The best pre roll packaging safeguards cannabis products, meets strict regulations, and boosts brand value. Packaging plays a pivotal role in the cannabis industry, as 72% of consumers consider it important when making purchases.

With pre roll packages driving over $4.1 billion in sales, brands must select pre rolls packaging that stands out. Custom pre roll packaging gives businesses a competitive edge.

Key Takeaways

Choose pre roll packaging that protects freshness and safety by using airtight, child-resistant, and tamper-evident features to keep products potent and compliant with laws.

Design packaging to reflect your brand and attract customers by using clear labeling, eco-friendly materials, and unique styles that stand out on shelves and build trust.

Balance cost and quality by considering bulk orders, minimum quantities, and material choices to meet budget needs while maintaining product integrity and customer appeal.

Why Packaging Matters

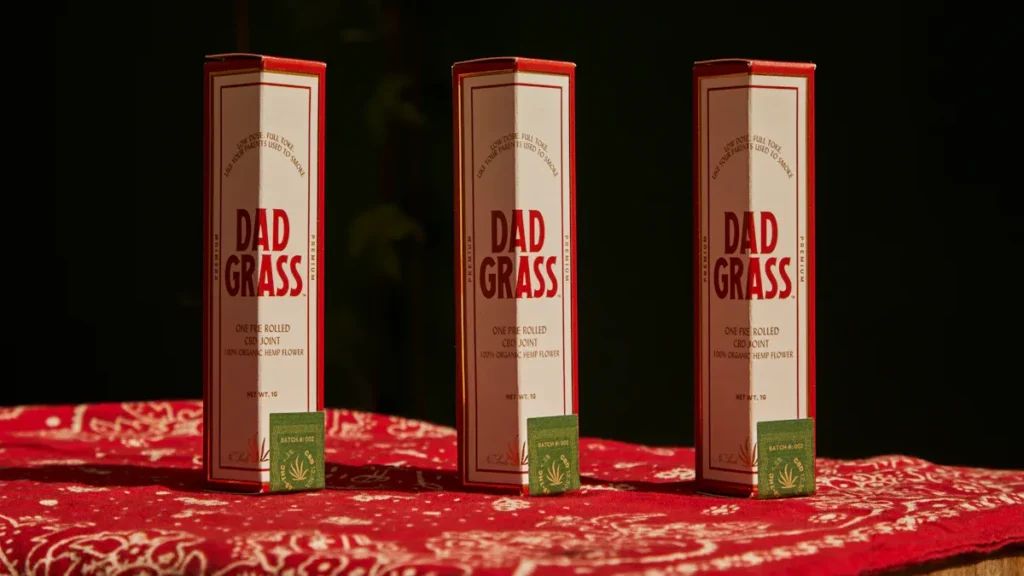

Brand Perception

Packaging shapes how consumers view a cannabis brand. Market research shows that packaging elements such as health claims, lifestyle imagery, and product type influence consumer attitudes. Packages with descriptors like “vegan” or “handcrafted” often suggest higher quality or healthiness. Many brands use nature scenes, food imagery, or even images of people and animals to create a specific brand personality. The table below highlights how different packaging elements affect consumer perception:

Packaging Element | Consumer Perception Impact |

|---|---|

Perceived as healthier, more socially acceptable; higher interest in trying and sampling. | |

Health Claims | Elicit positive emotions such as happiness and good feelings. |

Brand Personality Imagery | Increases product appeal, especially when showing lifestyle or natural themes. |

Product Protection

Pre roll packaging does more than attract attention. It protects the product from moisture, light, and oxygen. Airtight seals help preserve cannabinoids and terpenes, keeping the pre roll fresh and potent. High-quality materials like glass or aluminum tubes maintain product integrity and reduce contamination risk. Secure packaging also prevents mold growth and extends shelf life. Brands that invest in better packaging often see fewer returns and less waste.

Customer Decisions

Packaging plays a key role in customer choices. Many consumers notice if packaging is excessive or hard to open, which can affect their experience. Some appreciate recycling programs, but most worry about waste. Packaging size also matters. Large containers with small amounts of product may cause pre rolls to dry out faster. Clear product information and safety warnings help customers feel confident in their purchase. For many, packaging is a deciding factor when choosing between brands.

Audience & Compliance

Target Market

Brands must understand their target market before choosing pre roll packaging. Different groups have unique needs and preferences:

New cannabis users often choose pre-rolls for convenience and simplicity.

Experienced users value portability and easy sharing, especially in social settings.

