Corrugated boxes serve as a backbone for packaging in global logistics. Their unique structure, made from multiple layers of kraft paper with a fluted core, provides strong cushioning and impact resistance. Businesses across industries rely on these boxes for safe shipping, as shown by a market size reaching USD 171.45 billion in 2024 and projected growth to over USD 321.9 billion by 2032.

Key Takeaways

Corrugated boxes have a strong, layered design that protects products during shipping and storage.

Different box types like single, double, and triple wall offer varying strength for light to heavy items.

Flute grades affect cushioning and print quality, helping businesses choose the right protection and branding.

Corrugated boxes are widely used in shipping, retail, e-commerce, and food industries for their durability and customization.

These boxes provide cost savings by reducing damage, lowering shipping weight, and improving supply chain efficiency.

Sustainability is a major benefit, as corrugated boxes use recycled materials and are highly recyclable.

Custom sizes, printing, and special features let companies create packaging that fits products and boosts brand appeal.

Corrugated Boxes Overview

Definition

Corrugated boxes are packaging containers made from corrugated cardboard. Manufacturers create these boxes by combining three layers of kraft paper: two flat linerboards and a wavy, fluted medium sandwiched between them. This construction gives the boxes their signature strength and cushioning. Businesses use corrugated boxes to ship, store, and protect a wide range of products. Their design allows for easy customization, making them suitable for many industries, including food, electronics, and retail.

Structure

The structure of corrugated boxes sets them apart from regular cardboard packaging. Each box features:

Linerboards: These flat sheets form the outer surfaces and provide rigidity.

Fluted Medium: The wavy layer in the middle acts as a shock absorber, protecting contents from impacts.

Multiple Walls: Some boxes use single, double, or even triple layers of fluting and linerboards to increase strength.

Tip: The combination of liners and fluting determines the box’s durability and protective qualities.

This layered design helps the box resist bending and crushing. It also allows the box to remain lightweight while offering strong protection.

Importance

Corrugated boxes play a vital role in modern packaging and logistics. Their importance comes from several factors:

Statistic/Insight | Details |

|---|---|

Market Value | Projected to reach $212.3 billion by 2034 |

Usage in E-commerce | Over 70% of direct-to-consumer companies use corrugated boxes for last-mile delivery |

Key Advantages | Cost-effectiveness, reusability, recyclability, customization |

Innovations | Water-resistant coatings, RFID integration, automation compatibility |

Industry Applications | Warehousing, e-commerce, retail, manufacturing |

Sustainability Trends | Use of recycled materials, biodegradable coatings, digital printing |

The rise of e-commerce has increased demand for packaging that is both durable and cost-effective. Corrugated boxes meet these needs by offering protection, lightweight construction, and easy recyclability. Companies also value their ability to customize boxes for branding and product fit. Sustainability initiatives drive further innovation, with manufacturers adopting recycled materials and biodegradable coatings.

Corrugated boxes support efficient shipping and storage.

They help companies meet environmental goals.

Their versatility allows use across many industries.

These factors make corrugated boxes a cornerstone of efficient, modern packaging solutions.

Materials and Construction

Fiberboard Layers

Corrugated boxes use fiberboard layers to achieve strength and durability. Manufacturers design these layers in several configurations to meet different packaging needs:

Single Wall: This type features one fluted layer sandwiched between two liners. It is the most common construction and works well for everyday shipping.

Double Wall: Two fluted mediums are separated by an additional liner. This structure increases strength and is ideal for heavier or more fragile items.

Triple Wall: Three fluted layers, each separated by liners, provide maximum protection. Triple wall boxes can support very heavy loads and withstand rough handling.

Each configuration uses different flute profiles, such as A, B, C, E, and F, to balance cushioning and compression strength. The choice of fiberboard layer depends on the product’s weight, fragility, and shipping conditions.

Liners and Fluting

The liners and fluting form the core of corrugated box construction. Liners are flat sheets that cover the outside and inside surfaces of the box. Fluting is the wavy paper layer placed between the liners. Together, they create a structure that resists bending and absorbs impacts.

Manufacturers select from several types of paper for liners:

Kraft Paper: Made by removing lignin from wood pulp, kraft paper offers high strength and tear resistance.

Bleached White Kraft: This paper undergoes a bleaching process for extra whiteness and strength, making it suitable for premium packaging.

Test Liners: These liners use recycled content and come in different grades for varying strength needs.

Chip Liners: Made from lower-quality recycled paper, chip liners are cost-effective for less demanding applications.

For fluting, options include semi-chemical flutes, which use hardwood pulp for density and compression strength, and waste-based flutes, which use 100% recycled paper. These choices support both performance and sustainability goals.

Note: The combination of liner and flute materials affects the box’s durability, print quality, and environmental impact.

Manufacturing Process

The manufacturing process for corrugated boxes involves several precise steps:

Stock Preparation: Workers prepare raw materials by pulping, cleaning, refining, and blending fibers.

Corrugating: Machines form the fluted medium by passing paper through heated corrugating rolls.

Gluing: Starch-based adhesives bond the liners to the fluted medium, creating a strong sandwich structure.

Cutting and Creasing: Equipment cuts the sheets to size and scores fold lines for easy assembly.

Printing and Die Cutting: Graphics and branding are printed, and box blanks are cut to shape.

Folding and Gluing: The box blanks are folded and sealed with adhesive.

Bundling and Shipping: Finished boxes are stacked, bundled, and prepared for delivery.

Quality control measures, such as the Mullen Burst Test and Edge Crush Test, ensure that each box meets industry standards for strength and durability. Manufacturers may also apply coatings for water resistance, electrostatic protection, or enhanced branding. Compliance with standards from organizations like ASTM and the Global Recycled Standard ensures technical excellence and regulatory approval.

Types

Single Wall

Single wall corrugated boxes represent the most common type used in packaging. Manufacturers construct these boxes with three layers: an outer liner, a fluted medium, and an inner liner. This design provides moderate strength and protection for everyday shipping needs.

The performance of single wall boxes depends on two main tests. The Edge Crush Test (ECT) measures how much weight a box can withstand when stacked. A typical single wall box with a 32 ECT rating supports up to 40 pounds, making it suitable for lighter products and shipments with minimal stacking. The Bursting Test, also known as the Mullen Test, measures resistance to puncture or rupture. Most single wall boxes have a 200# Bursting Test rating, which indicates good durability against rough handling.

