Selecting the right water bottle box shapes a good first impression and protects products from damage. Companies should choose Custom Water Bottle Boxes or a water bottle gift box that matches their product and target audience. A well-designed Water Bottle Packaging Box and Custom Water Bottle Box Packaging not only supports brand image but also helps with cost control and builds customer loyalty.

A good first impression and attractive water bottle box design boost brand trust and loyalty.

Water bottle gift box packaging and design influence purchase decisions and enhance user experience.

Key Takeaways

Choose water bottle boxes that protect products well and match your brand to build trust and attract customers.

Select packaging materials and box sizes carefully to reduce damage, control costs, and support sustainability goals.

Use customized, eco-friendly packaging and clear labels to connect with consumers and meet safety and environmental standards.

Packaging Needs

Bottle Size

Understanding the product and target market helps businesses select the right packaging for bottles. The beverage industry uses a range of bottle sizes, each with unique packaging requirements. The table below shows common sizes and their impact on packaging:

Packaging Material | Common Sizes | Advantages | Disadvantages | Impact on Packaging Requirements |

|---|---|---|---|---|

Glass | 375 mL, 750 mL | Superior barrier; recyclable | Heavy; fragile | Needs careful handling; increases shipping weight |

PET | Varies | Lightweight; strong | Needs oxygen scavengers | Allows lighter packaging; needs design for durability |

Aluminum cans | 375 mL | Lightweight; easy to transport | Low internal strength | Enables portability; needs tamper-evident features |

Bag-in-box | 3 to 5 L | Larger volume | Susceptible to oxygen permeation | Suitable for bulk packaging; needs oxygen management |

Tetra Pak® | 200 and 500 mL | Lightweight; stackable | Single-use | Easy transport; limited recyclability |

Bottle capacity strongly influences the weight and material usage in beverage packaging. Larger bottles often provide better cost efficiency per volume, but they may increase plastic waste if not managed properly. Carbonated beverage bottles require thicker walls, which impacts packaging design and cost. Consumer preferences for small, medium, or large bottles also affect packaging choices, balancing convenience, health, and sustainability. Businesses must consider sizing to meet market demands and ensure product safety.

Wine bottles commonly use 750 mL as a standard size, with 375 mL and 1.5 L also popular.

Spirits typically come in 750 mL bottles, with larger sizes such as 1 L and 1.75 L.

Beer packaging varies, including 12-ounce cans, 22-ounce bottles, and 64-ounce growlers.

These sizes influence packaging by dictating material choice, weight, and transport efficiency.

Box Selection

Selecting the correct box for bottles involves balancing practicality, cost, and aesthetics. Businesses consider several factors when choosing between different types of water bottle boxes:

Branding opportunities through customization and logo placement

Size and weight for convenience and usability

Product durability and trusted brands

Packaging Type | Key Factors Considered | Suitability & Features |

|---|---|---|

Cardboard Retail Boxes | Cost, bottle type, consumer expectations, customization, branding | Customizable, ideal for retail display, gift packaging, often used for glass bottles |

Cost, durability, protection, stacking, labeling, shipping efficiency | Durable, lightweight, cost-effective, good for plastic bottles, easy stacking and labeling | |

Shrink Plastic | Protection during transit, tamper-proof sealing, branding options | Mainly for plastic bottles, heat-shrunk to fit tightly, protects from scratches, allows printing on wrap |

Shrink Plastic + Cardboard Pallets | Protection, stability, branding, volume handling | Used for large volumes, combines cardboard tray with shrink wrap, prevents rattling, suitable for plastic or glass |

Wood | Protection, aesthetic appeal, premium branding, eco-friendliness | Premium option, heavy and costly, ideal for wine bottles, unique and eco-friendly alternative, good for gifts |

Box design and structure affect both practicality and cost. Custom rigid boxes made from sturdy materials like cardboard or corrugated fiberboard provide durability and protection for fragile bottles. Their structural design ensures a snug fit, minimizing movement and damage during transport. These boxes can be reused multiple times, supporting long-term cost savings. Customizable design elements such as colors, textures, and personalized features improve brand presentation and justify packaging expenses. Using recyclable or biodegradable materials and minimizing waste production further supports cost-effectiveness and appeals to eco-conscious consumers.

