Mobile battery packaging protects batteries from pressure, impact, moisture, and static electricity. Manufacturers use anti-static foam inserts, corrugated fiberboard, and paperboard to keep batteries safe.

Clear warnings and proper labeling on packaging help users handle lithium polymer batteries safely.

Visually appealing packaging improves customer satisfaction and supports regulatory compliance.

Key Takeaways

Mobile battery packaging protects batteries from damage, moisture, and electrical faults using strong materials and secure designs.

Manufacturers use different materials and packaging styles based on battery type to ensure safety and improve customer experience.

New safety trends focus on eco-friendly materials, fire-resistant designs, and strict regulations to keep batteries safe and support the environment.

Mobile Battery Packaging

Purpose and Protection

Mobile battery packaging serves as the first line of defense for batteries during shipping, storage, and handling. Its main function is to shield batteries from physical damage, moisture, and static electricity. When batteries travel long distances, they face risks such as impact, vibration, and pressure. Packaging helps prevent these hazards by isolating the battery and keeping it stable.

Mechanical abuse, like squeezing or dropping, can cause cracks or leaks in batteries.

Proper sealing and isolation inside the package reduce the chance of short circuits and electrolyte leakage.

Packaging also keeps battery terminals from touching each other or metal objects, which could lead to dangerous electrical faults.

Note: Battery packaging must maintain stability and safety, especially for lithium-ion batteries, which are sensitive to heat and pressure.

Manufacturers test packaging by simulating real-world abuse, such as shocks, temperature changes, and vibration. These tests help identify weak points and ensure the packaging can handle tough conditions. Certification standards like UN/DOT 38.3 and IEC 62133 guide these tests and help guarantee safe market release.

Materials Used

Manufacturers choose battery packaging material based on the type of battery and its safety needs. Common materials include steel or alloy shells for cylindrical cells, aluminum alloy or stainless steel for prismatic cells, and aluminum-plastic composite film for pouch cells. Each material offers unique benefits and drawbacks.

Battery Type | Packaging Material | Advantages | Disadvantages |

|---|---|---|---|

Cylindrical | Steel or alloy shells | High yield, consistent quality, low cost, good for mass production | Heavy, lower energy density |

Prismatic | Aluminum alloy or stainless steel | Lighter, safer, higher energy density | Less flexible, variable battery life |

Pouch | Aluminum-plastic composite film | Flexible, lightweight, swells instead of exploding, high capacity | High development cost, sensitive to heat and humidity, needs customization |

Other materials, such as cardboard, foam, and PET plastic, play important roles in packaging design. Cardboard provides sturdy protection and is easy to recycle, supporting environmental sustainability. Foam offers cushioning to absorb shocks during transport, while PET plastic is commonly recycled and helps reduce pollution.

Pouch lithium batteries use a three-layer film: an outer protective layer, a middle aluminum foil layer, and an inner high-barrier layer. This design allows the battery to swell and crack safely under stress, rather than explode. However, pouch cells need careful thermal management and are sensitive to humidity.

Battery Packaging Boxes

Battery packaging boxes are essential for safe transport, regulatory compliance, and brand identity. These boxes use strong, rigid materials to withstand drops and impacts. They separate batteries with dividers or individual bags to prevent short circuits. Non-conductive and acid-resistant materials protect against leaks and electrical hazards.

Boxes must secure batteries to prevent movement during transit.

Damaged or recalled batteries require special packaging and handling.

Regulations such as IATA, DOT, and IMDG set strict rules for packaging, labeling, and documentation.

Proper labeling includes hazard warnings, UN numbers, and handling instructions.

Manufacturers follow best practices to meet both safety and branding needs:

Insulate terminals to avoid short circuits.

Use foam or bubble wrap for protection.

Clearly label boxes with battery type, voltage, and hazard warnings.

Include safety data sheets and handling instructions.

Use sturdy, sealed containers.

Employ eco-friendly materials to appeal to environmentally conscious consumers.

Add custom branding elements like logos and colors for a premium look.

Custom battery packaging helps brands stand out and build trust. Clear product information and safety features show a commitment to quality. Easy-to-open designs and leakage protection improve the customer experience. Eco-friendly options also boost brand reputation.

Packaging box designs differ based on battery type. For example, lithium battery packaging uses fireproof pouches, insulated padding, and shockproof casings to manage heat and prevent fires. Nickel-metal hydride batteries focus more on mechanical protection and temperature tolerance.

Packaging Aspect | Lithium-Ion Batteries | Nickel-Metal Hydride (NiMH) Batteries |

|---|---|---|

Sensitivity | Highly sensitive to heat, pressure, and punctures | Less sensitive, focus on high-temperature resistance |

Common Packaging Materials | Fireproof pouches, aluminum shells, plastic casings | Plastic shells, metal casings |

Safety Features | Fire-resistant materials, insulated padding, shockproof casings | Emphasis on durability for repeated charging cycles |

Structural Requirements | Foam inserts, shock-resistant boxes | Durable casings for mechanical protection |

Packaging Focus | Fire resistance and thermal management | Mechanical protection and temperature tolerance |

Consumer vs Industrial | Convenience and branding for consumers; durability and fire resistance for industrial use | Similar focus on durability, less emphasis on fire resistance |

Battery packaging boxes play a vital role in preventing failures during shipping. They protect against poor packing, overcharging, overheating, and cargo shifting. Staff training, proper labeling, and secure packing all help reduce risks. Early detection systems, such as thermal scanners and gas detectors, add extra layers of safety.

Tip: Always check for clear labeling and sturdy construction when choosing battery packaging boxes. These features signal a brand's commitment to safety and quality.