Box Type | Bursting Test (lbs) | Edge Crush Test (ECT) | Approximate Max Load (lbs) |

|---|---|---|---|

Standard Single Wall | 200# | 32 ECT | 40 |

Heavy Duty Single Wall | 275# | 44 ECT | 65 |

Note: Single wall corrugated boxes work best for retail packaging, lightweight shipping, and products that do not require heavy stacking.

Double Wall

Double wall corrugated boxes offer greater strength and durability than single wall options. These boxes feature two fluted mediums separated by three linerboards. This construction increases stability and load-bearing capacity.

Double wall boxes excel in protecting heavier, fragile, or valuable items during shipping and storage. The extra layer of fluting provides enhanced resistance to crushing, punctures, and impacts. Industries often use double wall boxes for long-distance transit, stacking, and situations where extra protection is necessary.

Feature | Single Wall Box | Double Wall Box |

|---|---|---|

Construction | One fluted layer between two liners | Two fluted layers and three liner sheets |

Strength | Moderate | High |

Durability | Good | Excellent |

Weight Capacity | Lower | Higher |

Protection | Suitable for lightweight, non-fragile | Ideal for heavy, fragile, or valuable items |

Cost | Lower | Higher |

Common Uses | Retail packaging, lightweight shipping | Shipping heavy items, long-distance transit, stacking, extra protection needed |

Double wall corrugated boxes provide a reliable solution for businesses that need to ship products with higher weight or value. The added strength helps prevent damage and ensures safe delivery.

Triple Wall

Triple wall corrugated boxes deliver the highest level of strength and protection available in fiberboard packaging. These boxes contain three fluted mediums and four linerboards, creating a robust structure that withstands extreme conditions.

Triple wall construction offers exceptional resistance to impact, compression, and environmental factors.

The design improves cushioning, puncture resistance, and stacking strength.

Industries such as aerospace, defense, medical, and electronics rely on triple wall boxes for shipping sensitive or heavy equipment.

Common formats include Gaylord boxes, hybrid containers, and tray-sleeve-lid systems.

These boxes help reduce damage rates and improve return on investment by protecting valuable goods during transport.

Technical performance tests, such as the Edge Crush Test, Flat Crush Test, and Mullen Burst Test, confirm the superior durability and load capacity of triple wall corrugated boxes. These tests ensure that the boxes meet strict quality standards for protection and reliability.

Tip: Triple wall boxes are the preferred choice for high-performance applications where maximum protection is essential.

Single Face

Single face corrugated boxes feature a simple yet effective construction. Manufacturers create these boxes by attaching a single fluted medium to one flat linerboard. This design leaves one side of the fluting exposed, while the other side remains covered by the liner. The result is a flexible and lightweight material that adapts to various packaging needs.

Key Features of Single Face Corrugated Boxes:

One linerboard and one fluted medium

Exposed fluting on one side

Lightweight and flexible

Easy to wrap around irregular shapes

Single face corrugated boxes serve as protective wraps, pads, or inserts rather than standalone shipping containers. Companies often use them to cushion fragile items, line shipping cartons, or separate products within a box. The exposed fluting provides shock absorption and prevents scratches during transit.

Note: Single face corrugated material works well for packaging electronics, glassware, and other delicate goods that require extra padding.

Empirical studies highlight the effectiveness of single face corrugated boxes in specific packaging applications. Experimental tests, such as the Edge Crush Test (ECT) and Box Compression Test (BCT), show that single face corrugated boxes with micro-wave E-type structures deliver sufficient compressive strength for lightweight items like electronics and clothing. These tests also reveal that using single face corrugated material reduces overall material usage and shipping costs. Numerical simulations using finite element modeling confirm the mechanical behavior and stacking performance of these boxes. Researchers use McKee’s empirical formula to predict the compressive strength of single face corrugated boxes, further supporting their reliability in packaging.

Laboratory tests on single face corrugated boxes with B flute demonstrate their structural integrity. Technicians condition the boxes under standard laboratory settings and use high-precision press machines to measure compressive strength. Multiple box geometries undergo testing with several samples to ensure consistent results. These findings confirm that single face corrugated boxes provide dependable protection for lightweight goods.

Application Area | Benefit | Example Use Cases |

|---|---|---|

Cushioning | Absorbs shocks and prevents scratches | Electronics, glassware |

Wrapping | Flexible for irregular shapes | Furniture, automotive parts |

Interleaving | Separates products within a box | Bottles, ceramics |

Padding | Adds extra protection in cartons | Clothing, books |

Single face corrugated boxes offer a cost-effective and adaptable solution for businesses seeking to enhance product protection without adding significant weight or bulk. Their unique structure makes them a valuable component in modern packaging strategies.

