Imagine walking into your freezer, reaching in, and pulling out a cardboard box of ice cream—a perfect block, crisp edges, maybe a layer of wax inside, waiting to be sliced or wedged between wafers. For many, this is nostalgia; for younger shoppers, this is an oddity. Over recent decades, ice cream boxes—especially rectangular, blocky cartons—have mostly disappeared from shelves. They’ve been replaced by round tubs, “squrounds” (hybrid square-round shapes), pint containers, and more recently, premium packaging, subscription boxes, and gift-oriented formats.

What happened to the ice cream box? Let’s explore the history, the practical/economic/consumer factors, and whether boxes might make a comeback—especially in forms like custom ice cream boxes, or ice cream gift boxes and ice cream subscription box offerings.

A Brief History: Where the Box Came From

- In the early and mid-20th century, many ice creams were sold in rectangular/waxed paperboard boxes. These are what many of us remember: brick-shaped units, often with flaps on top or ends. They were easy to stack, ship, store.

- Cardboard (often with a wax or moisture-barrier lining) was relatively inexpensive, printable for branding, and could be made in standard sizes.

- Over time the industry moved toward round containers, tubs, and “squrounds” (rounded square/rectangular shapes) for reasons we’ll cover.

Key Drivers: Why Ice Cream Left the Box

Here are the major reasons rectangular, rigid box packaging declined in favor of other styles:

| Factor | What Boxes Did Poorly / Compared to Tubs / Squrounds / Cylinders |

|---|---|

| Manufacturing and Logistics | Boxes often needed pre-assembly before filling. Tubs or squrounds often arrive “ready to fill,” reducing labor and time. |

| Scooping Convenience & Usability | The deep corners of rectangular boxes mean “knuckle muck” — hard to reach corners, messy for consumers. Round and squround shapes allow scooping out more easily. |

| Shelf & Freezer Efficiency | Freezers (in trucks, retail, or home) are often designed in ways that favor more standardized, stackable, curved containers. Also, square edges may block airflow; round or hybrid shapes help with better temperature consistency. |

| Thermal / Microenvironment / Melting | More surface area (relative to volume) exposed in what used to be square – bricks leads to faster heat transfer, more vulnerability to freezer burn or melting. Round or hybrid shapes help reduce that. |

| Packaging Integrity / Sealing | Traditional cardboard boxes often open on both ends or have flaps; lids on tubs or squrounds tend to offer better seals, reducing air ingress and moisture loss. |

| Consumer Perception & Branding | Tubs allow for visible design, clearer branding; consumers may see round tubs as more “premium.” Also, trends—of convenience, resealability, portion control—favored tubs/pints. Boxes might give memory appeal but less flexibility. |

So in short: manufacturing cost & speed, usability & experience, preservation of quality, and marketing all favored non-box formats.

The Rise of the “Squround” & Other Shapes

One of the shapes that replaced classic cardboard boxes is the “squround”—a portmanteau of square + round. It looks like a rectangular shape with rounded edges (or sometimes closer to an oval-ish rectangle). This shape tries to capture some benefits of both worlds: stackability, branding surface, but also ease of scooping and thermal efficiency.

Some statistics/trends:

But… The Box Still Lingers — and Could Be Coming Back

While rectangular, cardboard ice cream boxes have largely fallen out of mainstream commercial use, they haven’t disappeared completely. Some niche, artisanal, or premium brands have been reviving the box for nostalgia, design differentiation, or specialty purposes.