Safety Trends

New Materials

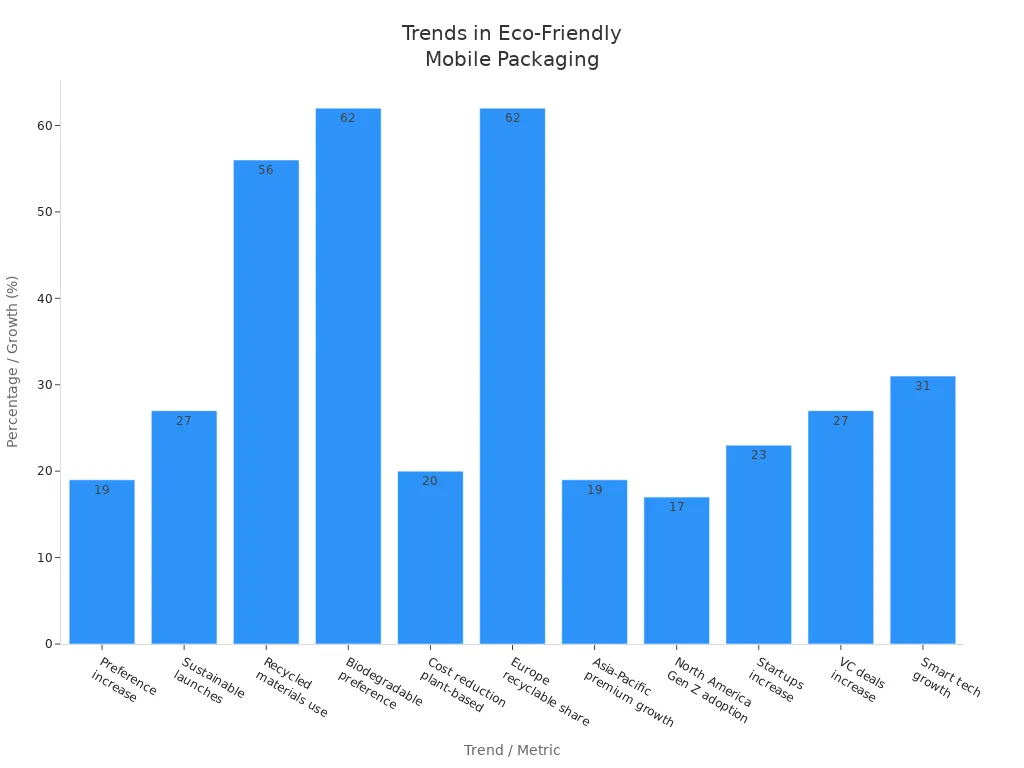

Manufacturers now focus on sustainable packaging solutions to address both safety and environmental concerns. Cardboard and corrugated cardboard dominate the market, holding over 63% and 75% revenue share in battery packaging, respectively, in 2023. These materials offer cost-effective, recyclable, and cushioning properties, making them a preferred eco-friendly material. The shift away from plastic blister packs, which declined by 17% at the end of 2023, highlights the growing demand for plastic-free options. In Europe, 62% of mobile accessory packaging uses recyclable materials, driven by strict legislation. Companies invest heavily in new production lines for sustainable materials, with Smurfit Kappa and Sonoco investing over $200 million combined since 2022.

Reusable plastic packaging also improves safety assurance for lithium-ion batteries. These materials last up to 200 cycles, compared to only 11 cycles for wood, and support a circular economy by being recyclable at end-of-life. Lightweight designs reduce transportation costs and carbon footprint, helping protect the environment.

Design Innovations

Recent design changes in mobile battery packaging focus on both user safety and product reliability. Corrugated fiberboard and anti-static foam inserts provide robust protection and prevent electrostatic discharge, which can damage sensitive battery cells. Thermoformed trays and custom sizing keep batteries secure during shipping, reducing the risk of movement and short-circuit. Many packages now use fire retardant materials and advanced thermal management systems to prevent overheating.

Innovation Aspect | Description | Safety/Reliability Benefit |

|---|---|---|

Corrugated Fiberboard | Strong, tough secondary packaging for large shipments | Robust protection during transit |

Anti-Static Foam Inserts | Cushions batteries and prevents static discharge | Prevents electrostatic damage |

Thermoformed Trays | Custom trays hold batteries firmly | Prevents movement and damage |

Fire Retardant Materials | Materials that resist ignition | Reduces fire risk |

Custom Sizing & Structure | Packaging tailored to battery dimensions | Reduces damage and defect returns |

Manufacturers also use minimalist and lightweight designs to reduce waste and improve recyclability. Smart packaging features, such as QR codes and sensors, provide traceability and recycling information, enhancing consumer engagement and supporting the environment.

Regulations

Regulatory standards shape the design and distribution of mobile battery packaging worldwide. In the United States, UL and CPSC standards require rigorous safety testing, while OSHA and EPA guidelines ensure worker and environmental safety. The European Union’s Battery Regulation 2023/1542 mandates CE marking, QR codes, and detailed labeling for traceability and sustainability. Packaging must display hazard symbols, product information, and recycling instructions. Producers must register and manage battery waste collection and recycling.

Non-compliance can result in severe penalties. For example, the US Department of Transportation may fine up to $50,000 per infraction for improper packaging or labeling of lithium batteries.

International regulations, such as IATA and IMO, require sturdy packaging to prevent short-circuiting and leaks during transport. These rules drive manufacturers to adopt new safety features and sustainable practices, ensuring safe distribution and supporting a cleaner environment.

Understanding battery packaging helps buyers make safer, smarter choices. Experts highlight several important features:

Durable materials and reinforced corners protect batteries.

Tamper-proof seals and secure inserts boost confidence.

Custom designs support branding and fit.

Safety organizations recommend:

Check for recalls before buying.

Choose trusted sources and recycling options.