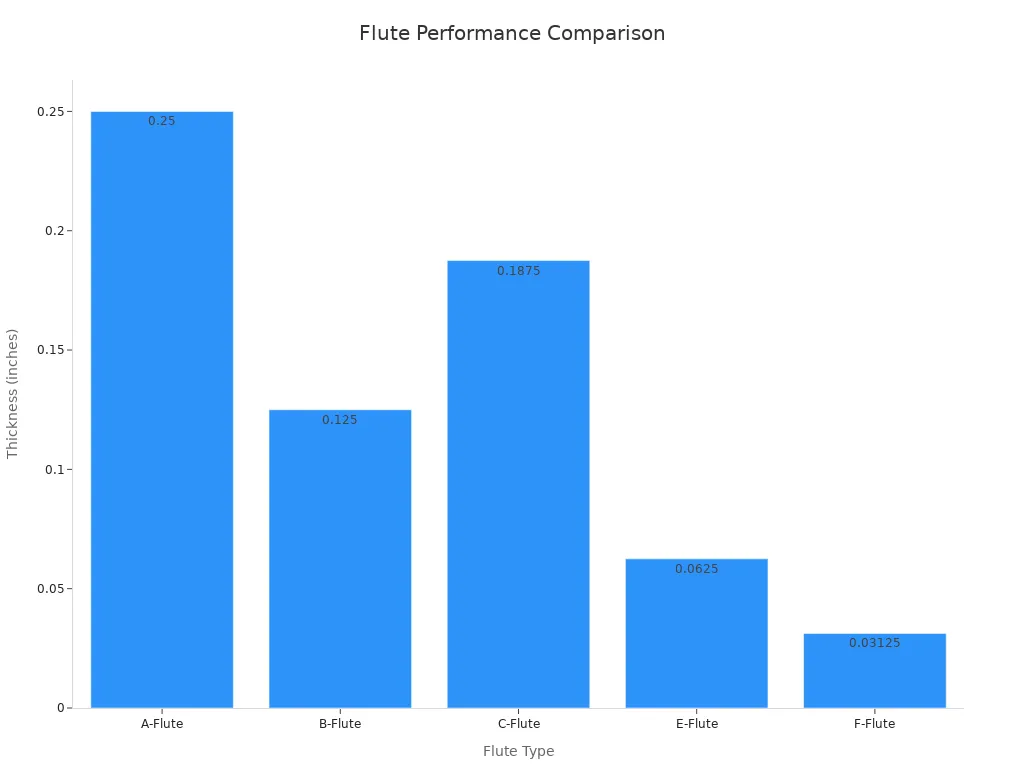

Flute Grades

Corrugated boxes use different flute grades to achieve specific performance characteristics. Flutes refer to the wavy layer sandwiched between linerboards. The size and shape of these flutes affect the box’s strength, cushioning, and printability. Manufacturers select flute grades based on the product’s protection needs and the desired appearance of the packaging.

Below is a comparison of the most common flute types:

Flute Type | Thickness (inches) | Key Performance Characteristics |

|---|---|---|

A-Flute | 1/4 | Largest flute size; highest cushioning and protection; excellent compression and stacking strength; ideal for fragile items |

B-Flute | 1/8 | Thinner flute; strong puncture and crush resistance; good all-around performance; flatter surface for better printing and die-cutting |

C-Flute | 3/16 | Versatile; flexible; average crush resistance and stacking strength; common for shipping boxes and packing fragile goods |

E-Flute | 1/16 | Thinner than C; excellent compression and crush resistance; relatively flat surface for high-quality printing; used for small, delicate products |

F-Flute | 1/32 | Thinnest; similar protection to E-Flute; very smooth surface for premium printing; used in specialty and retail packaging |

A-Flute

A-Flute stands out as the thickest and most protective flute grade. It measures about 1/4 inch in thickness. This large flute size creates deep air pockets, which provide excellent cushioning and shock absorption. A-Flute boxes offer the highest level of compression and stacking strength among all flute types.

Manufacturers often choose A-Flute for packaging fragile or heavy items. The extra thickness helps absorb impacts during shipping and handling. Industries such as electronics, glassware, and ceramics rely on A-Flute boxes to prevent damage. The structure also supports heavy stacking in warehouses.

Tip: A-Flute works best when maximum protection and cushioning are top priorities.

B-Flute

B-Flute features a thinner profile, measuring about 1/8 inch thick. This flute grade delivers strong puncture and crush resistance. The smaller flutes create a flatter surface, which improves print quality and makes die-cutting easier.

B-Flute boxes serve well for packaging canned goods, retail products, and items that need a balance of strength and appearance. The design resists external pressure and protects contents from sharp objects. Many manufacturers use B-Flute for custom-printed boxes because the smooth surface supports detailed graphics.

B-Flute combines durability with versatility.

It suits both protective and display packaging.

C-Flute

C-Flute offers a middle ground between A and B flutes. It measures about 3/16 inch in thickness. C-Flute provides good cushioning, average crush resistance, and reliable stacking strength. This flute grade adapts to a wide range of packaging needs.

Most shipping boxes use C-Flute because it balances protection and flexibility. The structure handles both lightweight and moderately heavy items. C-Flute also works well for packing fragile goods, such as glass bottles and electronics, while keeping the box lightweight.

Note: C-Flute remains the most popular choice for general-purpose corrugated boxes due to its versatility and dependable performance.

E-Flute

E-Flute stands out as one of the thinnest flute grades used in corrugated boxes. It measures about 1/16 inch in thickness. This slim profile allows manufacturers to create boxes that are both lightweight and strong. E-Flute boxes offer excellent crush resistance and a smooth surface for high-quality printing.

Many industries choose E-Flute for packaging small, delicate products. Electronics, cosmetics, and retail items often arrive in E-Flute boxes. The thin fluting provides enough protection for light items while keeping the packaging compact. E-Flute also supports detailed graphics and branding because of its flat surface.

Key Features of E-Flute:

Thickness: Approximately 1/16 inch

High crush resistance

Smooth surface for printing

Lightweight and space-saving

Suitable for die-cutting and custom shapes

Note: E-Flute boxes help companies reduce shipping costs. The thin material takes up less space, which means more boxes fit on a pallet or in a delivery truck.

E-Flute works well for point-of-purchase displays and retail packaging. The boxes look professional and protect products from minor impacts. Many businesses use E-Flute for subscription boxes, gift boxes, and presentation packaging. The flute’s structure also allows for easy folding and assembly.

Application Area | Benefit | Example Use Cases |

|---|---|---|

Retail Packaging | High-quality print surface | Cosmetics, electronics |

Gift and Subscription | Lightweight, attractive design | Gift sets, monthly boxes |

Displays | Easy die-cutting | POP displays |

E-Flute combines strength, printability, and efficiency. It remains a popular choice for brands that want both protection and visual appeal.

F-Flute

F-Flute represents the finest and thinnest flute grade available in corrugated packaging. It measures about 1/32 inch in thickness. This ultra-thin profile creates a very smooth surface, which is ideal for premium printing and intricate designs.

Manufacturers use F-Flute for specialty packaging where appearance matters. Luxury goods, cosmetics, and high-end retail products often come in F-Flute boxes. The fine fluting allows for sharp graphics and vibrant colors. F-Flute also supports detailed embossing and foil stamping.

Advantages of F-Flute:

Ultra-thin (about 1/32 inch)

Superior print quality

Lightweight and compact

Excellent for custom shapes and small boxes

Enhances product presentation

Tip: F-Flute boxes help brands stand out on store shelves. The smooth surface makes logos and artwork look crisp and professional.

F-Flute works best for packaging that needs to impress customers. It protects light items from scratches and minor bumps. Many companies use F-Flute for retail displays, cosmetic packaging, and promotional kits. The flute’s structure also allows for creative box shapes and unique opening mechanisms.

Use Case | Benefit |

|---|---|

Luxury Packaging | Premium look and feel |

Retail Displays | Supports detailed graphics |

Promotional Packaging | Custom shapes and finishes |

F-Flute offers a balance of elegance and protection. It helps businesses deliver products that look as good as they perform.

