Everything You Need to Know to Elevate Your Packaging Game

Imagine you’ve ordered a special gadget online. It arrives, you tear open the box, and instead of chaos — items bouncing around, scratched corners, loose foam bits — everything is snug, pristine, beautifully presented. That miracle? Likely thanks to well-designed box inserts.

In the competitive world of e-commerce, branding, and customer experience, custom boxes with inserts are quietly doing a lot of heavy lifting. In this article, we’ll explore what box inserts are, why they matter, the different types, how to choose or design them, some case studies, a comparison table, and FAQs. By the end, you’ll see how inserts like custom foam box inserts or custom packaging boxes with foam inserts can make a difference.

What Exactly Are Box Inserts?

Box inserts refer to any interior structure inside a box or mailer, designed to hold a product in place, cushion it, organize parts, or enhance presentation. They can be made of foam, cardboard, plastic, molded pulp, etc. They might be simple – a cardboard divider – or more elaborate – a precision custom foam insert shaped to match the product inside.

Some key terms:

| Term | What It Typically Means |

|---|---|

| Custom insert for boxes | Any insert designed specifically to your product(s) and box dimensions. |

| Custom foam box inserts / custom foam insert | Box inserts made of foam (polyethylene foam, polyurethane foam, etc.), shaped to protect & cushion. |

| Custom mailer box with insert / custom mailer boxes with inserts | Mailer-style boxes (for shipping via mail) that include internal structure/inserts to protect or present the item inside. |

| Custom box with insert / custom packaging boxes with foam inserts | More general: could be non-mailer box, could be for display, retail or gift packaging, etc. |

Why Do Companies Use Inserts?

Here are some of the main benefits of using inserts, especially custom foam inserts for boxes, custom box with foam insert, etc.:

1.Protection in Transit

One of the biggest benefits of foam inserts is excellent protection against knocks, shakes, drops during shipment.

A case study: a company switched to custom foam inserts that eliminated product movement in crates, and their freight damage claims dropped dramatically.

2.Enhanced Presentation & Brand Perception

The “unboxing experience” matters. A well-designed package with inserts looks thoughtful, high quality, and conveys care. Customers feel better about the purchase.

3.Reduced Returns & Costs

When products arrive damaged, there’s cost in replacing, in shipping, in customer dissatisfaction. Inserts help reduce damage, thus saving money.

4.Customer Loyalty & Word-of-Mouth

A memorable unboxing experience is shareable. People post photos or videos. They come back.

5.Organization & Efficiency

If you have multiple components, or delicate parts, inserts can keep everything in place, preventing jostling or damage. Also helps in packing/unpacking efficiency.

6.Sustainability (if done well)

There are concerns with foam materials (especially non-recyclable ones), but there are more eco-friendly foam options, recyclable inserts, or insert designs that reduce waste.

Types of Box Inserts

Here are common kinds of inserts, with pros & cons, to help you decide which fits your product or brand best.

| Type | Common Materials | Pros | Cons |

|---|---|---|---|

| Foam Inserts | Polyethylene (PE) foam, polyurethane foam, foam sheets, die-cut foam | Excellent cushioning, shape customizability, clean appearance, great for fragile products. | More expensive than simple cardboard; some foams have environmental disposal issues; production lead time. |

| Cardboard / Paperboard Inserts / Dividers | Corrugated cardboard, fiberboard, kraft board | Cheap, lightweight, easier to recycle, quick turn around. | Less shock absorption, may shift in transit; less premium look. |

| Molded Pulp / Molded Fiber | Recycled pulp, molded fiber | Eco-friendly, biodegradable; good for many industries. | Less precision; may be bulkier; limited shape options. |

| Plastic / Thermoformed | PET, PVC, molded plastics | Very precise shape; high durability. | More cost; environmental and perception issues; heavier; sometimes regulatory issues. |

| Hybrid Inserts | Foam + cardboard + fabric + inserts for anti-static, etc. | Combine protection & aesthetics; mix functionality. | More complex to design & costlier; assembly more involved. |

How to Design / Choose the Right Insert

Here’s a step-by-step guide to making good choices if you want custom box insert, custom boxes with foam inserts, or something similar.

