Imagine you’ve got a product that’s long, narrow, or awkward — maybe a framed print, a metal rod, or a tall electronic device. A regular shipping box is either overkill (lots of empty space) or too tight (risking damage). Enter the telescope box (also known as telescopic box, telescoping box, or telescopic boxes) — a smart, flexible packaging solution that’s part box, part puzzle piece.

In this post, we’ll dive into what telescope boxes are, why brands love them, real-world benefits, how to choose or design one, and some FAQs to clear up common questions.

What Exactly Is a Telescope Box / Telescopic Box?

At its core, a telescope box is a two-piece container: a base and a lid (or cover) that slide over or into each other. Because of this sliding mechanism, the effective height (or depth) can be adjusted to snugly fit different product sizes. In other words:

- Telescoping box / telescopic box= two parts that overlap

- Telescoping shipping boxes= the same idea, structured for shipping, transit, and durability

- Telescopic boxes(plural) / telescoping boxes = generic/plural forms

Depending on design, the “lid” piece may fully enclose the base (full telescope style) or only partially overlap (partial telescope).

This simple sliding design gives the box flexibility: you can adjust how much coverage the lid gives (i.e. how far it overlaps), which allows you to use one box “shell” for multiple product heights.

Types of Telescope / Telescopic / Telescoping Boxes

Here are common variants you’ll find:

| Type | Description / Lid Coverage | Best-Use Cases |

|---|---|---|

| Full Telescope | The lid completely covers the base or overlaps a majority of its depth | When you need full side-wall protection—heavy gear, fragile items, premium packaging |

| Partial Telescope | Lid covers only part of the base depth | Good when you want a visual contrast or when product stability is less critical |

| Double Cover / Interlocking Double Cover | A four-sided tube (strip) forms the body, then trays cover both ends; sometimes flanges interlock | Great for large machinery, long pieces, pipes — when you can’t drop the product into a preassembled box |

You may also see full telescope half slotted boxes (where the body is half-slotted, making assembly faster) or design style containers under the broader umbrella of telescopic boxes.

Why Choose Telescoping Shipping Boxes?

Why go through the extra step of designing a telescoping box instead of a standard fixed box? Because the advantages often outweigh the effort. Here are major benefits:

1. Versatility & Inventory Efficiency

With adjustable height, a single telescopic box can serve multiple product variants. You don’t need a dozen box sizes in stock — you just adjust overlap. This reduces SKU complexity and warehouse clutter.

In fact, studies on optimizing packaging choices show that suboptimal box sizing leads to wasted space (and cost). One work on box-size selection (for e-commerce) pointed out that reducing “air volume” in boxes meaningfully cuts shipping waste and costs.

2. Better Protection & Stability

Because the lid overlaps, the side walls reinforce each other. A tight lid fit reduces product movement and shifting, which is often a prime culprit of damage in transit.

Corrugated material provides cushioning and crush resistance; combining two overlapping layers of board around the sides gives extra rigidity.

Also, package cushioning (foam, paper pads, molded inserts) pairs well inside a snug box to absorb shock, letting the box walls handle compressive forces.

3. Space & Logistics Efficiency

Telescoping boxes can be shipped and stored flat (before use), taking up minimal space. Once you need to pack, you just pull up or slide the pieces.

Less bulky inventory means lower storage costs. Also, during shipping, fewer voids and less dunnage mean you can pack more efficiently into pallets or crates.

4. Customization & Brand Appeal

Because telescoping boxes are often two-piece and sturdy, they lend themselves to premium finishes — custom printing, logos, embossing, or luxury unboxing design. For many brands, the unboxing experience is crucial.

5. Cost Savings (Over Time)

Though telescopic boxes may cost more per unit than a simple box, their flexibility and better protection can reduce returns, damage, and over-purchase of packaging materials. Also, using one style for multiple products cuts cost in the long run.

In projections, the telescoping / telescope box market is expected to grow, partly because of their adoption in shipping and logistics.

Designing & Choosing the Right Telescopic / Telescoping Box

To get the benefits, you’ll want to think through design choices. Here’s a guide:

Key Design Decisions & Trade-Offs

- Flute Type / Board Strength

Corrugated boxes use flutes (A, C, etc.). Stronger (thicker) flutes resist crushing but cost more. Use stronger boards for heavy or fragile items.

Also consider the Edge Crush Test (ECT) or burst strength ratings of the corrugated board. These represent how much pressure the board can resist. - Overlap Depth (Lid / Base)

More overlap = more structural reinforcement but uses more material. Find balance that gives protection without waste. - Wall Construction

Single-wall is enough for many items; double-wall or even triple-wall is better for heavy or stack-intensive shipments. - Recycled vs Virgin Fiber Content

Using high recycled content is good for sustainability, but at high levels it can degrade strength (especially in humid conditions). Packaging engineers often balance performance vs. eco goals. - Internal Inserts & Cushioning

Use foam, molded pulp, or corrugated inserts to immobilize products. Keep void fill minimal by precise sizing. - Hand Holes, Die Cuts, Side Access

If your product is wide or has fragile surfaces, side-loading boxes or hand-holes help avoid damaging surfaces during packing.