Box Styles

Regular Slotted

The Regular Slotted Container (RSC) stands as the most widely used corrugated box style in packaging. Manufacturers design RSC boxes with four flaps on the top and bottom that meet in the center when closed. This simple structure allows for efficient production and easy assembly. Businesses choose RSC boxes for their adaptability and cost-effectiveness.

RSC boxes work well for shipping a wide range of products. Their design supports stacking and protects contents during transit. Companies can use these boxes for e-commerce, retail, and industrial applications. The flat supply of RSC boxes saves space in storage and reduces shipping costs. Workers can quickly assemble them on-site, which improves operational efficiency.

Tip: RSC boxes offer a blank canvas for branding. High-impact graphics and premium finishes can enhance shelf presence and attract customers.

Half-Slotted

Half-Slotted Containers (HSC) share a similar design with RSC boxes but feature only one set of flaps, leaving one side open. This open end makes loading and unloading large or heavy items much easier. HSC boxes often serve as trays or covers for products that require frequent access.

Businesses use HSC boxes for items like appliances, furniture, and bulk goods. The open side allows for quick placement on pallets and easy removal of products. HSC boxes also pair well with separate lids or covers for added protection. Their versatility supports use in warehousing, shipping, and retail displays.

HSC boxes provide:

Easy access for oversized or heavy products

Efficient palletization for transport

Compatibility with custom inserts or protective pads

Full Overlap

Full Overlap Containers (FOL) feature flaps that completely overlap each other when closed. This design creates double-thick layers on the top and bottom of the box, offering extra strength and durability. FOL boxes excel at protecting heavy, fragile, or high-value items during shipping.

The overlapping flaps reinforce the box structure, making it ideal for stacking and withstanding rough handling. Industries often use FOL boxes for products that need maximum protection, such as electronics, glassware, or industrial parts.

Box Style | Description | Efficiency and Versatility Highlights |

|---|---|---|

RSC | Four flaps meet in the center; most common style | Adaptable, cost-effective, easy to assemble |

HSC | One open side for easy loading/unloading | Pallet-friendly, ideal for large/heavy items |

FOL | Flaps fully overlap for extra strength | Superior protection for heavy or fragile products |

Corrugated box styles like RSC, HSC, and FOL demonstrate the versatility and efficiency of paperboard packaging. Their tailored designs support a variety of products and industries, while operational benefits such as flat supply and on-site assembly help businesses save time and resources. These styles also allow for customization in size, printing, and finishes, making them a smart choice for both protection and branding.

Die-Cut

Die-cut corrugated boxes offer a high level of customization for packaging needs. Manufacturers use precision cutting tools, called dies, to create boxes with unique shapes, sizes, and features. This process allows for intricate designs that standard box styles cannot achieve. Die-cut boxes often include custom slots, handles, windows, or locking tabs.

Businesses choose die-cut boxes when they need packaging that fits a product exactly. These boxes reduce movement inside the package, which helps protect fragile or oddly shaped items. Die-cutting also supports creative branding. Companies can request boxes with special openings, printed logos, or display windows that showcase the product inside.

Key Features of Die-Cut Corrugated Boxes:

Custom shapes and sizes

Built-in handles or display windows

Locking tabs for secure closure

Easy assembly with pre-scored folds

Enhanced branding options

Tip: Die-cut boxes work well for retail packaging, promotional kits, and subscription boxes. They help products stand out on store shelves.

Manufacturers use computer-aided design (CAD) software to create precise templates for die-cut boxes. This technology ensures that each box matches the product’s dimensions and requirements. The die-cutting process also allows for quick changes in design, which helps businesses respond to new trends or seasonal promotions.

Die-cut corrugated boxes support a wide range of industries. Electronics companies use them for protective inserts. Food brands use them for attractive bakery boxes. Retailers rely on die-cut boxes for gift packaging and point-of-purchase displays.

Application Area | Benefit | Example Use Cases |

|---|---|---|

Retail Packaging | Custom fit and branding | Cosmetics, electronics |

Food Packaging | Hygiene and presentation | Pastry boxes, meal kits |

Promotional Kits | Unique shapes and inserts | Gift sets, sample packs |

E-commerce | Secure shipping and unboxing | Subscription boxes |

Die-cut boxes combine function and style. They protect products while enhancing the customer experience. Many businesses see increased brand recognition and customer satisfaction when they use custom die-cut packaging.

Uses

Shipping

Corrugated boxes play a central role in global shipping. Their layered construction absorbs shocks and resists crushing, which helps protect products during long journeys. Shipping companies rely on these boxes to move goods safely across cities, countries, and continents. The fluted design inside each box acts as a cushion, reducing the risk of damage from impacts or stacking pressure.

Many industries choose corrugated boxes for shipping because they are lightweight yet strong. This combination lowers transportation costs and allows for easier handling. Warehouses and distribution centers stack these boxes efficiently, maximizing storage space. Corrugated boxes also come in various sizes and strengths, making them suitable for everything from small electronics to heavy machinery.

Innovations in box manufacturing have improved durability. For example, new machines can create boxes that resist crushing, which increases reliability during shipping. Companies now trust corrugated packaging for high-value and fragile items, knowing that the boxes will maintain their shape and protect contents until delivery.

Retail

Retailers use corrugated boxes for both storage and display. These boxes help organize products in backrooms and on store shelves. Their customizable design allows retailers to choose boxes that fit specific products, reducing wasted space and improving presentation.

Corrugated boxes support branding efforts. Stores often print logos, product information, or promotional graphics directly on the box surface. This turns ordinary packaging into a marketing tool that attracts customers and communicates brand values. Retailers also benefit from the recyclability of corrugated boxes, which aligns with growing consumer demand for sustainable practices.

The retail sector values the strength and versatility of corrugated packaging. Boxes protect goods from damage during stocking and handling. They also make restocking faster and more efficient, as workers can quickly assemble or break down boxes as needed.

E-commerce

E-commerce companies depend on corrugated boxes to deliver products to customers’ doors. The rise of online shopping has fueled demand for packaging that can withstand frequent handling and long-distance shipping. Corrugated boxes meet these needs by offering protection, lightweight construction, and easy customization.

In the United States, e-commerce accounted for nearly 16% of retail sales in early 2024. This growth has increased the volume of parcels shipped daily. Corrugated boxes ensure that items arrive intact, even after passing through multiple distribution centers. Companies like DS Smith have developed fully recyclable e-commerce packaging, eliminating the need for plastic padding and supporting environmental goals.

