Custom two piece rigid boxes feature a sturdy base and a separate lid, crafted from thick cardboard or paperboard to deliver a premium look and feel. Luxury brands, retailers, and gift designers often choose two piece rigid boxes for their superior presentation and protection. The market for these boxes has grown rapidly, as shown below:

Data Point | Value |

|---|---|

Global luxury rigid box market (2023) | |

Projected market size (2034) | USD 6.70 billion |

Largest segment (2024) | Two piece rigid boxes |

Consumers value custom rigid boxes for their durability, safety during transit, and eco-friendly materials. Rigid two piece packaging combines elegance with strong product packaging, making it a top choice for brands that want to impress and protect. The two piece rigid box stands out for both its premium quality and its commitment to sustainability.

Key Takeaways

Custom two piece rigid boxes have a strong base and lid made from thick materials that protect products and give a luxury look.

These boxes are popular in luxury goods, electronics, cosmetics, and gifts because they combine style, safety, and sustainability.

Brands can customize size, shape, printing, and special features like magnetic closures and inserts to create unique packaging.

Two piece rigid boxes offer a premium unboxing experience that helps brands stand out and build customer loyalty.

Compared to folding cartons and corrugated boxes, rigid boxes provide better protection, durability, and a high-end appearance.

What Are Custom Two Piece Rigid Boxes

Definition

Custom two piece rigid boxes are premium packaging solutions made from thick, high-quality paperboard or cardboard. Each box consists of two separate parts: a sturdy base and a matching lid. This design gives products a luxurious presentation and strong protection. Brands often choose these boxes for items that require both elegance and safety, such as jewelry, electronics, cosmetics, and high-end gifts.

The construction of a two-piece rigid box uses advanced techniques. Manufacturers select cellulose-based paperboard, often made from virgin pulp, to ensure durability and a smooth finish. Lamination, which bonds a plastic film to the printed surface, protects the box from moisture, scratches, and wear. This process also makes colors more vibrant and gives the box a glossy, premium look. Empirical tests show that the shape and size of the panels affect how much pressure the box can withstand. For example, boxes with smaller panels resist compression better, which helps keep products safe during shipping.

Note: The use of renewable materials like cellulose not only improves strength but also supports sustainability, making these boxes a responsible choice for eco-conscious brands.

Key Features

Custom two piece rigid boxes stand out for their unique combination of strength, style, and versatility. Here are some of their main features:

Mechanical Strength: These boxes offer excellent compression resistance, which protects products during handling and transport. The McKee formula helps designers predict how much weight a box can handle, ensuring reliable performance.

Premium Materials: Most two piece rigid boxes use high-grade paperboard or cardboard. The choice of virgin pulp over recycled fibers increases durability and gives a smoother surface for printing and finishing.

Lamination and Finishes: Lamination adds a protective layer that guards against moisture and scratches. It also enhances the visual appeal by making colors pop and providing a high-gloss finish.

Customization Options: Brands can choose from a wide range of sizes, shapes, and finishes. Features like magnetic closures, lift-off lids, embossing, and luxury linings (such as velvet or satin) add to the premium feel.

Sustainability: Many custom rigid boxes use renewable or recyclable materials. This aligns with growing consumer demand for eco-friendly packaging.

Optimized Volume: Designers focus on optimizing the size of the box to improve distribution efficiency and reduce waste. This strategy benefits both the environment and the brand’s bottom line.

