenable Packaging | Packaging designed for heating beverages safely in microwave or oven (e.g., trays, bowls) |

Material Choices

Manufacturers select materials based on durability, printability, and environmental impact.

Folding box board offers high durability and a smooth surface for custom boxes with vibrant graphics.

Natural kraft provides a natural look and moderate durability, making it suitable for eco-friendly packaging.

Coated unbleached kraft resists tearing and water, but has limited printability for special finishes.

Material | Durability | Printability | Environmental Impact | Notes |

|---|---|---|---|---|

Folding Box Board (FBB) | High | Excellent | Less eco-friendly | Premium packaging, costly |

Natural Kraft (SUS) | Moderate | Good | Eco-friendly | Food-safe, recyclable |

Coated Unbleached Kraft (CUK) | Moderate | Limited | Eco-friendly | Tear and water resistant |

Pros & Cons

Cardboard, paperboard, and eco-friendly materials each have strengths and weaknesses.

Biodegradable and recyclable materials support sustainability goals and align with customer values.

Lightweight custom boxes offer excellent protection and branding opportunities at a lower cost.

However, cardboard and paperboard can absorb moisture and may lack sturdiness unless treated.

Molded fiber packaging is compostable and microwave-safe, but sometimes contains additives to prevent sticking.

Note: Aluminum cans stand out as the most sustainable beverage container, as they can be recycled indefinitely without losing quality. Glass also recycles well but requires more energy due to its weight. Companies should consider both recyclability and the entire lifecycle when choosing custom boxes for beverages.

Customization Options

Size & Shape

Custom beverage box size and shape play a major role in how products stand out on store shelves. Brands can choose from a wide range of customization options to fit bottles, cans, or cartons securely. Custom boxes come in many shapes, from classic rectangles to unique, eye-catching designs that reflect a brand’s personality.

Customization includes box styles, materials, and finishes such as matte, gloss, embossing, and specialty textures.

Brands often add compartments, handles, or tamper-evident seals for extra functionality.

Unique shapes and colors help products attract attention and improve shelf presence.

Custom printed packaging boxes with logos and graphics boost brand recognition and make products memorable.

Custom packaging size and shape also improve convenience, making it easier for customers to carry bundled beverages.

Eco-friendly materials like cardboard, kraft, and corrugated board support sustainability and protect products.

Custom boxes not only protect beverages but also create a memorable unboxing experience. This emotional connection encourages repeat business and builds customer loyalty. High-quality custom packaging makes products look more premium and trustworthy, helping brands stand out in a crowded market.

Design Features

Effective packaging design combines both function and style. Brands use a variety of design features to enhance consumer appeal and strengthen brand identity.

Handles make beverage boxes easier to carry, improving user convenience.

Window cutouts allow customers to see the product inside, increasing visual appeal and exclusivity.

Custom tissue, inner boxes, and decorative elements like ribbons or printed cards add a personal touch and elevate the unboxing experience.

Custom printed packaging boxes often feature logos, bold colors, and modern graphics that reflect the brand’s message.

Smart packaging elements such as QR codes connect customers to extra content, boosting engagement.

Functional features like resealable closures and easy-open designs improve user satisfaction and encourage repeat purchases.

Brands like Malcantone Craft Brewery and Lostboy Cider use bold, colorful designs to attract trendy consumers. Others, like Olipop, include health tips or clear nutrition information to engage and inform buyers. Packaging design that balances beauty with practicality increases shelf presence and customer satisfaction.

Tip: Printing on all sides of custom boxes maximizes branding opportunities and ensures the product stands out from every angle.

Inserts & Dividers

Inserts and dividers are essential for protecting beverages during shipping and display. These features keep items secure, organized, and safe from damage.

Cardboard inserts provide sturdy support and are cost-effective for most packaging needs.

Foam inserts offer extra cushioning and can be custom cut for delicate bottles or cans.

