Box Type | Market Share (2024) | Reason for Dominance |

|---|---|---|

Cost-effectiveness and versatility |

A regular slotted container is recognized as the most widely used box style in packaging. This regular slotted container box is designed with four equal flaps on both the top and bottom, which meet at the center to allow for secure sealing. Manufacturers choose the regular slotted container for its strength, durability, and efficient use of materials. While the overlap slotted container features a different flap configuration, the Regular Slotted Container continues to be the preferred choice due to its adaptability across various industries.

Key Takeaways

Regular slotted containers use equal-length flaps that meet in the center, making them strong, easy to assemble, and efficient in material use.

These boxes save costs by using less material, shipping flat to save space, and working well with automated packaging systems.

RSCs are highly versatile, fitting many product sizes and industries, and they support eco-friendly packaging with recyclable materials.

Regular Slotted Container Design

Flap Structure

A regular slotted container features a unique flap design that sets it apart from other box styles. All four flaps on the top and bottom have equal length, with the two outer flaps each measuring half the width of the container. When folded, these longest flaps meet perfectly at the center, creating a secure closure. This arrangement strengthens the box and helps it resist impacts during shipping and handling. The equal-length flaps also make the box easy to assemble and allow for efficient stacking. Manufacturers follow strict industry tolerances to ensure consistency and squareness in every box.

Parameter | Tolerance / Dimension | Notes |

|---|---|---|

Panel Size (scoreline to scoreline) | ± 1/16 inch (1.5 mm) | Ensures panel consistency |

Slot Depth Variation | Critical for flap folding | |

Manufacturer's Joint Gap | 1/8 inch (3 mm) min to 1/2 inch (12.5 mm) max | Ensures box squareness |

Flap Score Alignment | Max 3/16 inch (4.5 mm) | Maintains proper flap folding |

The regular slotted container design minimizes material waste because the flaps meet in the middle, requiring less cutting and fewer complex shapes than an overlap slotted container.

Materials

Manufacturers typically use corrugated cardboard to produce regular slotted containers. This material consists of two sheets of kraft paper sandwiching a fluted layer, which provides cushioning and strength. Most regular slotted containers use single-wall corrugated cardboard, balancing protection and cost for general packaging needs. For heavier products, double-wall or triple-wall boards offer extra durability.

Material Type | ECT Rating (lb/in) | Suitable Product Weight (lbs) | |

|---|---|---|---|

Standard Single Wall | 200 | 32 | 25 - 40 |

Heavy Duty Single Wall | 275 | 44 | Up to 65 |

Heavy Duty Double Wall | 275 | 48 | Up to 80 |

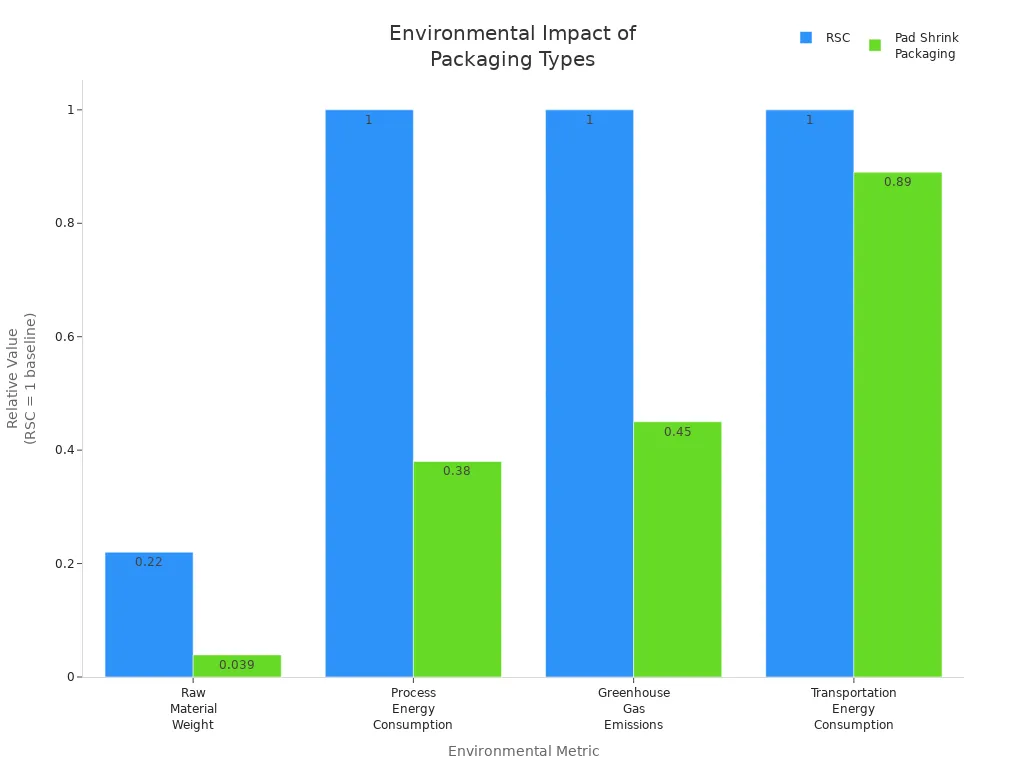

Sustainable materials play a growing role in packaging. Using recycled cardboard and eco-friendly adhesives reduces carbon emissions and resource consumption. These choices help companies meet consumer demand for greener products and support circular economy principles.