E-commerce brands often use custom-printed corrugated boxes to enhance the unboxing experience. Attractive packaging creates a positive first impression and encourages repeat business. The flexibility of corrugated material allows for unique shapes and sizes, which helps companies accommodate a wide range of products, from clothing to electronics.

Tip: Corrugated boxes help e-commerce businesses balance protection, cost, and sustainability, making them a preferred choice for online order fulfillment.

Food and Beverage

Corrugated boxes play a vital role in the food and beverage industry. Companies use these boxes to transport, store, and display a wide range of products, from fresh produce to bottled drinks. The unique structure of corrugated boxes helps protect food items from damage during shipping and handling.

Manufacturers design food-grade corrugated boxes to meet strict hygiene standards. These boxes often use virgin kraft paper liners, which reduce the risk of contamination. Some boxes include special coatings or liners that resist moisture and grease. This feature keeps food fresh and prevents leaks.

Key Uses in Food and Beverage:

Fresh Produce: Growers pack fruits and vegetables in ventilated corrugated boxes. The fluted design allows air to circulate, which helps maintain freshness.

Beverages: Bottled drinks, such as water, soda, and juice, travel safely in sturdy double wall or triple wall corrugated boxes. These boxes prevent breakage and absorb shocks.

Bakery and Confectionery: Bakeries use custom die-cut corrugated boxes for cakes, pastries, and chocolates. The boxes protect delicate items and support attractive presentation.

Frozen and Refrigerated Foods: Some corrugated boxes feature water-resistant coatings. These boxes perform well in cold storage and resist condensation.

Tip: Corrugated boxes with custom inserts keep bottles and jars separated. This design reduces the risk of breakage during transport.

Food and beverage companies value corrugated boxes for their sustainability. Many boxes use recycled fibers and remain fully recyclable after use. This practice supports eco-friendly packaging goals and appeals to environmentally conscious consumers.

Application Area | Corrugated Box Feature | Example Product |

|---|---|---|

Fresh Produce | Ventilated, moisture-resistant | Apples, lettuce |

Bottled Beverages | Double/triple wall, inserts | Wine, soda, juice |

Bakery Goods | Custom die-cut, food-safe | Cakes, pastries |

Frozen Foods | Water-resistant coating | Ice cream, seafood |

Corrugated boxes also support branding in the food sector. Companies print logos, product details, and promotional messages directly on the box. This approach turns packaging into a marketing tool and enhances shelf appeal.

Food safety remains a top priority. Corrugated boxes undergo rigorous testing to ensure they meet food contact regulations. Manufacturers follow guidelines from organizations such as the FDA and the International Safe Transit Association (ISTA).

Corrugated packaging helps food and beverage businesses deliver products safely, maintain quality, and promote their brands. The versatility and protective qualities of these boxes make them a trusted choice across the industry.

Benefits

Protection

Corrugated boxes deliver outstanding protection for products during shipping and storage. Their unique structure, which includes fluted layers sandwiched between linerboards, absorbs shocks and resists crushing forces. This design helps prevent damage from drops, impacts, and stacking pressure. The Box Compression Test (BCT) measures how much weight a box can withstand before collapsing, and results show that compression strength closely matches the strength of the linerboards used. Experimental studies confirm that these boxes shield contents from mechanical hazards such as vibration and compression loads. For example, vibration analysis identifies certain frequency ranges where cushioning materials inside corrugated boxes reduce the risk of damage to fresh produce. The way boxes are designed and stacked also affects their ability to resist loads and maintain their shape under stress. These protective qualities help reduce product losses, especially for fragile goods, and ensure items arrive safely at their destination.

Note: Proper packaging with corrugated boxes can significantly lower the risk of damage during transport, especially for delicate or perishable items.

Durability

Durability stands as a key advantage of corrugated boxes. Manufacturers engineer these boxes with different flute and wall thickness combinations to enhance strength and support repeated use. The reusable corrugated boxes market in North America and Europe reached nearly USD 3 billion in 2022, with strong growth expected through 2030. This trend highlights the confidence industries place in the long-term performance of these boxes. Slotted-type corrugated boxes meet strict edge crush and burst resistance standards, which increases their loading capacity and makes them suitable for multiple reuse cycles. Industries such as food and beverage, as well as e-commerce, rely on these boxes for repeated packaging and transport. Companies like Amazon and Samsung have adopted reusable corrugated boxes in their supply chains, reflecting trust in their durability. According to industry data, corrugated packaging accounted for up to 80% of transported products in Europe in 2022, showing widespread reliance on their strength and repeated usability.

Corrugated boxes withstand repeated handling and transport.

They maintain their shape and protective qualities over multiple uses.

Major industries depend on their durability for efficient logistics.

Cost Efficiency

Corrugated boxes offer significant cost efficiency for businesses across many sectors. Even as raw material, energy, and labor costs rise, the industry continues to improve efficiency and maintain competitive pricing. Economic analyses show that tools like the Full Disclosure software allow companies to compare the total costs of corrugated containers with alternatives, such as reusable plastic crates. These comparisons often reveal that corrugated packaging provides lower overall costs, especially when considering supply chain efficiency and modularity. Case studies in produce and meat supply chains demonstrate that corrugated packaging helps maximize efficiency and minimize expenses. The Corrugated Common Footprint (CCF) standard, for example, optimizes container size and stability, further reducing costs. Companies in the fast-moving consumer goods sector have reported annual savings of millions of dollars by optimizing their packaging strategies with corrugated boxes. These savings come from reduced material usage, improved stacking, and streamlined logistics.

Tip: Choosing the right corrugated box design can help businesses lower shipping costs and improve supply chain performance.

Sustainability

Sustainability stands as a core benefit of corrugated boxes. Manufacturers design these boxes with the environment in mind, using renewable resources and recycled materials. Most corrugated packaging comes from certified forests, which helps reduce deforestation and supports responsible land management. Companies also increase the recycled content in their products, following strict environmental regulations that promote sustainable sourcing.

Modern production methods focus on reducing greenhouse gas emissions. Factories use cleaner technologies and energy-efficient processes to lower their carbon footprint. Waste management practices encourage recycling and reuse, supporting a circular economy. These efforts help minimize waste and keep materials in use for as long as possible.

The Sustainable Packaging Coalition reports that corrugated fiberboard can be reused up to 10 times before losing its strength. This high level of reusability sets it apart from many other packaging materials.