Medical patients rely on pre-rolls for consistent dosing and ease of use.

Many consumers now seek quality, convenience, and a positive experience, even paying more for these features.

Eco-friendly packaging appeals to buyers who care about sustainability.

Younger buyers show steady or growing interest in pre-rolls, while their flower purchases decline.

Multi-packs have become popular, especially in Canada, where they make up most sales. In the US, single and multi-pack sales are more balanced.

Canadian buyers prefer larger pre-roll sizes, while US buyers often choose 1g joints.

Understanding these trends helps brands design packaging that meets customer expectations and stands out in the market.

Legal Requirements

Pre roll packaging must meet strict legal standards in every market. Common requirements include:

Opaque or translucent materials, often with matte finishes.

Clear warning labels and cannabis content indicators.

Limits on THC content per package.

Branding that does not appeal to minors.

Mandatory information such as business name, license number, batch numbers, and lab results.

Protection against contamination.

Meeting these rules keeps products safe and legal.

Compliance & Creativity

Brands can balance compliance with creative design. Many use custom shapes, colors, and tactile finishes to reflect their identity. Technology like QR codes or NFC tags adds engagement and information. Eco-friendly materials, such as recycled plastics or hemp paper, support sustainability goals. Creative labeling, embossing, and unique structures help products stand out while following regulations. Working with expert packaging providers ensures that pre roll packaging remains both compliant and memorable.

Types of Pre Roll Packaging

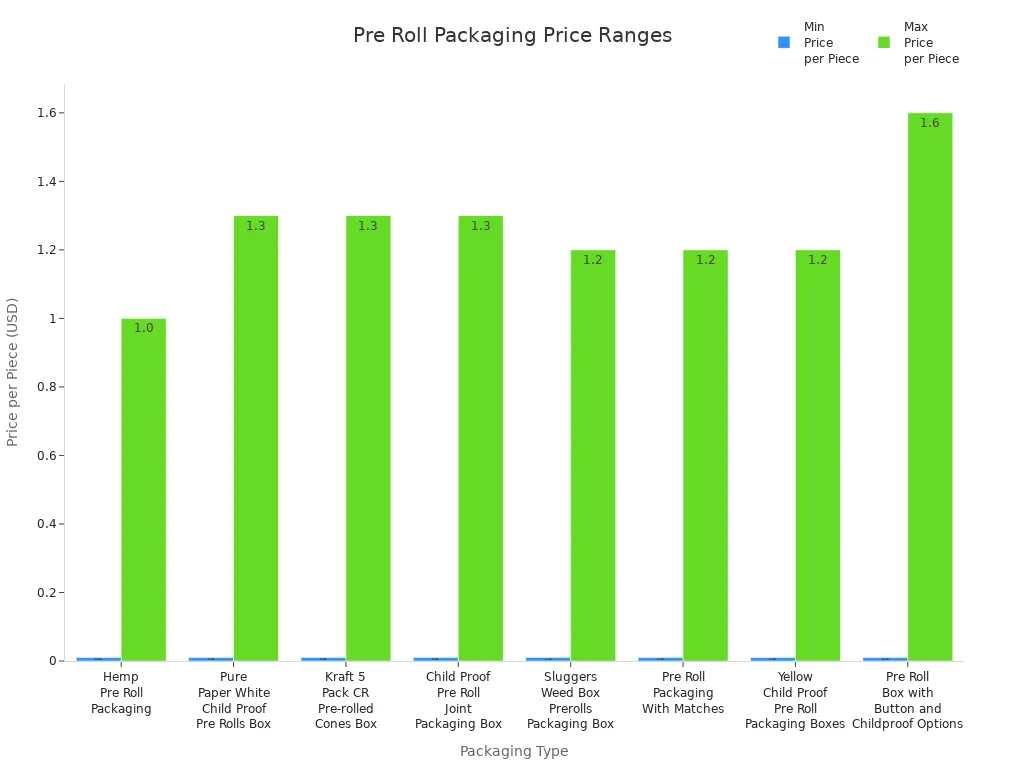

Choosing the right type of pre roll packaging helps brands protect their products and attract customers. Leading cannabis brands use a variety of packaging styles, each with unique features, materials, and benefits. The table below compares some of the most popular options:

Packaging Type | Material | Key Features | Child-Resistance | Eco-Friendly | Additional Features | Price Range (per piece) | Pros Highlights | Cons Highlights |

|---|---|---|---|---|---|---|---|---|

Hemp Pre Roll Packaging | Premium paper | Flip-top lid, durable, moisture protection | No | Yes | Classic box design | $0.01 - $1.00 | Environmentally friendly, affordable | Not waterproof, costly for small orders |

