Hot dog packaging that uses vacuum sealing or barrier films protects products during storage and transport, helping extend shelf life and reduce waste. Businesses see fewer damaged shipments. Consumers enjoy fresher hot dogs, while sustainable packaging hot dog options meet the growing demand for eco-friendly choices.

Key Takeaways

Vacuum sealing and modified atmosphere packaging keep hot dogs fresh longer by blocking air and bacteria, which slows spoilage and maintains quality.

Resealable packs and barrier films add convenience and protect hot dogs after opening, helping reduce waste and keep food safe.

Sustainable packaging options like biodegradable boxes support the environment while preserving freshness, meeting growing consumer demand for eco-friendly choices.

Why Packaging Matters

Preserving Freshness

Hot dog packaging plays a crucial role in keeping products fresh from the factory to the consumer’s table. Modern packaging methods, such as vacuum sealing and modified atmosphere packaging, help maintain the quality of hot dogs by reducing exposure to air and bacteria. Scientific studies show that these methods inhibit lipid oxidation, improve color stability, and prevent unpleasant odors. For example, packaging films coated with nisin, an antimicrobial agent, have proven effective in stopping the growth of harmful bacteria like Listeria monocytogenes on hot dogs. Bio-based packaging technologies, including antimicrobial films and coatings, also help extend shelf life by slowing down microbial growth.

Tip: Always store hot dogs below 40°F (4°C) and reseal packages tightly to maximize freshness.

A variety of factors can cause hot dogs to lose freshness. The table below shows how packaging addresses these challenges:

Factor Causing Freshness Loss | How Packaging Addresses the Factor |

|---|---|

Moisture loss | Airtight sealing prevents drying out |

Bacterial contamination | Hygienic barriers and secure seals |

Improper temperature control | Smart labels monitor temperature |

Exposure to air | Airtight packaging reduces spoilage |

Environmental concerns | Eco-friendly materials preserve freshness |

Preventing Spoilage

Spoilage remains a major concern for both consumers and businesses. Hot dog packaging helps prevent spoilage by creating barriers against oxygen, moisture, and contaminants. Vacuum packaging removes air, which slows the growth of spoilage bacteria and reduces rancidity. Modified atmosphere packaging replaces oxygen with gases like carbon dioxide and nitrogen, further protecting the product. Active packaging, which includes moisture absorbers and antimicrobial agents, controls microbial growth and drip loss.

Vacuum packaging and barrier films keep hot dogs safe by blocking bacteria and moisture.

Resealable packs and smart packaging help maintain quality after opening.

Packaging with high oxygen and moisture barriers prevents contamination and oxidation.

These innovations in hot dog packaging not only extend shelf life but also ensure that consumers enjoy safe, high-quality products.

Hot Dog Packaging Types

Choosing the right hot dog packaging helps keep food fresh, safe, and appealing. Different packaging types offer unique benefits for both businesses and consumers. Below, each method is explained with its main features and advantages.

Vacuum Sealing

Vacuum sealing removes most of the air from the package. This process slows down the growth of bacteria and prevents oxidation. As a result, hot dogs stay fresh for much longer compared to traditional plastic wraps. Vacuum-sealed packaging can extend the shelf life of meat products up to five times longer. It also protects against freezer burn and cross-contamination. However, vacuum sealing requires special machines, which can be a significant investment for businesses.

Note: Vacuum sealing works best when combined with proper refrigeration or freezing.

