Choosing jam packaging boxes shapes freshness, shelf life, and brand appeal. Packaging protects jam and boosts product safety.

Packaging design evokes emotions and creates memorable first impressions for jam buyers.

Boxes for Jam, Jam Gift Box, and Animal Jam Subscription Box offer options for every need.

Jam boxes with clear labels and resealable features increase convenience.

Key Takeaways

Choose jam packaging boxes that protect jars from damage and keep jam fresh by blocking air, moisture, and light.

Use eye-catching and clear packaging designs to build brand trust and attract customers with features like window cut-outs and resealable lids.

Select durable, eco-friendly materials and the right box size to reduce costs, support sustainability, and ensure safe shipping.

Jam Packaging Boxes

Protection & Freshness

Jam packaging boxes play a vital role in keeping jam fresh and safe. They shield jars from bumps and drops during shipping. The right packaging also blocks air, moisture, and light, which can spoil jam. Cap liners and vacuum-sealed lids create tight seals, stopping leaks and keeping out contaminants. These features help jam last longer and taste better. The table below shows how different packaging materials affect shelf life:

Packaging Material | Characteristics and Impact on Shelf Life |

|---|---|

Glass Jars | Excellent barrier, airtight, preserves flavor and color, extends shelf life. |

Metal Containers | Strong barrier, airtight, keeps jam quality high and shelf life long. |

Plastic Jars | Lightweight, shatterproof, but less protection from air and moisture, shorter shelf life. |

Multilayer Plastic | Good oxygen barrier, lightweight, helps keep jam fresh. |

Flexible Pouches | Light and easy to use, but less protection, shorter shelf life. |

Paper-based Packaging | Used for secondary packaging, not for direct jam contact. |

Branding & Appeal

Packaging does more than protect jam. It shapes how customers see the product. Eye-catching jam packaging boxes with clear labels, bright colors, and unique shapes attract attention. Simple designs and natural colors suggest quality and honesty. Window cut-outs let buyers see the jam inside, building trust. Many brands use packaging to tell a story or show their values. For example:

Strong brand identity connects with customers and builds loyalty.

Appealing images and fonts make jam stand out on shelves.

Simple, clean designs suggest natural and high-quality jam.

Transparent elements let customers inspect the jam before buying.

Packaging featured in ads or social media boosts sales and trust.

A well-designed box can make jam look premium and encourage repeat purchases.

Convenience & Shipping

Jam packaging boxes must make shipping and handling easy for both sellers and buyers. Sturdy packaging prevents jars from breaking during transport. Features like ergonomic handles, inserts, and lock-bottom designs help carry and protect jam jars. Clear labeling gives buyers important information at a glance. The table below compares packaging types for shipping and convenience:

Packaging Type | Key Features for Shipping and Convenience |

|---|---|

Glass Jars | Premium look, but heavy and fragile, needs careful handling. |

Plastic Jars | Lightweight, durable, easier to ship, less risk of breakage. |

Metal Tins | Strong and protective, but heavier and harder to open. |

Flexible Pouches | Very light, easy to carry, but less premium feel. |

Jam packaging boxes with these features help retailers display products neatly and make it easy for customers to carry and store jam at home.

Types of Jam Packaging Boxes

Choosing the right jam packaging boxes helps protect jam, enhance its appearance, and support brand goals. Several types of jam packaging boxes exist, each with unique strengths for different business needs. Other packaging solutions, such as pouches and glass jars, also play a role, but boxes remain the most popular for shipping and retail display.

Cardboard & Corrugated

Cardboard and corrugated boxes are the most common jam packaging box options. Cardboard boxes use a single flat layer, making them lightweight and suitable for local sales or as filler. Corrugated boxes have three layers, including a fluted middle layer that absorbs impact. This design makes corrugated boxes stronger and better for shipping fragile jam jars. Corrugated boxes also offer better protection, are reusable, and have a high recycling rate. Cardboard boxes are usually single-use and more prone to damage. Corrugated packaging costs more but saves money by reducing product loss during transport.

Tip: Corrugated cardboard is made from recycled fibers and starch-based adhesives, making it a sustainable choice for jam packaging.

Box Type | Durability | Protection | Reusability | Best Use |

|---|---|---|---|---|

Cardboard | Low | Low | Single-use | Local retail, fillers |

Corrugated | High | High | Reusable | Shipping, glass jars |

Window & Gift Boxes

Window and gift boxes add visual appeal to jam packaging. Window boxes use clear PVC sheets or flaps, letting customers see the jam without opening the box. This feature builds trust and makes the product more attractive. Gift boxes often include colorful designs, special coatings, and inserts to secure jars. Handles and magnetic closures add convenience. These packaging styles work well for holidays, weddings, birthdays, and corporate events. They create a memorable unboxing experience and encourage impulse buys.

Window boxes showcase jam and highlight labels.

Gift boxes suit special occasions and add a personal touch.

Inserts keep jars safe and prevent damage.