Corrugated boxes lead the industry in recyclability. They are the most reclaimed packaging material, with recycling programs in place across many regions. After use, these boxes can be collected, processed, and turned into new packaging, reducing the need for virgin materials. Everyday Wine and other brands have adopted corrugated packaging to lower their environmental impact and meet consumer expectations.

Environmental regulations in 2024 require:

Sustainable raw material sourcing from certified forests

Increased recycled content in packaging

Cleaner production technologies to cut emissions

Enhanced recycling programs and circular economy models

Corrugated packaging aligns with these regulations and meets the growing demand for sustainable products. Surveys show that 85% of buyers prefer packaging with eco-friendly features. Industry leaders continue to innovate, improving recycled content and circularity to boost environmental performance. Companies choose corrugated boxes not only for their protective qualities but also for their positive impact on the planet. This commitment to sustainability helps brands build trust and improve their reputation.

Choosing Corrugated Boxes

Product Needs

Selecting the right packaging starts with understanding the product’s unique requirements. Each item has specific needs based on its weight, fragility, and sensitivity to environmental factors. For fragile goods, companies often add cushioning materials such as bubble film, foam, or air column bags. These materials help absorb shocks and reduce breakage rates by up to 30%. Heavy products may require reinforced packaging, sometimes combining steel side boxes with moisture-proof films and securing them with pallets and straps. Moisture-sensitive items benefit from moisture-proof corrugated boxes or the addition of desiccants. Companies also consider the destination’s regulations, ensuring packaging meets standards like the EU IPPC or US ASTM. Environmental responsibility plays a role as well. Many businesses now choose recyclable or degradable materials to support sustainability goals.

Tip: Always match the packaging solution to the product’s characteristics to maximize protection and efficiency.

Strength Requirements

Strength is a critical factor in packaging selection. The choice of wall type—single, double, or triple—directly impacts the box’s ability to protect its contents. Single-wall corrugated boxes provide basic protection and suit lightweight items. Double-wall options offer increased durability, making them ideal for heavier products or point-of-purchase displays. Triple-wall boxes deliver the highest level of strength, often used for industrial or heavy-duty applications.

Manufacturers rely on several tests to ensure box performance:

Edge Crush Test (ECT): Measures stacking strength, essential for palletized shipments.

Bursting Test (Mullen): Assesses resistance to rupture or puncture.

Flat Crush Test (FCT): Evaluates resistance to flute crushing.

Water Absorption Test (COBB): Determines moisture resistance.

A safety factor of three is commonly used for stacking strength, following ISTA 3E standards. Companies may optimize costs by adjusting pallet design and selecting boxes with appropriate ECT values. This approach maintains safety while reducing material use.

Size and Style

Choosing the correct size and style ensures the packaging fits the product and shipping method. Boxes that are too large waste material and increase shipping costs. Boxes that are too small risk damaging the product. Companies select box styles based on product fit and required strength. The Regular Slotted Container (RSC) is the most common style, offering standard strength and versatility. Full Overlap Containers (FOL) provide double-layer strength on the top and bottom, ideal for heavy or fragile items. One Piece Folders (OPF) work well for books or media, while Full Telescopic Designs (FTD) offer twin walls for added protection.

Box Style | Best For | Key Feature |

|---|---|---|

RSC | General shipping | Standard strength |

FOL | Heavy or fragile items | Double-layer top and bottom |

OPF | Books, media | Sleek, functional |

FTD | High-strength needs | Twin walls |

Selecting the right size and style not only protects the product but also improves cost efficiency and supports branding efforts.

Industry Fit

Selecting the right corrugated box depends on the industry’s unique needs. Each sector faces different challenges in packaging, shipping, and presentation. Companies must match box features to their products and supply chain requirements.

E-commerce and Retail

E-commerce businesses need packaging that protects products during long shipping journeys. They often choose single wall or double wall boxes with C-flute or E-flute. These options offer a balance of strength and lightweight design. Retailers may focus on branding. They select boxes with high-quality printing surfaces, such as E-flute or F-flute, to display logos and graphics. Custom die-cut styles help create memorable unboxing experiences.

Food and Beverage

The food industry requires boxes that keep products fresh and safe. Ventilated corrugated boxes work well for fruits and vegetables. Double wall or triple wall boxes protect bottled drinks and heavy items. Food-grade liners and moisture-resistant coatings prevent contamination and spoilage. Many companies print product information and safety labels directly on the box.

Industrial and Manufacturing

Heavy machinery, auto parts, and electronics need strong protection. Triple wall boxes with A-flute or B-flute provide maximum strength and cushioning. These boxes support heavy loads and resist crushing. Manufacturers often use full overlap or telescoping styles for added durability. Custom inserts and padding secure fragile components.

Apparel and Consumer Goods

Clothing brands prefer lightweight, attractive packaging. Single wall boxes with E-flute or F-flute offer a smooth surface for printing and easy folding. Die-cut styles allow for unique shapes and easy assembly. These boxes help brands stand out on store shelves.

Pharmaceutical and Medical

Medical products demand strict hygiene and security. Corrugated boxes with tamper-evident seals and food-safe liners meet these needs. Double wall construction protects sensitive equipment during transit. Clear labeling and custom printing ensure compliance with regulations.

Industry | Recommended Box Type | Key Features |

|---|---|---|

E-commerce/Retail | Single/Double Wall, E/F-Flute | Branding, lightweight, printability |

Food & Beverage | Double/Triple Wall, Vented | Moisture resistance, food safety |

Industrial | Triple Wall, A/B-Flute | Heavy-duty, cushioning, inserts |

Apparel | Single Wall, E/F-Flute | Attractive, easy to fold, custom |

Medical | Double Wall, Tamper-evident | Hygiene, security, labeling |

Tip: Companies should review their product’s weight, fragility, and shipping method before choosing a box. The right fit improves protection, efficiency, and brand image.

Customization

Size and Shape

Corrugated boxes offer remarkable flexibility in size and shape. Manufacturers can design boxes to fit almost any product, from small electronics to large automotive parts. Custom sizing reduces wasted space, which helps lower shipping costs and improves product protection. Businesses often request boxes with unique dimensions to match their products exactly. This approach prevents movement during transit and reduces the need for extra packing materials.

The demand for tailored packaging continues to rise. E-commerce companies, for example, rely on custom-sized boxes to ship a wide variety of goods. Regional manufacturing hubs now support fast turnaround and on-demand production, making it easier for brands to get the exact box they need. In the automotive sector, more than 50% of spare parts ship in custom corrugated boxes, reflecting the importance of precise sizing.