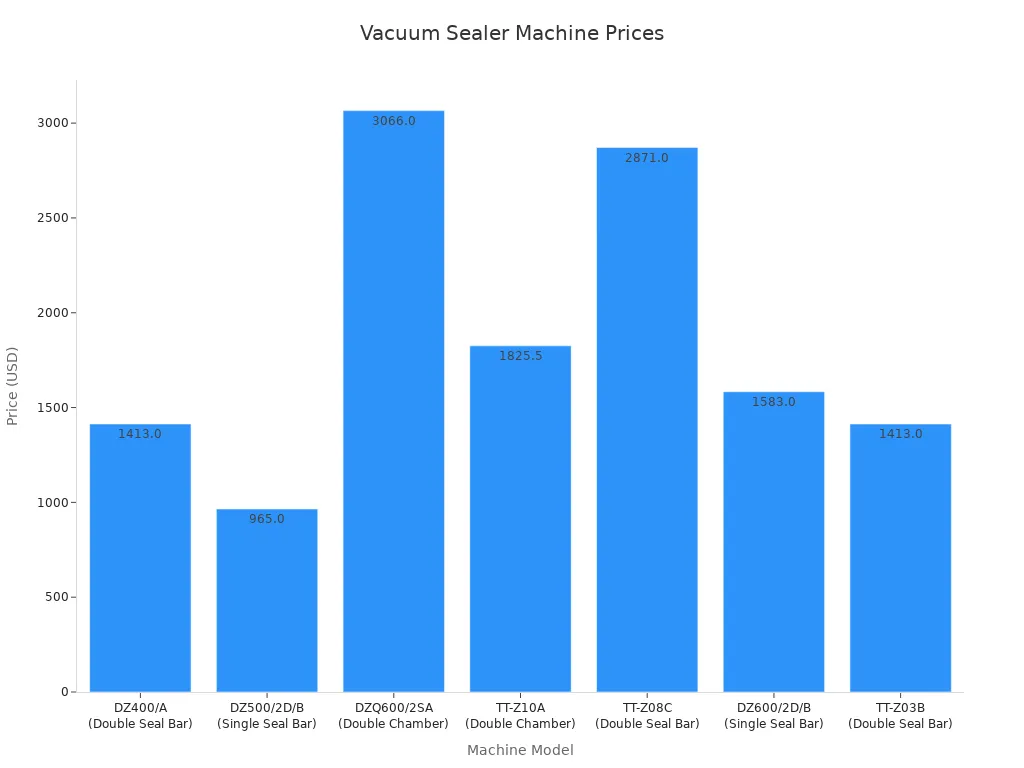

Machine Model | Price (USD) | Key Features | Power Consumption | Cycle Time |

|---|---|---|---|---|

DZ400/A (Double Seal Bar Table Chamber) | $1,413.00 | Stainless steel, optional gas flushing, 440x420x75 mm chamber | 0.9 KW at 220V | 10-25 seconds |

DZ500/2D/B (Single Seal Bar Stand) | $965.00 | Commercial vacuum packaging machine | N/A | N/A |

DZQ600/2SA (Double Chamber Gas Flush) | $3,066.00 | Double chamber, gas flush | N/A | N/A |

TT-Z10A (Double Chamber Vacuum Package) | $1,825.50 | Double chamber | N/A | N/A |

TT-Z08C (Double Seal Bar Stand Chamber) | $2,871.00 | Double seal bar | N/A | N/A |

DZ600/2D/B (Single Seal Bar Stand Chamber) | $1,583.00 | Single seal bar | N/A | N/A |

TT-Z03B (Double Seal Bar Table Chamber) | $1,413.00 | Double seal bar | N/A | N/A |

Modified Atmosphere

Modified Atmosphere Packaging (MAP) changes the air inside the package to a special mix of gases. For hot dogs, the most common mix is 70% nitrogen and 30% carbon dioxide. Nitrogen prevents spoilage by acting as an inert gas, while carbon dioxide slows down the growth of bacteria. MAP helps keep hot dogs fresh, maintains their color, and extends shelf life even more than vacuum packaging in some cases.

Aspect | Details |

|---|---|

How MAP works | Alters atmospheric composition inside packaging to extend shelf life, maintain quality, and inhibit microbial growth. |

Oxygen level | Kept low in processed meats like sausages to prevent oxidation and rancidity. |

Typical gas mixture | 70% Nitrogen (N2) and 30% Carbon Dioxide (CO2). |

Role of Nitrogen (N2) | Acts as an inert gas to prevent oxidative spoilage. |

Role of Carbon Dioxide (CO2) | Inhibits microbial growth. |

Effect on freshness | Controls oxygen to prevent spoilage and microbial growth, preserving freshness. |

Studies show that MAP with high carbon dioxide levels can inhibit bacteria, reduce oxidation, and keep hot dogs tasting and looking good for longer.

Resealable Packs

Resealable packs use plastic materials with zipper or snap closures. These packs allow consumers to open and close the package multiple times, which helps keep hot dogs fresh after the first use. Resealable packaging is lightweight, durable, and easy to carry. It also reduces waste by letting people use only what they need and save the rest for later.

Resealable packs protect against air, moisture, and contaminants.

They offer convenience for families and individuals who do not eat all the hot dogs at once.

The quality of the seal is important for maintaining freshness.

Tip: Always check that the resealable closure is fully sealed after each use.

Barrier Films

Barrier films use several layers of materials to block oxygen and moisture from reaching the hot dogs. The most effective films combine polyethylene (PE) for water resistance and ethylene-vinyl alcohol (EVOH) for oxygen protection. These films keep hot dogs from drying out or spoiling. Some advanced films use coatings like nanocellulose to further reduce oxygen and moisture transmission.

Barrier films are flexible, can be shaped to fit the product, and often include features like antifog or UV protection. However, most barrier films are made from plastics, which can have a higher environmental impact unless recycled or replaced with biodegradable options.

Paper & Kraft Boxes

Paper and kraft boxes are popular for serving and transporting hot dogs, especially in food trucks and quick-service restaurants. These boxes are lightweight, recyclable, and biodegradable. They provide good insulation, oil resistance, and leak-proofing, which helps keep hot dogs fresh and prevents messes.