Custom Printed Options

Custom printed jam packaging boxes help brands stand out. Companies can choose materials like kraft, corrugated, or luxury rigid boxes. Styles include tuck tops, snap locks, and display boxes with compartments. Printing techniques such as digital, offset, and foil stamping create vibrant graphics. Finishes like matte, gloss, or embossing add texture and shine. Custom packaging with logos and brand stories increases recognition and loyalty. Eco-friendly materials also build a positive brand image. Custom printed boxes make the unboxing experience special and encourage repeat purchases.

Note: Custom printed packaging acts as a silent salesperson, building emotional connections and trust with customers.

Other packaging solutions, such as pouches, glass jar packaging box, and mason jar packaging box, offer alternatives for jam. However, the main types of jam packaging boxes—cardboard, corrugated, window, and custom printed—provide the best mix of protection, appeal, and branding for most jam businesses.

Choosing the Best Box

Material & Durability

Selecting the right material for jam packaging boxes ensures that jam arrives safely and remains fresh. Manufacturers evaluate material strength and seam quality by checking adhesive type, stitch wire selection, and machine calibration. They inspect materials and test for durability using tensile strength, compression, and impact tests. Environmental chambers and vibration testers simulate shipping conditions. Companies follow standards such as ASTM, ISTA, and ISO to guarantee reliability. Outsourcing to packaging testing companies provides thorough results. Multi-point quality checks, including operator skill and machine calibration, maintain consistent strength.

Common material failures can affect jam packaging boxes. The table below outlines typical issues and prevention methods:

Material Failure Type | Causes/Issues | Prevention Methods |

|---|---|---|

Box Jams | Improper material thickness or size; carton blanks too hard/soft or mis-sized | Use carton stock with correct thickness and finish; clean and lubricate transport belts; size carton guides properly |

Glue/Adhesive Problems | Poor or leaking glue; incorrect glue temperature; clogged glue nozzles | Maintain glue temperature within range; use compatible adhesive; clean glue nozzles regularly |

Folding/Sealing Errors | Mis-set folding guides; improper fold pressure; damaged or crushed boxes | Adjust folding guides to box size; set correct fold pressure; perform test runs to ensure neat folds |

Box Size Mismatch | Running wrong carton size without retooling; incorrect mold settings | Adjust mold and machine parameters for box size changes; pre-run checks of box flatness and print |

Durable jam packaging boxes protect jam from damage during transit and storage. Reliable packaging reduces returns and maintains customer trust.

Sustainability

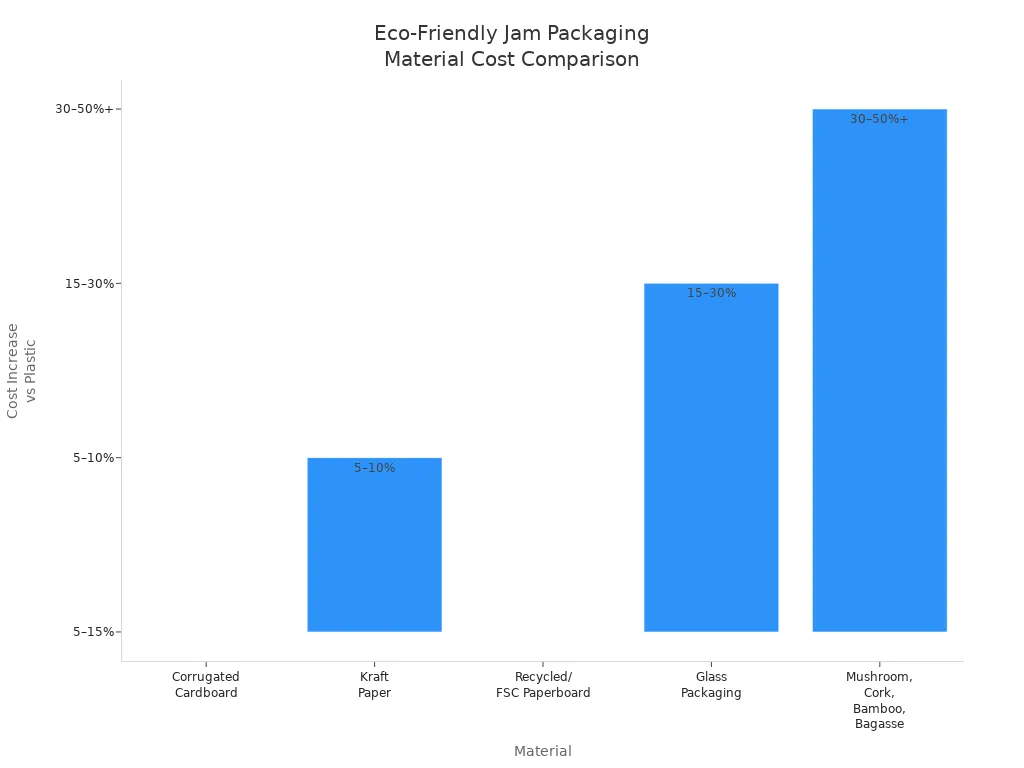

Eco-friendly packaging has become a priority for many jam producers. Corrugated cardboard, kraft paper, and recycled paperboard offer strong protection and high recyclability. Glass packaging provides premium quality and endless recyclability, though it increases shipping costs. Mushroom, cork, bamboo, and bagasse materials suit luxury jam packaging boxes but cost more.