Molded pulp inserts are eco-friendly and cushion fragile items, supporting sustainability goals.

Box separators and partition inserts create compartments, keeping multiple products separated and protected.

Custom-shaped inserts ensure a snug fit for specific products, enhancing both protection and presentation.

Paper inserts are lightweight, biodegradable, and customizable for branding.

Custom inserts and dividers not only prevent movement and collisions during transit but also contribute to the overall look of the packaging. Brands can print logos or add special finishes to inserts, reinforcing brand identity and improving the unboxing experience.

Finishes & Coatings

Finishes and coatings add both protection and visual appeal to beverage packaging. Brands can choose from several options to match their product and branding goals.

Finish/Coating Type | Description & Common Use Cases | Benefits |

|---|---|---|

Lamination (Matte & Gloss) | Plastic-coated covering for paperboard and corrugated boxes. Matte for luxury; gloss for vibrant look. | Strong protection against moisture and dust; matte offers a classy look; gloss is eye-catching. |

Gloss Varnish | Used for small to medium enterprises on corrugated boxes. | Shiny finish; cost-effective; suitable for shipping boxes. |

UV Coating | Creates a glossy look similar to gloss lamination. | High gloss grabs attention; adds visual appeal. |

AQ Coating | Water-based, food-safe coating for food containers and paperboard boxes. | Cost-effective; low gloss; safe for food; adds slight texture. |

Metallic Coating | Adds shine and a premium look, often for luxury rigid boxes. | Elevates product perception; protects contents; ideal for premium products. |

Specialty Coatings | Includes embossed, debossed, pearlized, scented, glittered, foil stamped, textured paper coatings. | Unique tactile and visual effects; enhances brand perception; used for luxury packaging. |

Protective Coatings | General category including lamination and varnishes. | Improves safety by strengthening box structure; protects against moisture and handling. |

Finishes like lamination and UV coating protect custom boxes from moisture and dust, while specialty coatings such as embossing or foil stamping add a luxurious touch. These options help brands create packaging that not only looks great but also keeps products safe during transport and storage.

Note: Customization in finishes and coatings allows brands to match their packaging design to their target audience, whether aiming for a premium look or a practical, food-safe finish.

Printing Techniques

CMYK & Pantone

Color plays a critical role in beverage packaging. Brands rely on accurate color reproduction to maintain consistency and build recognition. Two main printing options exist for color: CMYK and Pantone.

CMYK printing uses four inks—cyan, magenta, yellow, and black—to create a wide range of colors. This method works well for multi-colored images and large-volume runs. It offers versatility and cost-effectiveness, especially for designs with many colors or gradients. However, some shades may not match perfectly every time, and slight color variations can occur between print jobs.

Pantone printing uses pre-mixed spot colors. This system ensures precise color matching and high consistency, which is essential for brand-specific colors like logos. Pantone also allows for special effects, including metallics and fluorescents. The process requires separate print plates for each color, making it more expensive and less practical for short runs or complex designs.

Feature | Pantone Printing | CMYK Printing |

|---|---|---|

High consistency and accuracy, ideal for brand-specific colors | Medium consistency, slight color variations possible | |

Cost | Higher cost due to use of pre-mixed inks | Lower cost, suitable for bulk printing |

Color Range | Fixed colors with unique shades including fluorescents and metallics | Virtually unlimited colors through mixing |

Special Effects | Supports special inks like fluorescents and metallics | Limited special effects |

Versatility on Materials | Works well on diverse materials including paper, plastic, textile | Primarily suited for paper-based products |

Brands should choose Pantone for exact color matching and brand consistency, especially for custom packaging with strict color requirements. CMYK works best for cost-effective, multi-color designs and large runs. The choice depends on the desired color accuracy, budget, and production method.

Digital Printing

Digital printing has transformed custom box printing options for beverage brands. This method does not require plates or cylinders, which eliminates expensive setup costs. Brands can make instant design changes and start printing quickly. Digital printing supports lower minimum order quantities, making it ideal for small and medium runs.