Kraft paper boxes are customizable and can be printed with logos or designs.

Many boxes meet food safety standards and are compostable.

Paperboard trays and clamshell boxes offer different styles for various serving needs.

Aspect | Details |

|---|---|

Sustainability Trend | 65% of manufacturers offer compostable/biodegradable kraft paper or cardboard options. |

Material Standards | FDA/EC1935-compliant kraft paper (250–350 GSM) or food-grade cardboard. |

Barrier Properties | Grease-resistant coatings essential for maintaining product integrity. |

Performance Metrics | Leakage rate under 0.5%, crush resistance minimum 1.5kg, shelf stability 45+ minutes. |

Regional Demand | High demand in North America and Europe driven by eco-friendly regulations. |

Sustainable Options

Sustainable hot dog packaging uses materials like biodegradable cardboard, kraft paper, and sugarcane pulp. These options break down quickly in composting facilities and have a lower carbon footprint than traditional plastics. Many sustainable packages are certified by organizations such as the Forest Stewardship Council (FSC) or carry compostability labels like BPI or TÜV AUSTRIA.

Biodegradable and compostable boxes are cost-effective, especially when bought in bulk.

They support branding and marketing by showing a commitment to the environment.

Some sustainable options may have lower durability, but they offer strong environmental benefits.

Note: Look for packaging with certifications like FSC, BPI, or TÜV AUSTRIA to ensure true sustainability.

Comparison Table

Packaging Type | Effectiveness (Freshness) | Cost | Convenience | Sustainability |

|---|---|---|---|---|

Vacuum Sealing | ⭐⭐⭐⭐⭐ | $$ | ⭐⭐⭐ | ⭐⭐ |

Modified Atmosphere | ⭐⭐⭐⭐⭐ | $$$ | ⭐⭐⭐ | ⭐⭐ |

Resealable Packs | ⭐⭐⭐⭐ | $$ | ⭐⭐⭐⭐⭐ | ⭐ |

Barrier Films | ⭐⭐⭐⭐ | $$ | ⭐⭐⭐ | ⭐ |

Paper & Kraft Boxes | ⭐⭐⭐ | $ | ⭐⭐⭐⭐⭐ | ⭐⭐⭐⭐⭐ |

Sustainable Options | ⭐⭐⭐ | $ | ⭐⭐⭐ | ⭐⭐⭐⭐⭐ |

⭐ = Relative rating (1-5 stars), $ = Relative cost

Tips & Innovations

Storing at Home

Proper storage at home keeps hot dogs safe and tasty. Food safety experts recommend several steps to maximize freshness and prevent spoilage. The table below summarizes the most important tips:

Practical Tip | Explanation |

|---|---|

Refrigerate or Freeze Promptly | Store hot dogs immediately after purchase to keep them cold |

Avoid Room Temperature | Do not leave hot dogs out more than 2 hours (1 hour if above 90°F) |

Maintain Proper Temperatures | Fridge at ≤40°F; freezer at ≤0°F |

Use Opened Hot Dogs Quickly | Consume within 1 week after opening |

Freeze for Longer Storage | Freeze to keep quality up to 2 months |

Reseal or Use Airtight Bags | Prevent exposure to air and odors by resealing or transferring to airtight containers |

Label Opening Date | Helps track freshness and usage time |

Store Away from Strong Odors | Prevents hot dogs from absorbing unwanted flavors |

Check for Spoilage | Look for color changes, mold, sliminess, or bad smells before eating |

Many people make mistakes when storing hot dogs. Common errors include not refrigerating promptly, failing to use airtight containers, and misunderstanding date labels. Freezer burn often happens when hot dogs are not stored in freezer-safe containers. People should always check for signs of spoilage before eating.

Packaging Trends

The hot dog industry continues to advance with new packaging technologies. QuiltWave active microwave packaging, developed by Oscar Mayer, uses laminated pockets that expand in the microwave. This design heats both the hot dog and bun in just 35 seconds, improving convenience and keeping moisture away. The microwavable paperboard tray allows for a quick, ready-to-eat meal.

Eco-friendly packaging trends are also shaping the industry. Manufacturers now use compostable and biodegradable materials, such as plant-based plastics and recyclable containers. These changes help reduce environmental impact and appeal to consumers who value sustainability. Vacuum-skin packaging and frozen ready-to-cook formats extend shelf life and reduce food waste. Facilities that combine packaging with cold-chain systems often achieve higher value, showing the importance of innovation in this sector.

Recent advances in packaging, such as vacuum sealing and compostable trays, help reduce food waste and improve safety. Experts recommend choosing packaging that balances freshness, convenience, and recyclability.

Stay informed by following industry news and attending events to discover new solutions that support both quality and sustainability.