Choosing the correct box size is crucial to minimize product movement during shipping. Products should fit snugly within boxes, leaving just enough room for protective cushioning. Minimizing empty space prevents items from shifting and sustaining damage. Oversized boxes cause unnecessary movement and require more filler material, increasing risk of damage and shipping costs. Properly filled right-sized boxes maintain shape better and withstand external pressures, protecting the product from collisions with box walls.

Tip: Selecting a right-sized box minimizes empty space, distributes impacts across the box structure, and reduces the need for void fill materials. This enhances the overall structural integrity and protects bottles from vibrations, shocks, and drops during shipping.

Beverage Packaging System

A complete beverage packaging system includes primary, secondary, and tertiary packaging. Each component interacts to protect bottles and maintain product quality.

Shock Absorption: Materials like bubble wrap and foam inserts cushion bottles, absorbing impacts and preventing damage during transportation.

Movement Control: Air pillows and void fillers stabilize bottles inside the packaging, minimizing shifting and friction.

Environmental Protection: Moisture barriers and thermal insulation protect against moisture, temperature changes, dust, and contaminants.

Customized Packaging: Tailored packaging fits the specific shape and fragility of bottles, reducing movement and wear.

Labeling and Handling Instructions: Clear markings guide handlers to treat bottles carefully, reducing mishandling risks.

Quality Assurance and Testing: Drop and vibration tests ensure packaging effectiveness.

Continuous Improvement: Ongoing updates to packaging materials and methods address emerging risks and enhance protection.

Packaging systems for beverages use materials designed to provide barriers against contamination and environmental degradation. These materials interact with the beverage, influencing flavor, odor, appearance, and texture. Proper selection of packaging materials with appropriate barrier properties prevents off-flavors, spoilage, and quality loss. Communication along the supply chain ensures that packaging materials meet the specific needs of the beverage product, supporting protection throughout manufacturing, storage, and distribution.

Understanding the target market also shapes beverage packaging choices. Typography, color schemes, imagery, and physical design elements are tailored to consumer preferences. For example, bold fonts and bright colors attract energetic consumers, while elegant fonts and minimalist designs appeal to luxury buyers. Sustainability features in packaging, such as recycled or biodegradable materials, attract eco-conscious consumers and build brand loyalty. Packaging acts as an emotional trigger and storytelling tool, aligning with target market values to attract attention, build trust, and foster long-term relationships.

Protection & Branding

Water Bottle Box Materials

Selecting the right materials for a water bottle box ensures durability, leak prevention, and protection from external factors. Aluminum bottles with silicone gaskets offer superior leak prevention. Silicone gaskets create a watertight seal that resists chemical reactions and withstands temperature changes. An empirical study found that aluminum bottles with silicone gaskets retained 99.8% of their contents after six months. In comparison, plastic bottles with rubber seals retained only 92%. Aluminum’s natural oxide layer prevents rust and degradation, maintaining product quality and freshness longer than plastic containers. Plastic can absorb chemicals and degrade under UV light, which may affect the taste and safety of the beverage.

Cap liners and seals play a critical role in water bottle packaging. They prevent leaks, evaporation, and contamination by creating secure barriers between the container and its closure. Different liner materials offer varying levels of moisture resistance, chemical compatibility, and seal integrity. For example, induction liners provide airtight, tamper-evident seals ideal for liquid products. Foam liners help prevent leaks but may not create airtight seals. The choice of liner depends on the product type, environmental conditions, and regulatory requirements.

Liner Type | Description | Benefits | Limitations | Common Uses |

|---|---|---|---|---|

3-Ply Foam (F217) | Compressible polyethylene foam, general purpose | Resistant to taste/odor, low moisture transmission | Does not create airtight seal | Household, food, cosmetics |

Polyethylene Foam | Compressible foam, economical | Compatible with various containers | Poor resistance to hydrocarbons, no airtight seal | Household, water-based products |

Pressure Sensitive | Foam liner with adhesive side | Preserves freshness of dry products, no extra equipment needed | Not suitable for liquids, limited shelf life | Dry powders, thick liquids |

Induction | Layers of pulpboard, wax, foil, heat sealed | Tamper-evident, airtight, prevents leakage | Requires induction sealing machine, compatibility testing needed | Food, liquids, pharmaceuticals |

Poly Vinyl | Vinyl coating on pulpboard | Good chemical resistance, works with oil/water | Not for active hydrocarbons or bleaches | Alcohol, mild acids, cold fill |