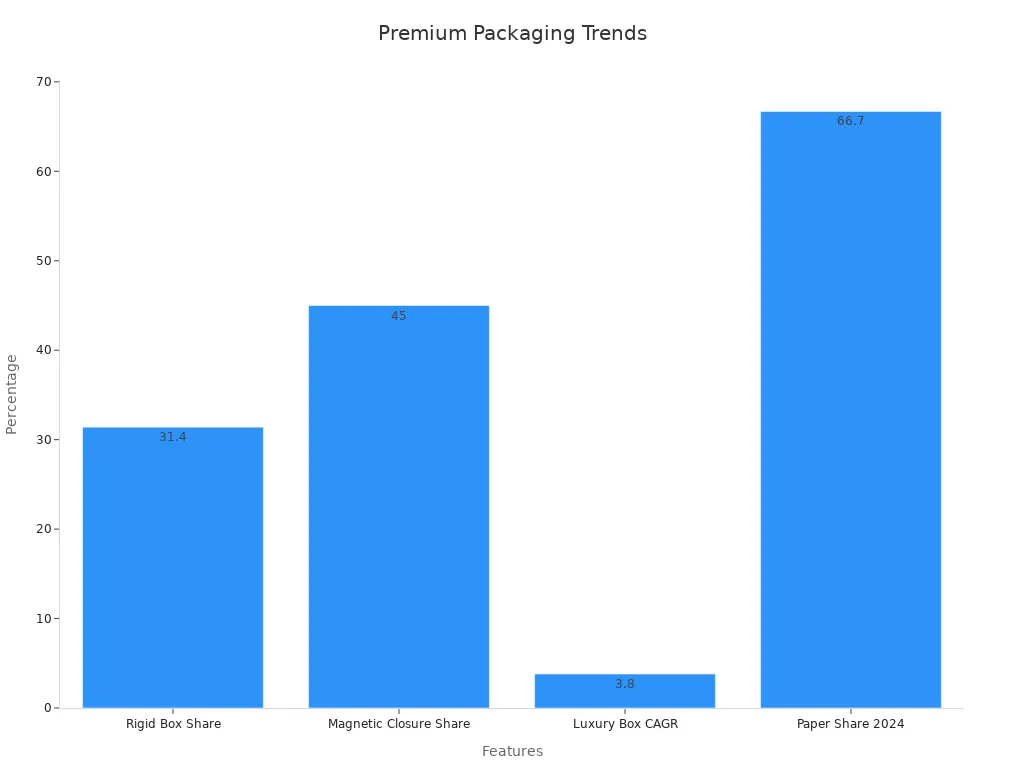

The popularity of two piece rigid boxes continues to rise, especially in luxury markets. The following chart shows the growing market share and demand for custom rigid packaging:

Statistic / Feature | Value / Percentage | Relevance to Customization and High-End Features |

|---|---|---|

Two-piece rigid boxes market share | Indicates prominence of two-piece design in the rigid box market | |

Magnetic closures market share | 45% | Shows high adoption of premium closure feature enhancing luxury appeal |

Luxury rigid box market valuation 2024 | $4.28 billion | Demonstrates significant market size for luxury packaging |

Projected market valuation 2034 | $6.20 billion | Indicates strong growth (CAGR 3.8%) driven by luxury sectors |

CAGR for luxury rigid boxes (2024-2034) | 3.8% | Reflects steady growth supporting demand for premium packaging |

Key sectors driving growth | Cosmetics, Jewelry, Electronics | Industries demanding high-end, customized packaging |

Paper and paperboard market share 2024 | 66.7% | Dominant materials supporting customization and premium finishes |

Many brands use custom two piece rigid boxes to create memorable unboxing experiences. Features like spot UV gloss, modular designs, and custom inserts help products stand out. Packaging influences over 70% of consumer buying decisions, so the right box can make a big difference. Two-piece boxes combine protection, style, and sustainability, making them a top choice for luxury and retail sectors.

Structure of Two-Piece Rigid Box

Base and Lid

Two piece rigid boxes feature a classic design with two separate components: the base and the lid. The lid slides smoothly over the base, creating a secure enclosure that protects the contents inside. This telescopic structure allows for easy opening and closing, which enhances the user experience. Many luxury brands prefer this style because it delivers both elegance and practicality.

Manufacturers use custom dimensions to fit each product perfectly. The base and lid can be tailored to any size, ensuring a snug fit for items like jewelry, electronics, or cosmetics. Some two piece rigid boxes include extra features, such as thumb cut-outs or tear strips, to make opening even easier. The secure fit of the lid over the base also helps prevent accidental openings during shipping or handling.

Tip: Brands often choose rigid boxes with magnetic closure for added security and a premium feel. This feature uses hidden magnets to keep the lid firmly in place, making the box ideal for high-value products.

The table below summarizes the main construction elements:

Construction Element | Description & Materials | Numerical/Measurement Details |

|---|---|---|

Base and Lid | Two-piece telescopic rigid box; lid slides over base for secure closure | Custom dimensions cut to client specifications |

Structural Features | Easy assembly, self-seal by air friction | Ensures product protection during shipment and handling |

Materials

Manufacturers select high-quality materials to create two piece rigid boxes. Most use rigid cardboard, chipboard, or specialty paperboard. Chipboard stands out for its strength and eco-friendly properties, as it is made from recycled wood fibers. The thickness and size of the material can be customized to match the product’s requirements.