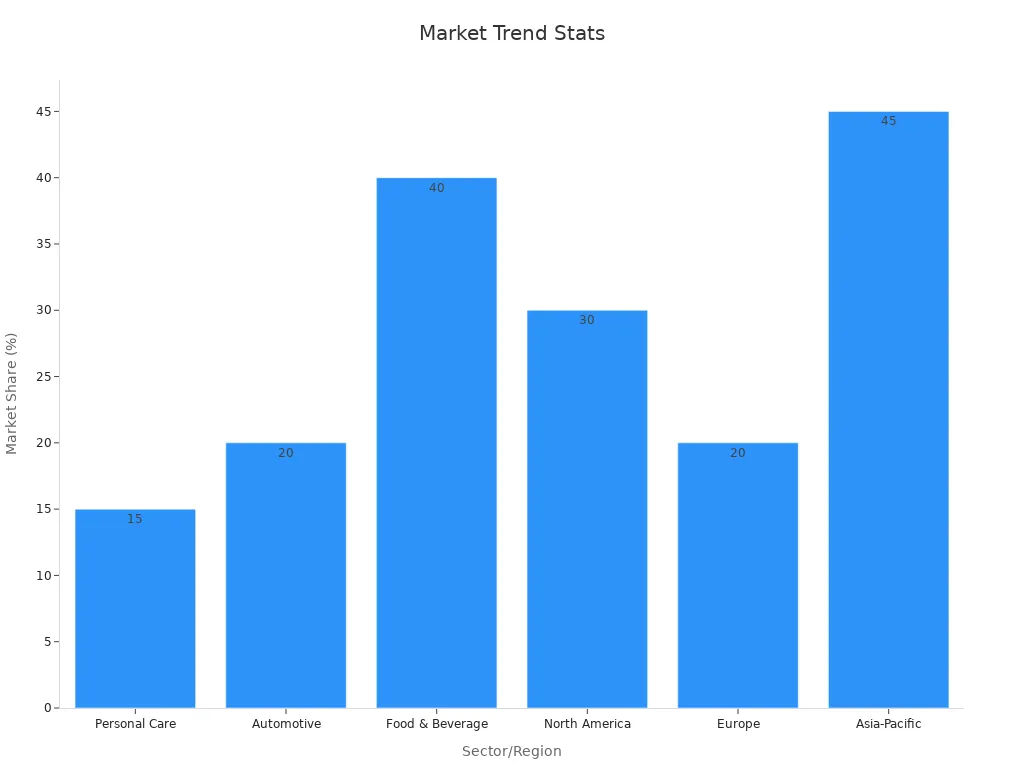

Printing

Printing transforms corrugated boxes from simple containers into powerful branding tools. Advances in digital printing technology allow for high-quality graphics, logos, and product information on both the exterior and interior surfaces. Companies use printed boxes to enhance shelf visibility and engage consumers. Retail-ready packaging with vibrant graphics stands out in stores and online.

The market shows a clear trend toward custom printed packaging. In the personal care sector, 40% of brands now use custom-printed corrugated boxes. Digital printing supports shorter production runs, which helps businesses launch seasonal promotions or region-specific designs quickly. Many food and beverage companies print product details and safety information directly on the box, improving communication and compliance.

Printing on corrugated boxes not only boosts brand recognition but also supports marketing campaigns and customer loyalty.

Special Features

Modern corrugated boxes can include a range of special features to meet specific needs. Smart packaging elements, such as QR codes, enable interactive experiences and product tracking. Some boxes use augmented reality or AI-assisted design tools to create unique customer interactions. Moisture-resistant coatings protect food and dairy products, while tamper-evident seals ensure product safety in the medical and pharmaceutical industries.

The following table highlights key trends and features across sectors and regions:

Sector / Region | Customization Trends and Features |

|---|---|

Personal Care | Eco-friendly materials, custom printing, premium finishes |

Automotive | Custom sizing, reinforced structures, smart tracking |

Food & Beverage | Moisture resistance, food-safe liners, printed product info |

North America | High demand for recyclable, branded, and digitally printed packaging |

Europe | Sustainable materials, digital printing, innovative designs |

Asia-Pacific | Rapid growth in industrial and e-commerce packaging, smart features |

Customization in corrugated packaging supports branding, product safety, and sustainability. As technology advances, businesses gain more options to create packaging that meets their exact needs and appeals to modern consumers.

Testing and Quality

Edge Crush Test

The Edge Crush Test (ECT) stands as a key measure of a corrugated box’s strength. This test evaluates how much compressive force the edge of a piece of corrugated board can withstand before it collapses. Manufacturers use ECT results to determine stacking strength, which is critical for boxes that will be piled on pallets or stored in warehouses. The ECT value, expressed in pounds per inch (for example, 32 ECT), tells users how much weight the box can handle along its edge.

Industry organizations such as the Fiber Box Association (FBA) and the Technical Association of the Pulp and Paper Industry (TAPPI) oversee these tests. Regular ECT testing ensures that boxes meet published acceptance criteria and comply with legal standards. The Box Maker’s Certificate (BMC) printed on each box includes the ECT rating, manufacturer details, and other key information. This certificate acts as a legally binding mark, confirming that the box meets minimum strength requirements set by Rule 41. Manufacturers must pass periodic audits to maintain compliance, which helps guarantee ongoing product reliability.

Tip: ECT-rated boxes are ideal for stacking and shipping applications where vertical compression is a concern.

Burst Test

The Burst Test, also known as the Mullen Test, measures a box’s resistance to external pressure and puncture. During this test, technicians apply increasing pressure to the surface of the corrugated board until it bursts. The result, given in pounds per square inch (psi), indicates how much force the box can withstand before failing.

This test is especially important for boxes used in shipping environments where impacts and rough handling are common. The Burst Test helps ensure that boxes protect their contents from sudden shocks or sharp objects. The BMC on each box will state whether the box passed the Mullen Test or the ECT, along with the minimum combined weight of facings and the maximum gross weight capacity. Adherence to these standards supports product safety and legal compliance, especially for export shipments.

Manufacturers monitor raw materials for paper quality and bonding to maintain high burst strength. Quality assurance teams perform regular burst testing as part of their continuous improvement programs.