Polyseal | LDPE cone liner creating wedge seal | Leak-proof, prevents evaporation and contamination | N/A | Liquid products |

Vacuum bottle packaging uses a multi-material approach to prevent moisture ingress and protect product quality. Outer packaging often uses high-density corrugated cardboard with moisture-proof coatings. Inner layers may include plastic films like OPP or PET, which act as barriers against water vapor and air. Aluminum foil serves as an inner wrapper or buffer layer, offering excellent barrier properties. This combination ensures effective protection from moisture and environmental factors, balancing performance with cost and environmental impact.

High-quality packages rely on the right material choices for bottled water labels and boxes. The durability of these materials affects the overall protection and shelf life of the product. Companies must consider the cost of water bottle labels, print quality, and the ability to withstand handling and shipping. Using the right materials and print methods ensures that labels remain legible and attractive throughout the product’s lifecycle.

Brand Identity

Packaging design plays a vital role in communicating brand identity and supporting marketing strategy. Custom labels for water bottles allow brands to create personalized experiences. For example, Coca-Cola’s “Share a Coke” campaign used name customization to engage consumers. Brands use advanced technologies like AI and machine learning to tailor packaging based on consumer behavior and preferences. This approach increases relevance and functionality.

Packaging customization supports exclusive limited editions and modular packaging, improving user experience and fostering loyalty.

Interactive technologies such as QR codes, NFC, and augmented reality transform packaging into an engaging, interactive medium.

Sustainability messaging and eco-friendly materials in customized packaging build consumer trust and align with environmental awareness.

Inclusive design features, such as easy-to-open packages, broaden market reach and improve user experience.

Customized packaging aligns with brand identity by reinforcing brand messages and building recognition. Innovative packaging design trends that break traditional formats create memorable customer experiences. Unique textures, shapes, and augmented reality features enhance consumer interaction. Packaging that visually and tactically reflects brand values, such as luxury or sustainability, helps consumers connect emotionally with the product.

Personalization through packaging inserts like thank-you cards, coupons, or samples increases consumer engagement. Brands use segmentation, targeting, and positioning to tailor packaging personalization to different customer groups. Studies show that 71% of consumers expect personalized brand interactions, and 88% value experience as much as the product itself. Personalization can increase revenues by 5% to 15%, showing its marketing effectiveness.

Customized packaging creates anticipation and excitement during the unboxing experience. Sensory engagement through visual appeal, tactile materials, scents, and sounds makes the experience memorable. Surprise elements like personalized notes or free samples delight customers, increasing satisfaction and repeat purchases. Social sharing of unboxing experiences on platforms like YouTube and Instagram amplifies marketing reach and consumer engagement.

Tip: Brands should monitor packaging design trends and update their packaging regularly to maintain consumer interest and stay ahead of competitors.

Compliance

Water bottle packaging must comply with strict regulations and quality standards in major markets. In the US, packaging must meet FDA regulations for food contact materials, including Good Manufacturing Practices and specific labeling requirements. Consumer safety regulations require testing for harmful substances such as lead and other chemicals. Agencies like the Consumer Product Safety Commission oversee these requirements. Labels must clearly state product contents, manufacturer information, country of origin, and safety warnings.

In the EU, environmental regulations such as the RoHS Directive restrict hazardous substances in products, including packaging. Voluntary standards like ISO 14001 guide manufacturers in reducing environmental impact. Compliance audits and quality control processes ensure ongoing adherence to these regulations and build consumer trust.

The EU has banned bisphenol A (BPA) in food contact materials, including polycarbonate water bottles.

Polycarbonate bottles containing BPA cannot be placed on the EU market after July 20, 2026.

All polycarbonate bottles must be removed from the market by January 20, 2029, and replaced with BPA-free options.

PET is recommended as a BPA-free alternative, offering recyclability, lower carbon emissions, and compliance with stricter safety standards.

Manufacturers must evaluate current packaging materials and transition to BPA-free options to comply with these regulations.

Packaging suppliers demonstrate compliance by implementing rigorous inspection systems and documenting findings. They categorize defects to track non-conformance trends and take corrective actions, such as equipment adjustments and employee retraining. Suppliers use standardized checklists, SOP templates, and centralized document repositories to maintain audit trails and support regulatory compliance. Adhering to recognized industry certifications, such as GFSI-accredited schemes and ISO standards, helps suppliers prove their commitment to safety and quality.