Material | Cost Compared to Plastic | Recyclability / Compostability | Performance / Use Case Highlights |

|---|---|---|---|

Corrugated Cardboard | 5–15% higher | Biodegradable, widely recyclable | Cost-effective, good for small businesses, strong and protective |

Kraft Paper | 5–10% higher | ~90–95% recycling rate, compostable if uncoated | Sturdy, tear-resistant, affordable, widely available |

Recycled / FSC Paperboard | 5–15% higher | 85–90% recycling rate, compostable if uncoated | Durable, sustainable, good for retail and food cartons |

Glass Packaging | 15–30% higher | Endlessly recyclable, not compostable | Premium quality, preserves product purity, heavier shipping cost |

Mushroom, Cork, Bamboo, Bagasse | 30–50%+ higher | Eco-friendly but less common | Used mainly for premium/luxury packaging due to higher cost |

Sustainable jam packaging boxes help brands appeal to environmentally conscious customers. Minimalistic and eco-friendly packaging reduces costs and environmental impact. Companies that adopt sustainable packaging strategies often see improved profitability and enhanced brand reputation.

Customization

Customization transforms jam packaging boxes into branding tools. Companies use brand colors, logos, embossing, and foil stamping to create a unique look. Personalized touches, such as thank-you notes or discount codes, deepen customer relationships. Custom packaging protects jam during shipping and maintains brand reputation. Social media unboxing videos showcase thoughtful packaging and increase product visibility.

Custom packaging supports brand identity and marketing strategy.

Colors, textures, and finishes attract target consumers and elevate perceived quality.

Personalized labels improve consumer-centric packaging and build trust.

Consistent design across all packaging touchpoints builds recognition.

Small businesses benefit from customization by differentiating their jam in competitive markets. Customization also supports professional appearance and market success.

Cost & Bulk Buying

Cost-effective jam packaging boxes help businesses manage expenses while maintaining quality. Recommended materials include cardboard, kraft paper, rigid, and corrugated cardboard. These materials offer durability, protection, and sustainability. Standard printing methods, such as CMYK and digital printing, balance quality and price. Basic finishing options, like gloss or matte lamination, enhance appearance without significant cost increase.

Manufacturing processes such as die cutting, gluing, scoring, and perforation add value without extra cost. Bulk ordering reduces unit costs and improves cost-effectiveness. For example, a startup reduced unit cost from $0.28 to $0.21 by ordering in bulk, saving 25%. Wholesale pricing starts at $0.50 per box for orders ranging from 100 to 500,000 units.

Quantity Range | Starting Unit Price | Key Benefit |

|---|---|---|

100 - 500,000 units | From $0.50 per box | Wholesale pricing reduces per-unit cost |

Small to large scale | Affordable solutions | Durable, quality boxes without cost compromise |

Bulk buying helps small and medium businesses lower costs and maintain high-quality jam packaging boxes.

Size & Fit

Proper sizing of jam packaging boxes ensures product safety and controls shipping costs. Standard sizes match common jar dimensions, providing enough space for padding and protection. Oversized boxes cause unwanted movement, increasing the risk of damage. Shipping companies use dimensional weight pricing, so larger boxes lead to higher costs. Product damage from poor packaging results in costly returns and loss of customer loyalty.

Dimensions (inches) | Jar Height Compatibility (inches) | Jar Diameter Compatibility (inches) | |

|---|---|---|---|

Portavasetti Italian Carriers | Various sizes from 4-3/8" to 8-3/8" height | Fits jars from short 4-3/8" H to tall 8-3/8" H | Designed to hold 2 to 3 jars with dividers |

Seta Nero Window Boxes | 6" x 5-3/8" x 1-3/8" and 9" x 5-3/8" x 1-3/8" | Holds 4 bottles (smaller box) and 6 bottles (larger box) | Includes optional inserts for bottle separation |

Popular jar sizes include:

Medium jars: 250-400 ml (300-480g jam)

Large jars: 500-700 ml (600-850g jam)

Standard jars: 350ml to 380ml, common for supermarket jam

Oversized jars: Larger than 1000ml, used for bulk gifting

Selecting the right box size prevents damage and enhances customer satisfaction. Sturdy, new boxes provide structural integrity and better protection for jam.

Selecting jam packaging boxes requires balancing protection, branding, sustainability, and cost. The table below highlights key factors for effective packaging decisions:

Factor | Benefit |

|---|---|

Protection | Extends shelf life, prevents spoilage |

Branding | Enhances consumer appeal |

Sustainability | Reduces environmental impact |

Cost | Improves business efficiency |

Explore customized packaging options to boost brand identity and customer satisfaction. Review available packaging solutions and choose the best fit for business growth.