Pure Paper White Child Proof Pre Rolls Box | Paper | Child-proof button, match compartment | Yes | Yes | Multiple sizes, good sealing | $0.01 - $1.30 | Childproof, eco-friendly, bulk discounts | Not waterproof, pressure sensitive |

Kraft 5 Pack CR Pre-rolled Cones Box | Kraft & copper paper | Drawer-style box, paper tray, compartments | Yes (plastic button) | Yes | Label and print customization | $0.01 - $1.30 | Good feel, prevents sliding, customizable | Not waterproof, repeated use damage |

Child Proof Pre Roll Joint Packaging Box | Paper | Magnetic lid, drawer split design, match storage | Yes (EVA button) | Yes | Separate protective covers | $0.01 - $1.30 | Unique magnetic lid, eco-friendly | Not waterproof, slightly cumbersome |

Sluggers Weed Box Prerolls Packaging Box | Not specified | Separate matchbox, tamper-evident seal | Not specified | Yes | Well-designed dual compartments | $0.01 - $1.20 | Tamper-evident, practical design | Limited capacity (3 pre-rolls) |

Pre Roll Packaging With Matches | Recycled kraft | Retro design, match compartment | Not specified | Yes | Customizable logo on flap | $0.01 - $1.20 | Popular retro design, customizable | Not waterproof, limited capacity |

Yellow Child Proof Pre Roll Packaging Boxes | Paper | Two buckles, two-stage pull-out design | Yes | Yes | Hot stamping and laminating for premium feel | $0.01 - $1.20 | Secure closure, premium look | Soft, easily deformed |

Pre Roll Box with Button and Childproof Options | Not specified | Two childproof button types, custom divider inserts | Yes | Yes | Durable, reusable, stylish | $0.01 - $1.60 | Multiple childproof options, customizable inserts | Small orders expensive |

Tubes & Vials

Tubes and vials remain a top choice for pre roll packaging. Brands select from pop-top tubes, glass vials, and cardboard tubes. Each option offers unique advantages:

Tubes provide airtight packaging, which helps maintain freshness.

Glass vials resist chemicals, offer 100% recyclability, and preserve flavor. They also allow customers to see the product.

Cardboard tubes are biodegradable, compostable, and reusable. They offer a large surface for branding and printing.

Plastic vials feature airtight, moisture-resistant, odor-proof, and child-resistant designs. Many use FDA-grade plastic.

Tip: Tubes work well for on-the-go consumers who want portability and discretion.

However, tubes may not always seal as tightly as squeeze-top bottles. This can affect freshness over time. Cardboard tubes may not fit every brand’s style due to their round shape.

Boxes & Tins

Boxes and tins offer brands a range of choices for pre roll packaging. Paper boxes cost less and allow for easy customization. They work well for brands that want lightweight, eco-friendly packaging. However, paper boxes provide limited protection against moisture and crushing.

Tin packaging costs more but delivers strong protection. Tins keep pre rolls fresh and safe from damage. They also give products a premium, elegant look. Tins suit collectible or high-end products best.

Packaging Type | Cost Range | Product Protection | Pros | Cons |

|---|---|---|---|---|

Low to medium | Poor moisture resistance, limited compression | Lightweight, good printing, eco-friendly | Susceptible to deformation | |

Medium to high | Excellent moisture and dust resistance, strong | Durable, crush-resistant, premium look | Higher cost, heavier |

Eco-Friendly Options

Many brands now choose eco-friendly pre roll packaging. These options use recycled paper, kraft, or biodegradable materials. Hemp paper boxes and recycled kraft packaging reduce environmental impact. Cardboard tubes and paper boxes can be compostable and recyclable.

Note: Eco-friendly packaging appeals to customers who care about sustainability and want to reduce waste.

Some eco-friendly options may cost more or offer less water resistance. Brands must balance sustainability with product protection.

Custom Packaging

Custom pre roll packaging helps brands stand out. Cannabis companies often request:

Custom printed boxes, tubes, and multi-packs

Eco-friendly materials like recycled or biodegradable paper

Child-resistant designs for safety and compliance

Unique colors and sizes to match product needs

Finishes such as matte or gloss lamination, spot UV, embossing, foiling, and holographic effects

Features like die cutting, windows, gussets, hang holes, tear notches, and inside printing

Custom packaging allows brands to enhance shelf appeal, protect freshness, and create a memorable experience. It also helps meet legal requirements and strengthens brand identity.

