Telescoping boxes, also known as telescoping box or telescopic box, feature a two-piece, adjustable structure that provides a custom-fit solution for packaging. This telescoping box design is ideal for protecting tall or unusually shaped products, such as golf clubs or TVs, while minimizing waste and reducing shipping costs.

Telescoping boxes, including both telescoping box and telescopic box styles, dominate the non-corrugated segment thanks to their versatility, space efficiency, and sustainability.

Advantages | |

|---|---|

Corrugated cardboard | Strong, recyclable, crush-resistant |

Kraft paper | Durable, widely used |

Rigid paperboard | Customizable, premium appearance |

Key Takeaways

Telescoping boxes adjust in size to fit many product shapes, reducing waste and protecting items during shipping.

Their two-piece design adds strong protection with double walls, making them ideal for fragile or heavy products.

These boxes save space and materials by shipping flat and using recyclable materials, supporting eco-friendly packaging.

Benefits of Telescoping Boxes

Adjustable Size

Telescoping boxes stand out because of their two-piece, sliding design. This feature allows the telescoping box to adjust in height, creating a snug fit for products of many shapes and sizes. Businesses in logistics, retail, e-commerce, and electronics often choose telescoping boxes for their flexibility. These boxes work well for items like tools, electronics, books, framed art, and even luxury gifts.

Logistics companies use telescoping boxes to fit products of different lengths, which reduces packaging waste and saves storage space.

Retailers benefit from improved product presentation and easier inventory management.

E-commerce sellers use telescoping boxes for subscription boxes, sensitive items, and electronics, ensuring a tight fit and better protection.

Telescoping boxes help companies avoid shipping half-empty boxes, which lowers shipping costs and reduces the risk of damage during transit. A custom fit means less movement inside the box, so fragile items stay safe.

Enhanced Protection

The telescoping box design provides reinforced protection for products. The two-piece structure, with a lid that slides over the base, creates double walls at the ends. This design prevents crushing and adds strength, especially when made from thick corrugated cardboard or rigid paperboard.

Feature/Aspect | Description |

|---|---|

Thick, rigid stock increases protection. | |

Two-piece Design | Lid covers base for maximum protection. |

Corrugated Cardboard Layers | Multiple layers add strength and durability, ideal for heavy or fragile items. |

Use by Luxury Brands | Trusted for shipping high-value items like shoes. |

Custom Inserts | Inserts and accessories add extra safety. |

Adjustable Height | Prevents movement and damage during transit. |

Corrugated cardboard telescoping boxes offer superior durability because of their fluted core, which resists compression, punctures, and moisture. Grey board boxes provide good rigidity but less cushioning and moisture resistance. The telescoping box design boosts compression strength, making it suitable for medium-to-large and sensitive products.

Space and Material Savings

Telescoping boxes help businesses save space and materials in several ways:

The boxes ship flat, which reduces storage and shipping space needs.

The adjustable design means less need for extra packing material, as the box can fit the product closely.

Telescoping boxes are easy to assemble and fold, speeding up the packing process.

Made from recyclable materials, these boxes support sustainable packaging and can be reused.

Folding and collapsible telescoping boxes can reduce return transport volume by up to 75%, allowing more boxes per truckload and lowering CO2 emissions. Using recycled materials also saves energy and reduces environmental impact.