1.Understand Your Product Needs

- Fragility: is it delicate? glass, electronics, sharp edges?

- Shape & weight: unusual shapes need more precise fit.

- Number of parts: multiple smaller parts may need separators or insert pockets.

2.Estimate Shipping / Handling Conditions

If shipped long distances, rough handling, possible drops, vibration, humidity, etc.

3.Choose Material & Density

For foam inserts: foam density, compression deflection, ability to rebound after compression.

4.Design for Fit + Aesthetics

- Precision cutting or custom shaping so the product fits snugly.

- Consider color & finish of insert.

- Branding: sometimes foam inserts can be embossed, colored, or have logos.

5.Sustainability & Compliance

- Choose recyclable or biodegradable materials if possible.

- Avoid materials with problematic environmental impact.

- Look into regulatory requirements (especially in medical, food, aerospace).

6.Test It

Test by simulating shipping drops / vibration. Walk through the unboxing: is it easy to remove products? Is opening safe and pleasant?

Case Studies & Data

To bring theory into real life, here are a couple of examples + numbers that illustrate the impact of good inserts.

- PSAP Custom Foam Inserts Case: A client in the aerospace/medical sector had high losses (damage claims about $150,000/year) because products moved inside crates. After using custom foam insertsthat were shaped exactly to the product (no movement), the loss claims dropped to near zero. Shipping damage virtually eliminated.

- Market Trends: The foam packaging inserts marketis projected to grow steadily: more than 55% of high-end medical and automotive packaging solutions now use foam inserts. And forecasts suggest the foam inserts market will reach USD ~28,877.6 million by 2033, growing at ~5.4% CAGR.

- Unboxing Experience & Customer Loyalty: Studies show that memorable unboxing experiences significantly increase customer satisfaction and repeat purchases. Brands that invest in unique packaging see higher engagement and social sharing.