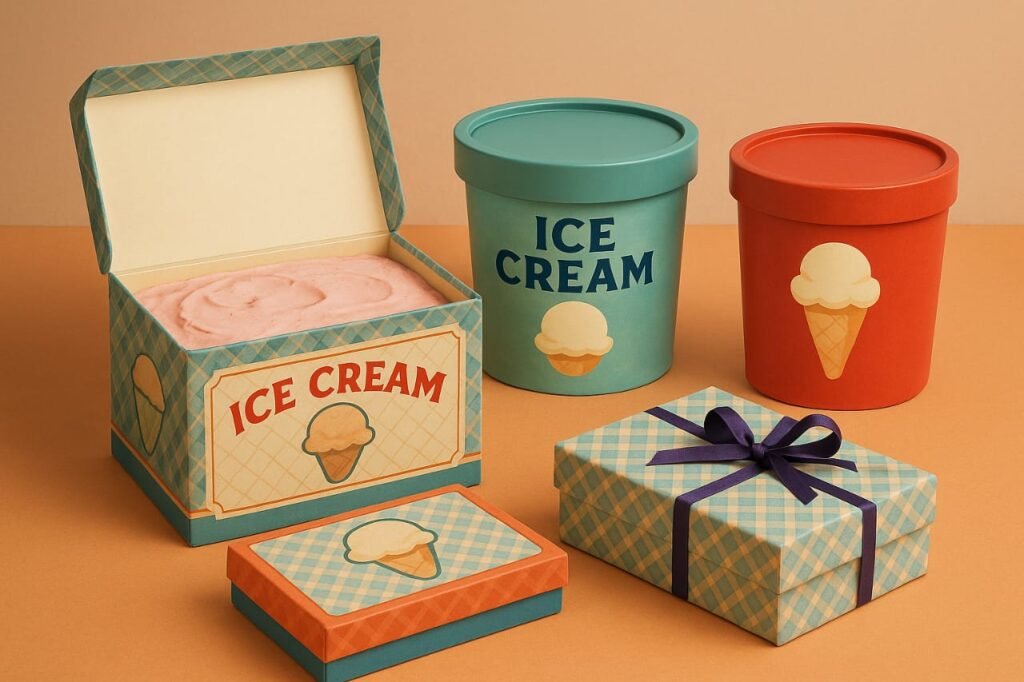

Also, in contexts like ice cream subscription box, ice cream gift box, or when using custom ice cream boxes for promotional or limited edition products, the box still has appeal. It provides a canvas for branding, artistry, and an “unboxing” experience that tubs don’t always offer.

Anecdotal findings:

- Some nostalgic lovers notethat in certain countries or brands, brick-style boxes are still sold, sometimes under “sliceable” or “block” ice cream offerings.

- Wholesale / B2B ice creamproviders (“brick” formats) are sometimes still used for restaurants, parlors. Cardboard boxes are useful in those settings.

Case Study: Thrifty Ice Cream & the Phase-Out of Boxes

An illustrative example is Thrifty Ice Cream (in the U.S.).

- Historically sold packaged ice cream by the half-gallon in simple, waxed-paper boxes with interlocking flaps.

- These “brick boxes” were phased out around 2008. The company moved toward “squrounder” cartons, and more rounded containers.

This transition reflects broader industry movement: old style box formats become harder to maintain, less cost-efficient, less aligned with modern expectations.

Visual Comparison

Here is a conceptual table comparing performance/characteristics of typical box vs tub/squround vs gift/subscription box formats:

| Characteristic | Traditional Cardboard Box | Squround / Round Tub / Modern Tub | Ice Cream Gift Box / Custom Box / Subscription Box |

|---|---|---|---|

| Cost to produce (for large scale) | Moderate-low materials, but higher labor/assembly | Lower labor time, higher cost for moulded components but efficient at scale | Higher cost per unit, lower scale; more design/packaging investment |

| Branding surface & presentation | Good flat surfaces, but works less well once frost or freezer wear sets in | Moderate—curved surfaces challenge print, but lids provide space; squround gives compromise | Excellent—fully customisable; opportunity for premium finishes, graphics, textures |

| Usability (scooping, handling) | Poor—deep corners, awkward to reach edges; may lead to mess | Much better—rounded edges, lids, easier to scoop | Depends on design; can combine shapes or include tools or separators |

| Thermal performance / freezer burn risk | Higher—more exposed surface area relative to volume, more edges, less efficient sealing | Lower risk—tighter seals, less exposed surface; better shape for cold retention | Can be designed well or poorly; gift/subscription boxes often intended for short haul or presentation more than long term storage |

| Shelf / logistics efficiency | Bulky, awkward; may require more protection in transport | Easier for stacking, automated filling, lid sealing; standardized shapes help | Usually less optimized for large logistics, more for retail display or shipping to end consumer |