Finishing options play a key role in the final appearance. Gloss, matte, and soft-touch matte finishes are popular choices. Some brands add UV coating, embossing, or debossing to highlight logos and text. Printing methods include offset, digital, and silk screen printing, using CMYK or Pantone colors for vibrant results. Many brands also use water-based inks to support sustainability.

Rigid boxes with magnetic closure, rigid drawer boxes, and book style boxes often use similar materials and finishes. These styles offer additional options for luxury packaging. Rigid drawer boxes provide a sliding mechanism, while book style boxes open like a hardcover book. Each style uses sturdy materials to ensure durability and a premium look.

Note: The use of recyclable chipboard and water-based inks helps brands meet eco-friendly goals without sacrificing quality.

Uses of Two Piece Rigid Boxes

Luxury Goods

Luxury brands rely on two piece rigid boxes to showcase their products with elegance and security. These packaging solutions protect high-value items such as jewelry, watches, perfumes, and designer accessories. The rigid box structure prevents crushing and damage, which is essential for delicate or expensive goods. Brands like Gucci, Hermès, and Christian Louboutin use luxury packaging boxes to reinforce their premium image and create memorable first impressions.

A well-designed two piece rigid box often features custom inserts, such as velvet or satin linings, that cradle each item securely. Embossed logos, foil stamping, and magnetic closures add to the sense of exclusivity. Many luxury rigid boxes with inserts help organize multiple components, such as necklace sets or watch collections, inside a single package. This attention to detail elevates the unboxing experience and encourages customer loyalty.

Note: The rise of e-commerce has increased the demand for protective and visually appealing packaging. Social media trends highlight luxury unboxing moments, making packaging a key part of the brand experience.

The table below summarizes market research on the effectiveness of two piece rigid boxes in luxury sectors:

Aspect | Evidence |

|---|---|

Market Share of Two-Piece Rigid Boxes | Projected to hold 31.5% market share in luxury packaging by 2025, favored for durability, elegant presentation, and exclusivity. |

Market Growth Forecast | Luxury rigid box market expected to grow from USD 4.4 billion in 2025 to USD 6.4 billion by 2035 at a CAGR of 3.8%. |

Key Demand Sectors | Cosmetics, electronics, and premium food & beverage brands represent the largest demand share. |

Brand Usage Examples | Gucci, Christian Louboutin (footwear); Hermès (fashion); Godiva, Neuhaus (chocolates); Apple (electronics); Chanel, Dior (cosmetics). |

Consumer Trends | Rising demand for premium, protective, and aesthetically pleasing packaging supporting unboxing experiences that boost brand identity and loyalty. |

Electronics and Cosmetics

Electronics and cosmetics companies choose two piece rigid boxes for their ability to combine protection with style. Devices like smartphones, headphones, and smartwatches require sturdy packaging solutions to prevent damage during shipping. Cosmetic brands, including Chanel and Dior, use luxury packaging boxes to present perfumes, skincare sets, and makeup collections in a way that feels exclusive and sophisticated.

Magnetic closure boxes have become especially popular in these industries. They offer both security and a smooth opening experience. Custom inserts hold each product in place, reducing movement and the risk of breakage. Many brands add features such as embossing, foil stamping, and spot UV finishes to enhance shelf appeal and brand recognition.

Rapid growth of e-commerce increases demand for secure and attractive luxury packaging.

Personalization and customization are major trends, with bespoke designs enhancing brand identity.

Luxury unboxing experiences are emphasized, leveraging tactile materials and unique opening mechanisms.

Packaging serves as a key brand experience element, differentiating products in competitive luxury markets.

Luxury rigid boxes with inserts help organize multiple items, such as skincare bottles or electronic accessories, within a single package. This organization improves the customer experience and supports the trend of gift-ready product packaging.

Gifts and Accessories

Gift and accessory brands use two piece rigid boxes to create a sense of anticipation and delight. These boxes are ideal for packaging jewelry, scarves, card decks, notebooks, and premium gift sets. The sturdy construction ensures that gifts arrive in perfect condition, while the elegant design adds value to the recipient’s experience.

Many companies select luxury packaging boxes with custom printing, ribbons, or textured finishes to match seasonal themes or special occasions. The versatility of two piece rigid boxes allows brands to tailor the size and shape for each product, from small trinkets to larger apparel items. This flexibility makes them a popular choice for both retail and personal care sectors.