Digital printing enables rapid prototyping and market testing. Brands can update designs quickly and print multiple versions in a single run.

The process delivers high-resolution, photo-quality graphics, which is perfect for premium packaging.

Digital printing supports variable data, allowing for personalized packaging, unique QR codes, or serialized barcodes.

The method is more eco-friendly, using water-based inks and reducing waste.

Brands can stay agile and respond to market trends with fast turnaround times.

Aspect | Digital Printing | Traditional Printing (Flexographic) |

|---|---|---|

Cost | Lower setup costs; cost-effective for small/medium runs | Higher setup costs due to plates; economical for large runs |

Speed | Faster turnaround; no plate setup required | Longer setup time; faster for large volume once running |

Flexibility | Supports variable data, personalization, multi-SKU runs | Less flexible; requires plates for each design variation |

Print Quality | High-resolution, sharp details, vibrant colors | Consistent color over long runs; less sharp on fine details |

Environmental Impact | Less waste; no plates; uses exact ink amounts | Plate waste in setup; more efficient on large runs |

Digital printing helps brands avoid large upfront investments and supports quick design iterations. For urgent or last-minute packaging needs, digital printing offers unmatched speed. For example, during major events, brands have used digital printing to produce and ship commemorative beverage packaging within a day. This flexibility makes digital printing a top choice for custom printed packaging boxes and custom packaging projects that require fast changes.

Specialty Effects

Specialty effects add value and distinction to beverage packaging. These custom options include spot UV, embossing, foil stamping, and soft-touch coatings.

Spot UV applies a glossy or matte finish to specific areas of the box. This effect highlights logos or graphics, increases shelf impact, and adds durability.

Embossing creates raised surfaces on the packaging. This tactile feature adds dimension and makes the box feel premium.

Foil stamping uses heat and pressure to apply metallic or pigmented foils, such as gold or silver. This technique signals quality and exclusivity, especially for luxury beverages.

Soft-touch coatings provide a velvety, fingerprint-resistant texture. This finish elevates the tactile and visual appeal, making the packaging feel luxurious. Studies show that packaging texture influences over 60% of purchase decisions in premium categories.

Tip: Specialty finishes like embossing and foil stamping help brands command higher price points and create memorable unboxing experiences. These effects work best on coated or textured stocks, which ensure clean impressions and sharp foil transfers.

Specialty effects not only improve the look and feel of custom packaging but also boost brand recall and customer loyalty. Brands can use these custom box printing options to align packaging with their vision and market positioning. In competitive beverage markets, these options help products stand out and attract attention.