Pre Roll Packaging Features

Child-Resistant

Child-resistant packaging protects children from accidental cannabis exposure. The Poison Prevention Packaging Act of 1970 (PPPA) sets the foundation for these rules in the United States. Packaging must require two different motions to open, such as “Push Down & Turn” or “Squeeze Lock Closures.” States like California, Colorado, and Illinois require child-resistant packaging for all cannabis products. These packages must pass tests to ensure children cannot open them easily, but adults can still access the product. The table below shows how different states apply these rules:

State | Child-Resistant Requirement | Other Rules |

|---|---|---|

California | Yes | No appeal to minors, clear THC/CBD labels |

Colorado | Yes | Opaque, resealable, clear potency labeling |

Oregon | Yes | Focus on sustainability |

Washington | Yes | Batch numbers, serving sizes, expiration |

Nevada | Yes | Tamper-evident, non-transparent, lab results |

Massachusetts | Yes | Readable size and typeface |

Illinois | Yes | Universal cannabis symbol |

Smell-Proof

Smell-proof features help keep cannabis fresh and private. Packaging uses airtight seals, UV-resistant materials, and sometimes activated carbon filters. These features block odors and protect pre rolls from air, moisture, and light. Smell-proof boxes and bags help preserve potency, flavor, and aroma. They also make it easier for users to carry products discreetly. Regular inspection of seals and careful cleaning keep these features working well.

Tip: Smell-proof packaging improves both freshness and privacy for users in public spaces.

Customization

Brands use customization to make their pre roll packaging unique. Suppliers offer many options, such as digital or offset printing, embossing, debossing, and spot UV finishes. Companies can choose from materials like glass, plastic, cardboard, or tins. Custom shapes include cuboid, round, or sleeve-slider designs. Printing can use PMS or CMYK color models for accurate branding. Many suppliers provide design support, 3D mock-ups, and even small order quantities. Customization helps brands stand out and meet both safety and branding needs.

Budget & Sourcing

Cost Factors

Many elements influence the price of packaging for pre-rolls. Brands must consider the following:

Material costs change based on the quality of flower, rolling papers, and filters.

Labor and automation affect expenses. Hand rolling costs more than machine rolling, but machines need oversight.

Infusions and add-ons, such as live resin or kief, increase complexity and price.

Branding and marketing, like premium packaging or endorsements, raise perceived value.

Compliance and regulatory needs, such as child-resistant features and lab testing, add non-negotiable costs.

Retail markup and taxes also impact the final price.

Cost Factor | Description | Example Impact |

|---|---|---|

Labor and Production | Hand vs. machine rolling, quality control, packaging, labeling | Hand rolling is costly; machines need oversight |

Material Costs | Flower, papers, filters, specialty wraps | Flower: $1–10+/g; papers/filters vary |

Infusions and Add-ons | Live resin, wax, kief, flavor additives | Infused pre-rolls cost more |

Branding and Marketing | Premium packaging, endorsements | Raises costs significantly |

Compliance and Regulatory | Lab testing, child-resistant packaging, labeling, taxes | Adds non-negotiable costs |

Bulk & Wholesale

Ordering packaging in bulk helps brands lower per-unit costs. Many companies choose wholesale options to manage expenses, especially during supply chain challenges. Bulk orders also speed up delivery when sourced domestically. However, the savings depend on the packaging type and product size. For example, a fifty-cent package may work for a multi-pack but not for a single pre-roll. Brands must balance cost savings with design, material, and sustainability goals.

Tip: Bulk buying can help brands stay competitive, but careful planning ensures the right fit for each product.

Minimum Orders

Manufacturers set minimum order quantities (MOQs) for different packaging types. These MOQs vary by design and customization level.

Packaging Type | Minimum Order Quantity (MOQ) |

|---|---|

5-Pack Pre-Roll Boxes | |

Custom Pre-Roll Boxes | 1,000 units |

Luxury Pre-Roll Boxes | 500 units |

Digital printing often starts at 1,000 units, while full design personalization may require 5,000 or more. Brands should check MOQs before placing orders to avoid surprises.

Product Integrity

Protection & Freshness

Protecting pre-rolls from damage and preserving freshness are top priorities for any cannabis brand. Packaging must shield products from moisture, light, and air. Airtight seals help keep terpenes and cannabinoids from degrading. Many brands use UV-resistant materials, such as amber or black glass, to block harmful light. Rigid tubes and foam inserts prevent crushing during transport. Some companies add humidity packs or insulated liners to control temperature and moisture. These features work together to keep pre-rolls potent and flavorful.