Tip: Brands can use recyclable materials and water-based inks to create sustainable packaging solutions without sacrificing quality or appearance.

The continued growth of online shopping and social media sharing has made attractive product packaging more important than ever. Two piece rigid boxes help brands stand out, encourage repeat purchases, and support eco-friendly initiatives.

Benefits of Custom Rigid Boxes

Protection

Custom rigid boxes provide strong protection for products. Thick paperboard and sturdy construction help prevent damage from impacts or pressure. Many brands choose these boxes for fragile items like electronics or glassware. The secure fit of the lid over the base keeps contents safe during shipping and handling. This level of protection reduces the risk of returns and increases customer satisfaction.

Premium Look

A premium look sets custom rigid boxes apart from other packaging options. Smooth surfaces, sharp edges, and high-quality finishes create a sense of luxury. Many brands use embossing, foil stamping, or spot UV to highlight logos and designs. These features help products stand out on store shelves. Customers often associate this packaging with high value and quality.

Tip: A well-designed box can make a product feel more special and desirable.

Unboxing Experience

The customer unboxing experience plays a big role in modern retail. Custom rigid boxes open smoothly and reveal products in an elegant way. Many companies add custom inserts, ribbons, or tissue paper to enhance the reveal. This attention to detail creates excitement and encourages customers to share their experiences online. A memorable unboxing can lead to repeat purchases and positive reviews.

Sustainability

Sustainability has become a key factor in packaging decisions. Many custom rigid boxes use recyclable or biodegradable materials. Brands can choose water-based inks and eco-friendly finishes. This approach helps reduce environmental impact and appeals to eco-conscious consumers. Companies that use sustainable packaging often see improved brand reputation.

Benefit | Description | Example Use Case |

|---|---|---|

Protection | Prevents damage during shipping and handling | Electronics, glassware |

Premium Look | Enhances product value and shelf appeal | Jewelry, cosmetics |

Unboxing Experience | Creates memorable moments for customers | Gift sets, luxury items |

Sustainability | Supports eco-friendly business practices | All product categories |

The benefits of using custom rigid boxes include strong protection, a premium appearance, a memorable unboxing, and support for sustainability goals. These advantages help brands build trust and loyalty with their customers.

Customization in Custom Rigid Packaging

Size and Shape

Brands can select from a wide range of sizes and shapes when designing custom rigid packaging. This flexibility allows each product to fit perfectly, whether it is a delicate piece of jewelry or a set of luxury cosmetics. Custom rigid setup boxes can be made in square, rectangular, round, or even unique geometric forms. Companies often choose dimensions that reduce empty space, which helps protect items and lowers shipping costs. The ability to tailor the box size also supports efficient storage and display in retail environments.

Printing and Finishes

Custom printed rigid boxes offer brands a powerful way to express their identity. Advanced printing techniques, such as offset and digital printing, allow for vibrant colors and sharp graphics. Finishes like matte, gloss, and soft-touch coatings add a tactile element that enhances the customer’s first impression. Many brands use foil stamping, embossing, or spot UV to highlight logos and key details. These finishes not only attract attention but also reinforce the premium nature of rigid packaging.

Tip: Eco-friendly materials and water-based inks support sustainability goals while maintaining high-quality visuals.

The table below shows how tailored design and printing finishes can boost customer engagement:

Aspect of Custom Packaging | Case Study Example | Quantitative Impact | Qualitative Insight |

|---|---|---|---|

Personalized Labels | E-commerce subscription boxes with customer names vs. generic branding | 15% increase in subscription renewals | |

Custom-Designed Bags | Coffee roastery's limited-edition blends with unique bags | 30% higher repeat purchase rate | |

Individualized Messages | Skincare brand's holiday gift sets with personalized notes | 300% increase in brand mentions on social media | Customers share unboxing videos, enhancing brand visibility |

Inserts and Features

Custom rigid box packaging often includes inserts and special features that elevate the unboxing experience. Brands can add foam, molded pulp, or fabric-lined inserts to hold products securely. Some companies use windows, easy-open tabs, or handles for added convenience. Luxury brands sometimes include NFC chips or augmented reality elements, which provide authenticity checks and interactive experiences. These features create a sense of exclusivity and encourage customers to spend more time engaging with the packaging.

Custom rigid packaging offers infinite customization options, from structural design to decorative elements. This approach maximizes branding potential and helps products stand out in a crowded market. Brands that invest in unique packaging often see higher customer satisfaction and increased social media sharing.