Tip: Choosing recyclable materials for your corrugated cardboard box can lower your environmental footprint and align with sustainability goals.

Assembly

The assembly process for a regular slotted container is straightforward and efficient. Manufacturers start by selecting the right corrugated board based on product weight and protection needs. They print branding or product information, then cut the sheets into flat blanks with precise dimensions. Machines crease and slot the blanks, making folding easy. High-speed gluing machines or manual tape seal the flaps, forming the final box.

1. Material Selection: Choose corrugated board with the needed strength. 2. Printing and Cutting: Print and cut sheets to size. 3. Creasing and Slotting: Create score lines and slots for folding. 4. Folding and Gluing: Fold along creases and glue the manufacturer’s joint. 5. Quality Control: Inspect for strength and accuracy.

The regular slotted container design uses a single sheet of board and equal-length flaps, which reduces waste compared to more complex boxes like the overlap slotted container. This efficient process keeps costs low and supports sustainability.

Feature | RSC Box | Die-Cut Box |

|---|---|---|

Manufacturing Process | Complex, custom die-cutting | |

Material Usage | Tailored cuts, more waste |

Benefits and Uses

Cost and Efficiency

Companies choose the regular slotted container for its economical and highly efficient design. The structure uses less material than many alternatives, which lowers purchasing costs and reduces waste. Rigid boxes, for example, cost more due to their complex construction and premium materials. Folding cartons offer flexibility but may become more expensive depending on the paperboard used. In contrast, regular slotted containers remain affordable for most packaging needs.

Businesses report significant cost savings after switching to this box style. The design maximizes space during transit, which leads to lower shipping costs. Durability protects products, reducing losses from damage. The ability to ship flat saves warehouse space before use. Automated packaging systems handle these boxes easily, which speeds up fulfillment and reduces labor costs.

Aspect | Explanation |

|---|---|

RSCs ship flat, saving warehouse space before use, and their overlapping flaps allow higher stacking during shipment, maximizing space utilization. | |

Streamlining Packaging | Designed for quick assembly and compatibility with automated machinery, reducing manual labor and errors, thus speeding up packaging processes. |

Customization | Can be tailored to product size and branding, reducing the need for extra internal packaging and enhancing marketing impact. |

Cost Efficiency | Reduces internal packaging needs, minimizes waste, and lowers logistics costs due to lighter package weight. |

Environmental Impact | Higher stacking and space savings reduce logistics costs and carbon footprint, supporting sustainability goals. |

Note: RSC boxes use less material than FOL boxes, making them less expensive to purchase and more sustainable.

Versatility

Regular slotted containers adapt to a wide range of applications. Manufacturers can customize the size and material to fit almost any product, from small electronics to large industrial goods. This flexibility supports shipping small to large products with ease. Material options, such as single-wall or double-wall corrugated, allow the box to handle different weights and levels of fragility.

RSCs can be custom-sized for:

Small items like electronics, tools, and cosmetics

Medium items such as apparel, kitchenware, and hardware

Large items including industrial, bulk, or wholesale products

Material choices include:

Single-wall corrugated for lightweight packaging

Double-wall corrugated for heavier or fragile items

Kraft board and white corrugated for eco-friendly or branded packaging

The highly efficient design of the regular slotted container minimizes wasted space and filler material. This makes it suitable for nearly any product size or weight. RSCs also support full-color printing, surface finishes, and functional add-ons like die-cut handles or tear strips. These features enhance branding and product presentation, especially in retail and e-commerce.

Box Style | Description | Use Case / Versatility |

|---|---|---|

Most commonly used corrugated box; flaps meet in the center; produces almost no waste when cut. | Highly versatile; suitable for almost anything; efficient in material use. | |

Full Overlap Slotted Container (FOL) | All flaps same length; outer flaps completely overlap. | Provides extra cushioning, protection, and stacking strength; especially resistant to rough handling. |

Center Special Slotted Container | Inner and outer flaps of different lengths; flaps meet in the center. | Offers more protection and a level base; uses more corrugated material. |

Center Special Overlap Slotted Container | Inner flaps meet at center; outer flaps overlap partially. | Provides a level surface with less material waste than Center Special Slotted Container. |

While FOL boxes offer greater protection against rough handling due to overlapping flaps, RSCs remain the most versatile and cost-effective choice for general packaging.

Common Applications

Regular slotted containers serve many industries because of their adaptability and reliability. Companies use them for shipping and storage, retail packaging, and product display. The most common applications include:

Electronics and technology

Automotive parts

Pharmaceutical and healthcare

Manufacturing and industrial goods

Automated packaging and fulfillment systems rely on RSCs for their robust construction and consistent sizing. Case erectors and packers can quickly form, fill, and seal these boxes, supporting high-volume operations. RSCs also meet strict industry standards, such as Rule 41 and Item 222, which specify requirements for strength, caliper, and edge crush resistance. These standards ensure that boxes perform well during shipping, even under demanding conditions.

Tip: For fragile items, companies should use double-wall corrugated RSCs, add internal cushioning, and seal boxes securely to enhance protection.

The regular slotted container stands out as a practical solution for businesses that need reliable, customizable, and cost-effective packaging across a wide range of applications.

Regular slotted containers stand out for their cost-effectiveness, quick assembly, and strong protection.

Companies value their ability to ship flat, save space, and support sustainability goals.

Made from recyclable materials, RSCs offer practical, eco-friendly packaging for many industries.

Choosing RSCs helps businesses balance durability, efficiency, and environmental responsibility.