Key elements that support product integrity and freshness include:

Child-resistant closures that prevent unauthorized access and help maintain freshness.

Tamper-evident seals that give consumers confidence in product safety.

Opaque packaging that reduces light exposure and preserves cannabinoids.

Airtight designs that stop moisture from entering and prevent mold growth.

Odor control features, such as double seals or activated charcoal inserts, that keep products discreet and fresh.

Sustainable packaging options, like compostable tubes or FSC-certified paperboard, also protect products while meeting consumer demand for eco-friendly solutions.

Safety Standards

Safety standards for cannabis packaging protect both consumers and brands. Regulations require child-resistant packaging that children under five cannot open easily. Tamper-evident features, such as shrink bands or induction seals, show if someone has tried to open the package. Clear labeling is essential. Labels must include product name, manufacturer details, batch number, net weight, ingredients, and THC/CBD content. Warning labels inform users about psychoactive effects and the need to keep products away from children.

Other important safety measures include:

Track and trace systems that use unique identifiers to follow products from seed to sale.

Compliance with THC limits, such as the 0.3% threshold for hemp.

Testing for contaminants like heavy metals, as required by some states.

Regular updates to packaging based on changing regulations.

Brands should work with reputable suppliers and consult regulatory experts to ensure all safety standards are met.

Shelf Appeal

Branding

Branding shapes how customers feel about a product before they even pick it up. Companies use color, logo, and finish to create a strong first impression. Color psychology helps set the mood and show brand identity. For example, green often signals natural or eco-friendly products, while gold or metallic finishes suggest luxury. Brands also use unique shapes and textures to make their packaging stand out. Consistent branding across all products builds trust and helps customers remember the brand.

Tip: Shoppers decide if a product fits their needs in just two seconds, so packaging must quickly communicate the right message.

Labeling

Clear and honest labeling guides customers and builds confidence. Labels should use readable fonts and layouts to highlight important details like strain type, potency, and usage instructions. Including legal disclaimers and QR codes adds transparency and helps customers make informed choices. Labels that show product benefits, such as eco-friendly materials or special features, can influence buying decisions.

Labels often include:

Strain name and type

THC/CBD content

Usage instructions

Legal warnings

Market Differentiation

Standing out on crowded shelves requires more than just good looks. Brands use special finishes like embossing, gold foil, or matte textures to catch the eye. Packaging form factors, such as slim tubes or luxury boxes, add convenience and value. Seasonal or limited-edition designs create excitement and encourage repeat purchases.

Effective strategies include:

Practical features like resealable closures

Collectible or co-branded packaging

Clear product information for quick decisions

These elements help brands attract attention, build loyalty, and drive sales in a competitive market.

Feedback & Iteration

Budtender Input

Budtenders play a key role in the feedback process. They interact with customers daily and hear honest opinions about packaging. Many brands build strong relationships with budtenders to gain early insights into what customers like or dislike. Budtenders often notice trends or issues before brands do. Their feedback can highlight problems with opening packages, confusion about labeling, or preferences for certain features. Brands that listen to budtenders can adjust their packaging quickly and stay ahead of competitors.

Tip: Regular meetings with budtenders help brands gather real-time feedback and spot new opportunities for improvement.

Customer Feedback

Customer feedback shapes the future of packaging. Brands use several methods to collect this information:

1. Focus groups allow brands to observe how people interact with packaging and discuss their experiences. 2. Online surveys reach a large audience and provide anonymous feedback, though they may not capture hands-on reactions. 3. Social media polls engage both current and potential customers, offering quick insights into preferences.

Some brands add QR codes to packaging or marketing materials. These codes link customers to surveys or loyalty programs, making it easy to share opinions. Monitoring sales data and online reviews also helps brands spot patterns and identify areas for improvement.

Brands that gather feedback from both budtenders and customers can test new ideas and refine their packaging. They often adjust child-resistant features, update designs, or improve sustainability based on real-world input. This cycle of feedback and iteration keeps packaging relevant and effective.

Brands should select pre roll packaging that protects products, meets regulations, appeals to customers, and fits budgets. The cannabis industry changes quickly, so companies must review packaging whenever new rules or trends appear. Upgrading packaging builds trust, reduces returns, and increases loyalty. Evaluate current packaging and seek feedback for improvement.