Does Nostalgia & Premium Demand Push Backboxes? (Bringing Back the Box)

There is some momentum for reviving or reinventing ice cream box-style packaging, especially under certain themes:

1.Custom Ice Cream Boxes – For smaller, artisanal makers, custom boxes allow branding, storytelling, limited edition flavors. They are used as ice cream gift box offerings: sets of small samples in individual custom boxes, or bundling flavors.

2.Ice Cream Subscription Boxes – These often ship ice cream (or frozen treats) to consumers; packaging becomes part of the experience. A subscription box might use rigid or insulated boxes with internal liners; or might use custom ice cream boxes for each flavor. The tactile and visual experience is part of the value.

3.Environmental & Sustainability – Some brands may return to heavier-duty paperboard or cardboard boxes with biodegradable linings, or use wax/plant-based coatings, to reduce plastic use. The box shape historically has been paper/cardboard, which is more biodegradable, though the issues of lining, heat sealing, and insulation remain.

4.Vintage Design & Marketing – Nostalgia sells. Products that evoke “ice cream from grandma’s freezer” sometimes adopt block-style packaging. It becomes part of the brand identity and can differentiate among many round tub competitors.

Why the Box Could Be Hard to Fully Return

Even with demand for custom boxes, gift packaging, etc., there are structural reasons they won’t fully replace tubs and squrounds in mass markets:

- Cost & Production Speed: Boxes require more steps (assembly, sealing, perhaps manual labor). In large scale production, speed is crucial.

- Shelf Life and Quality: Ensuring the box is sufficiently moisture- and cold-resistant, preventing freezer burn, maintaining seal integrity, is harder for some box designs.

- Consumer Preferences: People now expect resealable lids, easier scooping, portability. Tubs deliver better on those expectations.

- Storage & Retail Logistics: Retail freezer layouts, display cases, supply chains are optimized for standard shapes (round, squround, pints, etc.). A resurgence of non-standard boxes would require adaptations in storage, transport.

Possible Future Scenarios

Given all that, here are some “what ifs” or predictions for how boxes might re-emerge (or not) in ice cream packaging:

- Eco-friendly revival: advances in biodegradable coatings and ice cream-safe cardboard could reduce technical drawbacks of boxes, making cardboard box ice cream more viable.

- Hybrid packaging: maybe boxes lined with wax or biodegradable film, lids that seal, or boxes designed for short-term display rather than long-term freezer storage.

- Gift / artisanal niche expanding: in the artisanal market, or among boutique ice cream shops, ice cream gift boxes or custom ice cream boxes might become prestige items, even if the mass-market stays tub-based.

- Subscription models driving design: as ice cream subscription boxservices grow, packaging for shipping, presentation, unboxing becomes more important—companies might return to more rigid, custom boxes (with insulation) to differentiate.

Conclusion

So, why doesn’t ice cream come in a box anymore? In mass production and everyday consumer purchase, boxes are lost out to shapes that are cheaper to fill, easier to scoop, preserve quality better, stack and store more efficiently, and better align with consumer expectations like resealability.

However, the box hasn’t totally disappeared. In niches—gifting, subscription boxes, boutique / artisanal ice cream, nostalgic branding—there’s space for ice cream boxes, custom ice cream boxes, ice cream gift box, cardboard box ice cream to shine. If environmental technology improves (better cardboard liners, coatings, insulation), and consumer demand for sustainable, beautiful packaging remains strong, boxes might enjoy a modest revival.