Flat Crush Test

The Flat Crush Test (FCT) assesses the strength of the fluted medium inside the corrugated board. In this test, technicians apply pressure to the board’s surface until the flutes collapse. The FCT result shows how well the fluting can resist crushing forces, which is vital for protecting products from compression during stacking or transit.

Manufacturers use FCT results to validate the durability of their corrugated material. Continuous monitoring of board thickness, moisture content, and bonding ensures consistent quality. Dedicated quality assurance departments oversee these tests and inspections, making sure each batch of boxes meets strict industry standards.

Regular testing includes:

Ring Crush testing for paper strength

Compression testing for stacking resistance

Drop testing for safety-critical uses, such as UN-certified boxes

Quality inspections based on these tests help companies deliver reliable packaging that meets customer expectations and regulatory requirements. The combination of ECT, Burst, and Flat Crush Tests provides a comprehensive view of a box’s performance in real-world conditions.

Certifications

Certifications play a crucial role in the corrugated box industry. They help manufacturers, distributors, and customers verify that packaging meets strict quality, safety, and environmental standards. These certifications provide assurance that boxes perform as expected during shipping, storage, and handling.

Several organizations oversee certifications for corrugated packaging. Each group sets specific requirements and testing protocols. Companies that achieve certification demonstrate a commitment to excellence and compliance.

Key Certifications and Standards in Corrugated Packaging:

Certification/Standard | Issuing Body | Focus Area |

|---|---|---|

Box Maker’s Certificate (BMC) | Fiber Box Association (FBA) | Strength, construction, labeling |

ASTM Standards | ASTM International | Testing methods, material quality |

ISO 9001 | International Organization for Standardization | Quality management systems |

FSC Certification | Forest Stewardship Council | Sustainable sourcing, traceability |

SFI Certification | Sustainable Forestry Initiative | Responsible forestry practices |

ISTA Certification | International Safe Transit Association | Transit testing, packaging safety |

Box Maker’s Certificate (BMC):

The BMC appears on most corrugated boxes in North America. It confirms that the box meets minimum strength and construction standards. The certificate includes details such as the manufacturer’s name, box style, and test results (like ECT or Mullen Burst). Retailers and shippers rely on the BMC to ensure boxes can handle specific loads.

ASTM Standards:

ASTM International develops widely recognized standards for corrugated packaging. These standards cover testing methods, material specifications, and performance criteria. Manufacturers follow ASTM guidelines to ensure consistency and reliability.

ISO 9001:

ISO 9001 certification focuses on quality management systems. Companies with this certification show that they maintain strict quality controls throughout production. This standard helps reduce defects and improve customer satisfaction.

FSC and SFI Certifications:

Sustainability matters in packaging. The Forest Stewardship Council (FSC) and Sustainable Forestry Initiative (SFI) certify that raw materials come from responsibly managed forests. Boxes with these labels support environmental goals and traceability.

ISTA Certification:

The International Safe Transit Association (ISTA) certifies packaging for transit safety. ISTA tests simulate real-world shipping conditions, such as drops, vibrations, and compression. Boxes that pass ISTA tests help reduce product damage during transport.

Note: Certifications not only prove compliance but also build trust with customers and partners. They signal that a company values quality, safety, and sustainability.

Manufacturers often display certification marks on their packaging. These marks help buyers make informed choices. Companies that invest in certification gain a competitive edge and meet the demands of modern supply chains.

Corrugated Boxes vs Other Packaging

Cardboard

Corrugated boxes and standard cardboard boxes differ in structure and performance. Corrugated boxes use a fluted layer between two liners, which gives them strength and cushioning. Cardboard, often called paperboard, consists of a single thick layer. This makes cardboard suitable for lightweight packaging, such as cereal boxes or folders. However, it does not provide the same level of protection as corrugated packaging.

Corrugated boxes support heavier loads and resist crushing. They protect fragile items during shipping and stacking. Businesses choose corrugated boxes for shipping electronics, glassware, and industrial parts. Cardboard works best for retail packaging where strength is less important.

Corrugated packaging also offers more customization options for branding and product fit. Companies can print high-quality graphics on the surface, helping products stand out on shelves.

Plastic

Plastic packaging appears in many industries due to its durability and moisture resistance. However, several factors make corrugated boxes a preferred choice for many businesses:

Plastic containers require a higher initial investment for purchase, maintenance, and replacement.

Regular cleaning and sanitization add to operational costs for plastic packaging.

Many types of plastic are not accepted by standard recycling facilities, limiting recycling options.

Plastic packaging has a low recovery rate of about 9%, and this rate continues to decline.

Corrugated boxes have a recovery rate near 90% over the past seven years, making them the most recycled packaging material in the United States.

Corrugated boxes are biodegradable and reduce landfill waste compared to plastic.

Corrugated packaging supports a circular economy by minimizing raw material use and energy consumption.

The average corrugated box is recycled seven times and contains nearly 52% recycled material.

Corrugated boxes also offer cost advantages. They have lower initial costs and do not require expensive maintenance. Their high recyclability and renewable material content help companies meet sustainability goals.

Companies seeking to reduce their environmental impact often choose corrugated packaging over plastic.

Wood

Wooden packaging, such as crates and pallets, provides strong protection for heavy or bulky goods. Many industries use wood for transporting machinery, produce, or export shipments. Wood offers excellent durability and can be reused multiple times.

A Life Cycle Assessment (LCA) study compared wooden packaging and corrugated cardboard for transporting 1,000 tons of mandarins over 2,000 kilometers. The study found that wooden packaging produced lower greenhouse gas emissions and had a smaller water footprint than corrugated cardboard. Wood also caused less eutrophication of fresh and marine water and had a lower impact on land acidification.

Packaging Type | Greenhouse Gas Emissions | Water Footprint | Eutrophication | Land Acidification |

|---|---|---|---|---|

Wooden Packaging | Lower | Smaller | Less | Lower |

Corrugated Cardboard | Higher | Larger | More | Higher |

Corrugated boxes remain lighter and easier to customize than wood. They also offer better printability for branding. For many products, corrugated packaging provides a balance between protection, cost, and sustainability.

Businesses should consider the specific needs of their products and supply chains when choosing between corrugated, plastic, and wood packaging.

Corrugated boxes provide strong protection, durability, and sustainability for many industries. They come in different types and styles to fit specific needs. Choosing the right box helps keep products safe and supports eco-friendly goals.

Businesses can use corrugated boxes for shipping, retail, and custom packaging.

Expert advice ensures the best solution for each product.

Companies should explore custom options to maximize packaging performance.