Suppliers follow Good Manufacturing Practices to ensure consistent product safety and integrity.

They obtain ISO certifications, such as ISO 9001 and ISO 22000, to demonstrate compliance with global quality and food safety standards.

Compliance with OSHA standards maintains workplace safety.

Suppliers invest in advanced safety features in machinery, such as sensors and emergency stops.

Routine employee training and clear safety protocols support ongoing compliance.

Regular audits and inspections identify and address safety gaps.

Predictive maintenance prevents equipment failures.

Suppliers stay informed and adapt to evolving regulatory changes.

Comprehensive documentation, including training records and inspection reports, supports compliance.

Water bottle labeling strategies must also meet regulatory requirements. Labels must use durable materials and print methods to ensure legibility and safety information remain intact. The cost of water bottle labels depends on material choices, print quality, and compliance needs. Companies should select materials and print methods that balance durability, quality, and regulatory requirements.

Note: Staying updated on packaging regulations and quality standards helps companies avoid costly recalls and maintain consumer trust.

Sustainable Beverage Packaging

Eco-Friendly Options

Companies now prioritize packaging that supports sustainability and protects the environment. They select materials that are renewable, biodegradable, recyclable, or plant-based. Plant-based packaging reduces reliance on fossil fuels and lowers greenhouse gas emissions. These materials break down naturally, minimizing plastic pollution. Manufacturers use crops like corn, sugarcane, and potatoes to create bioplastics, mycelium, bagasse, and pulp from recycled paper. Biodegradable packaging materials, such as bioplastics and mycelium-based products, decompose quickly and reduce landfill waste. Paper and cardboard offer recyclability and biodegradability when sourced responsibly. However, production requires water, energy, and chemicals. Plant-based packaging supports circular economy principles, though industrial composting and land use remain challenges.

Environmental Impact Highlights | Challenges and Considerations | |

|---|---|---|

Paper and Cardboard | Renewable, recyclable, biodegradable; high recycling rates; reusable. | Requires water, energy, and chemicals; poor forestry management risks. |

Biodegradable Materials | Break down naturally, reducing pollution and landfill waste; compostable options enrich soil. | Often require industrial composting; contamination risk; limited infrastructure; niche and costly at scale. |

Plant-Based Packaging | Derived from renewable crops; reduced carbon footprint; biodegradable; aligns with circular economy principles. | Land use concerns; need for industrial composting; infrastructure development needed; potential cost limits. |