Sustainable Beverage Packaging

Eco-Friendly Materials

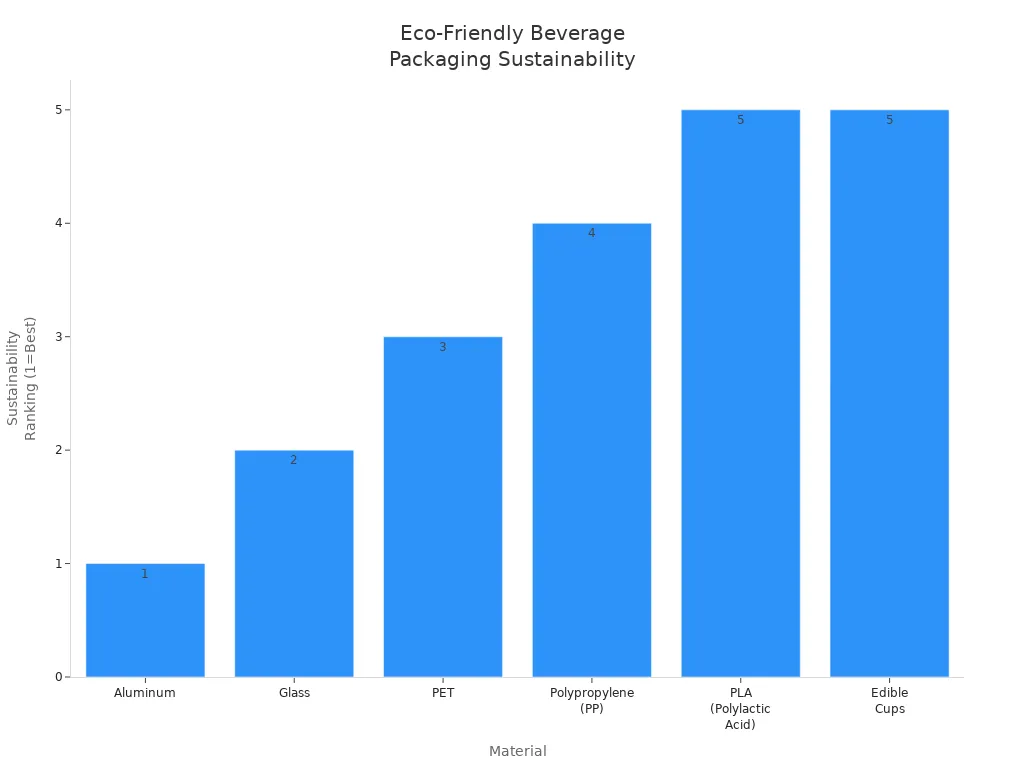

Sustainable beverage packaging uses materials that reduce environmental impact and support recyclability. Companies now choose options like PLA cups, which come from renewable resources such as corn starch or sugarcane. These cups break down within months in industrial composting, helping to cut plastic waste. Edible cups, made from seaweed or rice, offer zero waste because people can eat them or compost them after use. These new materials add to traditional choices like aluminum, glass, PET, and polypropylene, giving brands more ways to create environmentally friendly packaging.

Material | Recycling Rate | Recyclability | Carbon Footprint | Other Sustainability Factors | |

|---|---|---|---|---|---|

Aluminum | Over 70% globally | Can be recycled indefinitely without quality loss | Lower than glass and PET | Lightweight (reduces transport emissions), high circularity, energy savings in recycling | Most sustainable |

Glass | 100% recyclable | Reusable up to 25 times, but recycling less efficient | High (up to 6x higher than aluminum) | Heavy (increases transport emissions), energy-intensive production and recycling | Second |

PET | Around 13% (US) | Recyclable but quality degrades after recycling | Lower than glass | Lightweight, innovations in recycling improving sustainability, but currently moderate recycling rates | Third |

Polypropylene (PP) | Limited recycling infrastructure | Recyclable but less commonly recycled | Not specified | Versatile, moisture and heat resistant, sustainability depends on local recycling systems | Fourth |

PLA (Polylactic Acid) | N/A | Biodegradable and compostable in industrial systems | Low (biodegradable) | Made from renewable resources, breaks down in months under proper conditions | Emerging alternative |

Edible Cups | N/A | Biodegradable or edible | Zero waste | Made from natural ingredients like seaweed, rice; innovative and zero waste | Emerging alternative |

Companies that focus on sustainable packaging often see improved brand loyalty and meet growing consumer demand for environmentally friendly packaging.

Green Printing Methods

Green printing methods help lower the environmental impact of beverage box production. These methods include:

Using eco-friendly inks like soy-based, vegetable-based, or water-based inks to reduce air pollution and toxicity.

Choosing energy-efficient printing equipment to cut energy use and greenhouse gas emissions.

Selecting sustainable materials such as recycled paper or bamboo fibers for packaging.

Reducing waste by managing colors better and printing only what is needed.

Using renewable energy sources to power printing machines.

Recycling leftover paper, cardboard, and other materials from the printing process.

Brands that combine green printing with sustainable beverage packaging support both recyclability and sustainability. These innovations in beverage packaging help companies lower their carbon footprint and create packaging that meets modern environmental standards.