Comparison with Other Packaging

Folding Cartons

Folding cartons serve as a popular choice for everyday packaging. Manufacturers use paperboard materials such as SBS (solid bleached sulfate), CUK (coated unbleached kraft), FBB (folded box board), and recycled paperboard. These cartons often feature surface coatings like gloss, matte, or water-resistant laminations. Printing techniques include offset lithography for large runs, digital printing for short runs, and flexographic printing for simple graphics. Finishing touches such as foil stamping, embossing, and spot UV add visual interest.

Folding cartons offer lightweight and cost-effective solutions.

They suit mass production and provide fast manufacturing times.

Their structural strength remains limited compared to rigid boxes.

Designs tend to be more utilitarian, with simpler finishes.

Packaging Type | Cost-Benefit | Durability | Aesthetic Appeal |

|---|---|---|---|

Custom Rigid Boxes | Superior impact resistance; crush protection; sturdy construction | Premium look and feel; enhances brand image; supports premium finishes like foil stamping and embossing | |

Folding Cartons | Cost-effective; suitable for mass production; faster manufacturing | Less durable; limited structural strength | More utilitarian; simpler designs and finishes; multiple printing and finishing options |

Custom two piece rigid boxes stand out with their thick, durable paperboard and decorative wraps. They resist collapsing, unlike folding cartons. Their solid chipboard base, premium finishes, and custom inserts provide superior protection and a memorable unboxing experience.

Corrugated Boxes

Corrugated boxes play a key role in shipping and bulk packaging. They use fluted paper layers sandwiched between liners, which gives them strength and cushioning. These boxes protect products during transit and storage, making them ideal for logistics and e-commerce.

Corrugated boxes excel in impact resistance and crush protection.

They handle heavy loads and rough handling.

Their appearance remains basic, focusing on function over style.

Custom printing is possible, but finishes are usually simple.

Custom two piece rigid boxes offer a different set of advantages. Their walls are typically four times thicker than folding cartons. Most use high-grade rigid board, often with 80–100% post-consumer recycled content. Features like foil stamping, magnetic closures, and velvet inserts create a luxury feel. These boxes elevate brand perception and provide strong product protection, especially for cosmetics, electronics, jewelry, and gifts.

Specification / Metric | Custom Two Piece Rigid Boxes | Folding Cartons | Corrugated Boxes |

|---|---|---|---|

Thickness | Thin paperboard | Multi-layer fluted board | |

Durability | Superior impact/crush resistance | Limited structural strength | High impact/crush resistance |

Aesthetic Appeal | Premium, luxury finishes | Simple to moderate finishes | Basic, utilitarian appearance |

Customization | Extensive (inserts, finishes, closures) | Multiple printing options | Limited finishes, basic printing |

Eco-Friendliness | Recyclable, sustainable materials | Recyclable, some coatings limit | Widely recyclable |

Industry Applications | Luxury goods, electronics, gifts | Food, retail, pharmaceuticals | Shipping, e-commerce, storage |

Note: Brands seeking premium presentation and strong protection often choose custom two piece rigid boxes over folding cartons or corrugated boxes. Each packaging type serves a unique purpose, but rigid boxes deliver the highest level of durability and visual impact for luxury products.

Custom two piece rigid boxes offer a sturdy base and lid, using thick materials for a premium look. Many brands use these boxes for luxury goods, electronics, and gifts. They provide strong protection, a high-end appearance, and many ways to customize. Sustainable materials make them a smart choice. Companies can boost product value and brand image by choosing this packaging.

FAQ

What makes two piece rigid boxes different from regular cardboard boxes?

Two piece rigid boxes use thicker, stronger materials. They have a separate lid and base. This design gives products a premium look and better protection. Regular cardboard boxes often fold and use thinner paperboard.

Can brands customize the size and design of these boxes?

Yes, brands can choose any size, shape, or color. They can add logos, special finishes, and inserts. Customization helps products stand out and supports brand identity.

Are two piece rigid boxes eco-friendly?

Many manufacturers use recyclable or biodegradable materials. Some brands select water-based inks and sustainable finishes. This choice helps reduce environmental impact and meets consumer demand for green packaging.

Which industries use custom two piece rigid boxes the most?

Luxury brands, electronics companies, and cosmetic firms often use these boxes. Gift and accessory brands also choose them for special packaging. These industries value protection, style, and a memorable unboxing experience.