7.Testing — Compression / Package Testing

Use compression tests to simulate stacking loads. The container compression test is a standard way to see how much force a box can handle before deforming.

A Sample Design Process

Let’s imagine you have a framed print that’s 30 cm × 40 cm and thickness varies (depending on frame). You want one telescopic box to cover thicknesses from 2 cm to 6 cm.

- Decide base depth = 6 cm

- Lid must overlap enough that when closed down to 2 cm, there’s still side coverage

- Choose board strength (perhaps C-flute)

- Design foam or corrugated inserts matching the dimensions

- Add hand holes for safer lifting

- Test compression with stacked boxes to ensure it withstands warehouse conditions

You may prototype with a few units and simulate shipping (drops, vibration) to refine.

Real Use Cases & Market Insights

Market Trends

- The telescope / telescope boxmarket is large and growing. In 2025, it was projected to reach USD 209.1 billion, with shipping & logistics contributing ~32.8 % of that demand.

- The full telescope style (i.e. lids that fully overlap) is expected to dominate, holding ~57.3 % shareof product types, because of its structural advantages.

Industries That Use Telescoping / Telescopic Boxes

- E-commerce / Retail: For electronics, cosmetics, fashion accessories. The telescopic design helps adjust for seasonal or product size variations.

- Industrial / Machinery: For parts, tooling, or long components. The double cover / tube format is common.

- Art / Framing / Posters: For shipping paintings, prints, and framed work. The snug fit and protection are valuable.

- Luxury / Gift Packaging: The premium feel and structural integrity boost perceived value.

Example: Long Shipping & Telescope Box Combination

In long items (e.g. rods, carpets), telescoping long shipping boxes (or combining telescopic design with tube formats) is common — the sliding cover adds protection to edges and sides.

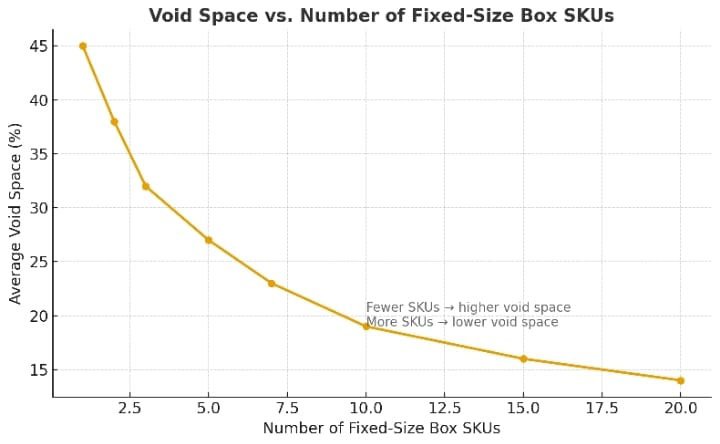

Graph: Void Space vs. Number of Fixed-Size Box SKUs

Here’s a conceptual graph so you can visualize.

As SKU count increases, average void space drops — but inventory complexity and cost grow. A telescoping box (or few telescoping sizes) may offer lower voids with fewer SKUs. This is similar to clustering/optimization results from box-selection research.

Final Thoughts & Tips

If you’re contemplating using telescope boxes / telescopic boxes / telescoping shipping boxes / telescoping boxes in your operation, here are some action ideas:

- Prototype & test early— don’t wait for full scale; build a few prototypes and subject them to drop, vibration, compression.

- Analyze your SKU mix— see how many box sizes you currently maintain and how much void you carry.

- Partner with a packaging supplierexperienced in telescopic designs — they can offer valuable design input.

- Document pack processes— include tolerance ranges, acceptable lid fit, insertion instructions, etc.

- Monitor damage/return ratesclosely pre- and post- implementation.

Telescopic boxes bring an elegant, flexible, and protective approach to packaging — bridging the gap between form and function.

FAQ — Telescoping / Telescope / Telescopic Boxes Questions

Can telescoping boxes handle heavy products?

Yes — but you must choose a stronger board (double/triple wall), sufficient overlap, and possibly reinforcement. The sliding cover also helps lock in side support.

Are telescoping shipping boxes more expensive?

Upfront they may cost more than a plain box, but savings from reduced returns, fewer purchased SKUs, less filler, and better transit protection often offset the cost.

Can I recycle or reuse telescopic boxes?

Yes—if made from corrugated board, they’re recyclable. Reuse depends on wear; because of their sturdier structure, many can be reused several times.

Does the sliding lid get loose over time?

If designed well (tight tolerances, correct overlap, secure fit), it should stay firm. But repeated heavy use or abuse may loosen the fit, so inspect lids in reuse cycles.

Do telescoping boxes work for odd shapes (e.g. curved, non-cuboid)?

They work best for items that can be approximated by a rectangular prism. For very odd shapes, you might combine the telescopic envelope with internal cradles / inserts custom cut to shape.

How to choose between telescoping vs fixed boxes?

If your product line has significant variation in shape or length, or you want to minimize packaging SKUs, telescoping is strong. If your product is always the same size and cheap packaging is priority, fixed boxes may still win in cost.