Design & Production

Artwork Prep

Preparing artwork for beverage packaging requires careful attention to detail. Designers should submit files in accepted formats such as AI, EPS, PDF, or INDD. These formats help maintain crisp lines and clear text. All artwork must use the CMYK color mode to ensure accurate color results during printing. Outlining all fonts prevents missing text issues, while embedding images avoids lost assets. Designers should keep artwork at least 0.125 inches away from cut and fold lines to respect dieline guidelines. Maintaining a minimum stroke thickness of 0.25pt ensures lines print clearly. Images should have a resolution of at least 300 PPI for sharp results. Special effects like Spot UV or foil stamping need separate layers. Communicating with packaging specialists helps address unique printing needs and color specifications. Following these steps leads to high-quality packaging design and smooth production.

Proofing & Samples

Proofing and sampling play a vital role in designing custom boxes. Companies often use several types of proofs and samples:

Type of Sample/Proof | Purpose and Benefits | Role in Beverage Box Design and Production Process |

|---|---|---|

Quick, cost-effective visualization | Validates design early and allows fast changes | |

3D Renderings | Realistic, interactive previews | Shows how artwork fits the packaging shape and aids collaboration |

Physical Samples | Tangible, accurate product mockups | Ensures quality, checks fit, and builds confidence before mass production |

3D renderings help teams spot design issues and improve communication. Physical samples allow for hands-on testing of structure and materials. Many packaging companies offer free design support, including expert advice and mockups. This support helps brands visualize their packaging and make changes before final printing. By using these tools, businesses can avoid costly mistakes and create effective custom packaging.

Choosing a Packaging Supplier

What to Look For

Selecting the right beverage packaging supplier shapes the success of any beverage brand. Companies should focus on several key criteria to ensure reliable and effective packaging. The supplier must offer materials that match the product’s needs, such as plastic for lightweight options, glass for a premium feel, or metal for strong protection. Durability, cost, and eco-friendliness remain important factors. Custom packaging solutions allow brands to stand out and meet specific requirements. Reliable suppliers provide certifications, flexible lead times, and strong customer service. The table below highlights essential considerations:

Criteria Category | Key Considerations |

|---|---|

Product Understanding | Match packaging to product type, shelf life, and sensitivity to light or oxygen |

Technical Criteria | Ensure protection, durability, and compatibility with production lines |

Commercial Criteria | Balance competitive pricing with quality and service; seek flexible agreements and technical support |

Sustainability | Use recycled or sustainable materials, follow circular economy principles, and hold certifications |

Supplier Capabilities | Offer customization, maintain certifications, provide reliable lead times, and deliver strong support |

Tip: Trusted beverage packaging suppliers help brands save time and select the best materials for their products.

Questions to Ask

Brands should ask targeted questions to evaluate a beverage packaging supplier’s capabilities and reliability. These questions help ensure the supplier can deliver safe, high-quality, and custom packaging.

What experience do you have with beverage packaging and can you share case studies?

Which packaging solutions and customization options do you offer?

How do you guarantee quality and comply with industry regulations?

What are your typical lead times and how do you manage supply chain disruptions?

Can you provide details about your sustainability practices and certifications?

How do you handle urgent requests or packaging problems?

What testing and validation processes do you use for packaging integrity?

A supplier who answers these questions clearly and confidently demonstrates strong technical expertise and customer service. Brands should also check for certifications like ISO or FDA approval and ask about material testing for safety and durability. Choosing a beverage packaging supplier with a proven track record ensures packaging protects products, supports branding, and meets market demands.

This guide shows that successful beverage boxes start with choosing strong materials, selecting the right printing method, and adding protective coatings. Custom beverage packaging shapes how consumers see a brand and builds loyalty through color, design, and storytelling. For the best results, brands should consult packaging experts or request samples before finalizing their packaging choices.