Recyclable & Reusable Bottles

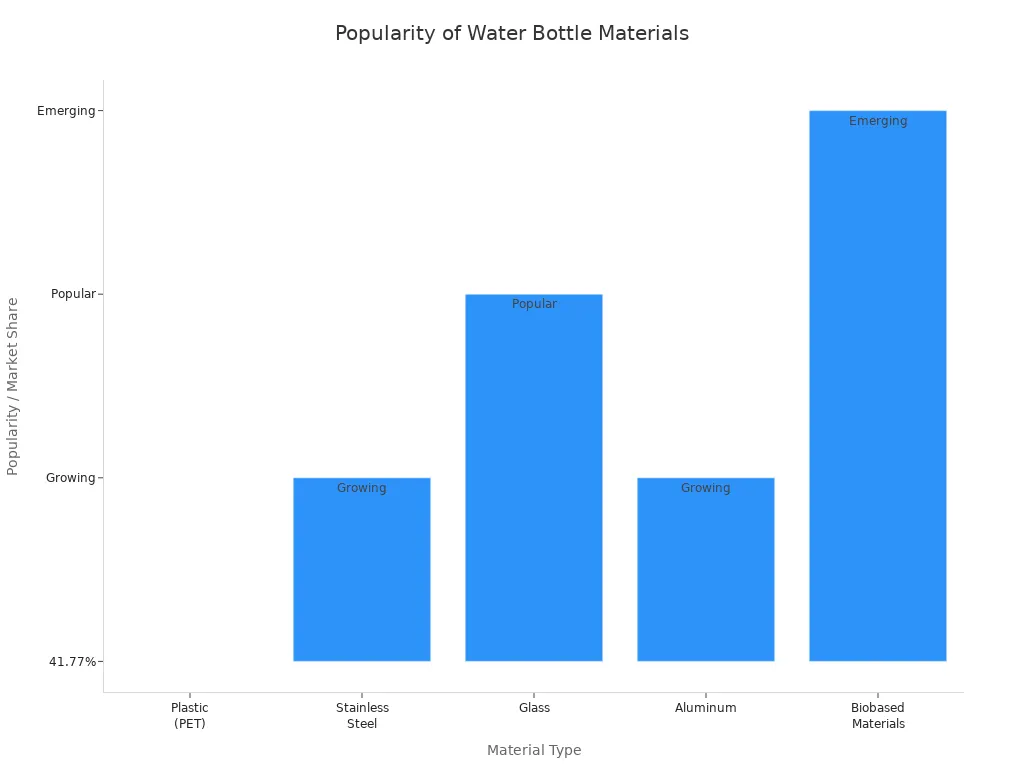

Businesses choose bottles made from recycled stainless steel, glass, aluminum, and biobased materials to improve sustainability. Stainless steel bottles offer durability, recyclability, and long-term value. Glass bottles provide chemical stability and safety, though they are heavier and breakable. Aluminum bottles are lightweight and recyclable, but require multiple uses to offset carbon emissions. Plastic bottles made from recycled PET remain popular due to cost and convenience, but brands now favor recycled and biobased options. Paper water bottles designed for biodegradability suit bulk business use. The chart below shows the market share of popular recyclable and reusable bottle materials.

Material Type | Popularity/Market Share | Key Attributes and Trends |

|---|---|---|

Plastic (PET) | Lightweight, convenient, cost-effective; most common plastic used; environmental concerns limit growth. | |

Stainless Steel | Growing | Durable, eco-friendly, BPA-free; increasing adoption for sustainable bottles. |

Glass | Popular | Durable, eco-friendly; preferred for longevity and sustainability. |

Aluminum | Growing | Durable and recyclable; used in some recycled bottles. |

Biobased Materials | Emerging | Made from natural feedstocks; reduce reliance on petroleum plastics. |

Customer Appeal

Eco-conscious consumers value sustainable beverage packaging and recyclable bottles. Surveys show that 78% of U.S. shoppers prioritize sustainable brands, and 43% are willing to pay extra for sustainable packaging. Millennials and Gen Z shoppers consider sustainability important in purchasing decisions. Minimalist packaging appeals to consumers by reducing material use and signaling environmental responsibility. Brands that communicate sustainability authentically build trust and loyalty. Practical design features, such as durability and ease of cleaning, influence acceptance of reusable packaging. Companies evaluate packaging manufacturers for sustainability considerations, including cradle-to-cradle manufacturing, life cycle assessment, and product stewardship. They measure carbon footprint, analyze waste generation, and ensure compliance with regulations. Businesses also assess labels for print quality, recyclability, and durability to meet market demand and maintain product quality.

Tip: Brands should collaborate with packaging suppliers early in the design process to integrate sustainability and ensure labels meet both print and recyclability standards.

Companies create a strong impression by selecting water bottle boxes that balance protection, branding, cost, sustainability, and customer experience. Consulting packaging experts and requesting samples helps avoid common mistakes. The table below highlights how labels influence business success and customer satisfaction.

Step | Impact on Business and Customers |

|---|---|

Choosing durable materials | Protects products and builds trust |

Using accurate labels | Ensures compliance and enhances brand loyalty |

Improves fit, quality, and visual appeal | |

Aligning with market trends | Meets consumer expectations and drives growth |

Optimizes cost, sustainability, and protection | |

Updating labels regularly | Maintains relevance and regulatory compliance |

Designing clear labels | Reduces confusion and supports customer experience |

Testing labels durability | Prevents damage and maintains product integrity |

Selecting eco-friendly labels | Appeals to eco-conscious consumers |

Customizing labels | Strengthens brand identity and recognition |

Including safety labels | Increases consumer confidence |

Using labels for storytelling | Connects emotionally with customers |

Ensuring labels legibility | Improves accessibility and user satisfaction |

Integrating digital labels | Enhances engagement and information access |

Monitoring labels trends | Keeps packaging competitive |

Evaluating labels suppliers | Ensures quality and cost-effectiveness |

Refines packaging strategy and boosts loyalty |