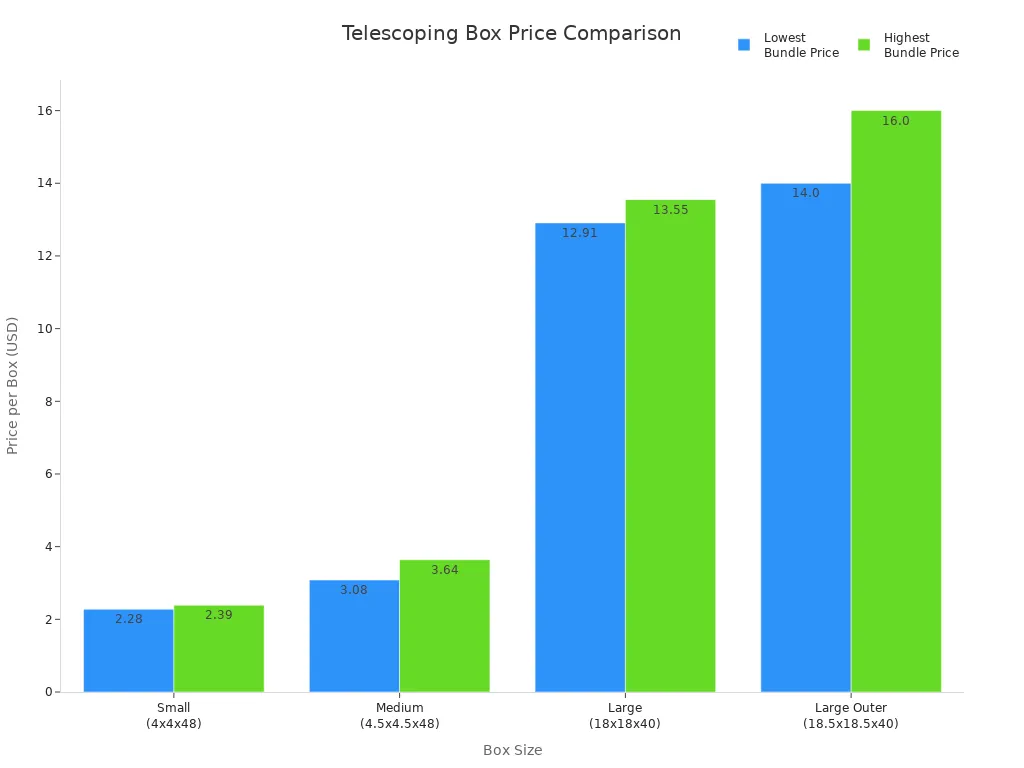

Telescoping boxes come in many sizes, with popular options like 6x4x4 inches, but most businesses order custom sizes to fit their products. This flexibility, combined with the ability to ship flat and use less material, makes telescoping boxes a smart choice for packaging and shipping.

Types and Customization

Telescoping Box Styles

Telescoping boxes come in several styles, each designed for specific packaging needs. The most common type is the full telescope design, where the lid completely covers the base. This style offers strong side-wall protection and works well for heavy-duty shipping or luxury packaging. Partial telescope boxes have lids that only cover part of the base, making them easy to open and close. These are often used for shoes, printer paper, or products that need frequent access.

Box Style | Description | Typical Uses |

|---|---|---|

Full Telescope Design Boxes | Lid fully covers the base for extra strength. | Framed art, electronics, luxury goods |

Lid covers part of the base, easy to open. | Shoes, office supplies, retail items | |

Double Cover Boxes | Trays on both ends for bulky or heavy items. | Appliances, furniture, machinery |

Full Telescope Half Slotted | Two half slotted containers joined together, quick to assemble. | Fresh produce, affordable packaging |

Interlocking Double Cover | Added flanges for security, often banded. | Large or hazardous products |

Some telescoping box designs can expand up to three times their original height, making them suitable for products with changing dimensions or unique shipping requirements.

Custom Fit Solution

A telescoping box can be tailored to fit almost any product. Businesses choose custom sizes, materials, and inserts to protect fragile or irregular items. Strong materials like corrugated cardboard or rigid stock provide extra durability. Custom-fit inserts, such as foam or molded trays, keep products secure and reduce movement during transit. This snug fit helps prevent damage and increases customer satisfaction. Custom dimensions also simplify inventory management and ensure products arrive safely.

Custom-fit telescoping boxes support a wide range of industries, from electronics to luxury goods, by meeting specific shipping requirements and protecting valuable items.

Branding Options

Branding plays a key role in packaging. Companies often request custom graphics, logos, and finishes to make their telescoping box stand out. Popular options include full-color printing, foil stamping, embossing, and die-cut windows. Smooth box surfaces allow for clear branding and product information. Many suppliers offer premium finishes like matte or gloss lamination, soft-touch coatings, and pearlescent effects. These features not only enhance appearance but also add a layer of protection.

Industries such as apparel, cosmetics, electronics, and luxury brands use custom branding to boost product appeal and recognition.

Custom inserts, labels, and tapes further personalize the packaging experience.

Telescoping boxes deliver unique benefits for packaging.

Their adjustable design fits large or irregular items, offering strong protection and space savings.

Businesses report fewer shipping damages and higher sales with custom options.

Versatile styles and branding choices make them a smart solution for many industries.