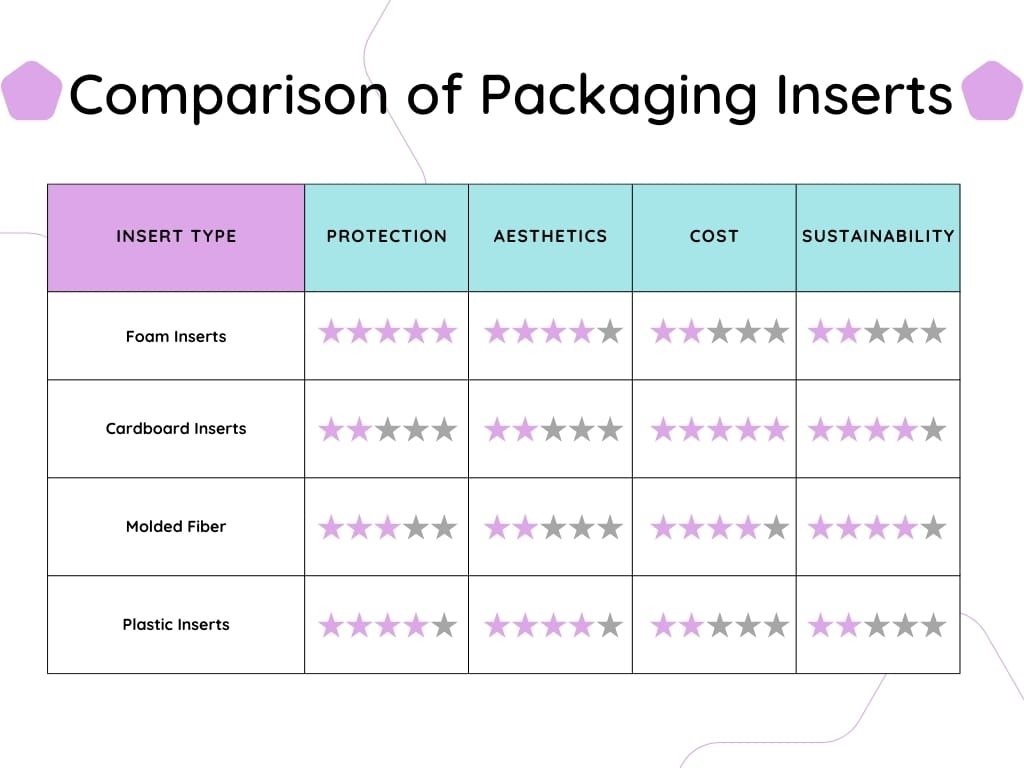

Visual: Comparison of Inserts by Priority

Here’s a simple chart showing how different insert types rank, depending on what you prioritize (Protection, Aesthetics, Cost, Sustainability).

(★ = 1 low; ★★★★★ = 5 high)

You might see some trade-offs: a custom box with foam insert usually scores high for protection and presentation but may lag behind cardboard or molded fiber in cost and sustainability if you’re not using eco-friendly foam.

Common Mistakes & How to Avoid Them

Even when someone decides to use custom box inserts, things can go wrong. Here are pitfalls and tips:

| Mistake | Result | How To Avoid It |

|---|---|---|

| Insert too loose or too big | Product shifts → damage; unboxing feels sloppy | Measure precisely; prototype; use snug shapes |

| Insert too hard / dense | Difficult to remove product; maybe damage on edges | Choose proper foam density; consider easing edges |

| Over-packaging / too bulky | Increased shipping cost; more material waste | Optimize design; minimal but sufficient protection |

| Using non-branded or generic inserts in premium product boxes | Cheapens presentation; dilutes brand identity | Custom design; use interesting materials or colors |

| Ignoring environmental impact | Bad PR; customer backlash; regulatory issues | Use recyclable or biodegradable materials; source responsibly |

How Much Does It Cost?

This depends heavily on material, quantity, complexity, and supplier. To give rough ballparks:

- Simple cardboard inserts/dividers: low cost per unit once tooling/design is done.

- Basic foam cut inserts (flat sheet, simple die-cut): moderate cost.

- High-precision foam inserts (multi-layer, contoured, logos, anti-static): higher cost.

- Plastic molded inserts: highest tooling + per-unit cost, especially for small runs.

Often the extra cost is offset by fewer returns, less damage, better customer satisfaction, which translates to repeat business and word-of-mouth (not to mention lower replacement costs).

Putting It All Together: Example “Journey” of Using Inserts

Here’s an example of how a small business might go from ordinary box → custom mailer box with foam insert.

- The business sells handcrafted jewelry. Initially, pieces come in small pouches inside generic mailer boxes. Complaints: pieces shift, sometimes tarnish or scratch. Unboxing feels “cheap”.

- They consult with a packaging supplier. Decide on a custom box with insert: mailer-style outer box, foam tray insert with a small cut-out for jewelry, velvet-like finish for soft touch. They also imprint the logo on the foam and include a thank you note.

- Prototype and test: drop tests, customer feedback. Adjust foam density (so jewelry lifts out easily but stays secure), adjust box size to reduce wasted space.

- First orders arrive. Customers post pictures, comment on presentations. Damage returns drop. Repeat purchases increase. Slight cost per unit is higher, but offset by fewer replacements and better word-of-mouth.

Tips & Trends: Something to Keep an Eye On

- Eco-friendly foam: bio based, recyclable PE foil foams, compostable molds.

- Smart inserts: integrating QR codes, RFID, or sensors in packaging, or inserts that have dual function (e.g. foam tray that becomes a display stand).

- Minimalist & clean designs: less is more. Many brands go for simpler inserts with premium materials rather than ornate.

- Personalization: even small touches like “your name” embossed, handwritten note, etc., within the box.

Summary

Box inserts — from custom foam inserts to cardboard dividers — are more than just packaging interior pieces. They protect, organize, elevate, and tell your brand’s story. Whether you’re looking for custom insert for boxes, custom boxes with foam inserts, or custom mailer box with insert, the right design makes a difference in cost savings, customer delight, and perception.

If done well, with attention to material, design, and sustainability, inserts turn a simple package into a memorable experience.